- Home

- Products

- Forged Valves

- Inconel 601 Forged Valves

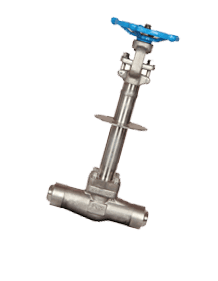

Inconel 601 Forged Valves

Inconel 601 Forged Valves, Inconel Alloy 601 Forged Valves, Alloy 601 Forged Valves, Grade 601 Inconel Forged Valves Suppliers, UNS N06601 Forged Valves, DIN 2.4851 Forged Valves, Alloy 601 Forged Valves Manufacturers in Mumbai, India.

Virgin engineers are one of the leading manufacturers, exporters, and suppliers of high quality Inconel 601 Forged Steel Valves. We offer all types of ferrous and non-ferrous forged steel valves in various standards, designations, custom dimensions, and specifications. Our whole production process is managed by technically skilled staff and professionals who regularly update the production line. Our Inconel forged steel valve comes with an amazing number of features such as high grade quality superiority in the performance. Our offered ranges of valves have a blend of salient features such as resistivity, low maintenance, quality, sturdy finish, robust design, and durability.

Inconel 601 Forged Gate Valve, Alloy 601 Forged Globe Valves, Inconel 601 Forged Check Valves, Inconel® 601 Forged Y-PATTERN Valves, Inconel 601 Forged Valves Exporters, Alloy 601 Forged Integral Flanged End Valves, Grade 601 Inconel Forged Valves, Inconel® 601 Forged Valve, Alloy 601 Forged Valves Supplier in Mumbai, India.

Inconel 601 Flanged End Valve, Inconel Alloy 601 Bellow Sealed Valve, Inconel 601 Cryogenic Valve, Inconel Alloy 601 Forged Bolted Bonnet Valves, Alloy 601 Welded Bonnet Forged Valves.

We are the professional exporter of forged steel valves fabricating them with high quality raw materials under the advanced machines. Availability of sophisticated machines we are able to produce these steel valves in non-standard dimensions which are hard to find.

Inconel 601 Forged Steel Valves are a nickel chromium alloy used for applications that require resistance to heat and corrosion. the Inconel alloy stands out due to its resistance to higher temperature oxidation up to 2200 deg F. Inconel 601 develops a tightly adherent oxide scale resists spalling under the severe thermal cyclic conditions. These forged steel valves have excellent high temperature strength and having great functionality after long exposure to heat. These forged steel valves have resistance to aqueous corrosion, great mechanical strength, readily formable, machinable and weldable.

The properties of Inconel 601 alloy makes it an alloy of broad utility in fields like chemical processing, thermal processing, and more. However, this alloy is not recommended for use in strong reducing and sulfur bearing environments.

This alloy has the ability to resist chloride ion stress corrosion cracking, corrosion resistance in highly pure water, mineral acids, caustic corrosion and more. This version of the alloy is readily weldable with all type of standard welding processes such as arc welding, resistance welding and more. These forged steel valves are manufactured using the forging process to achieve precise dimensions and surface finish.

Our quality assurance simply starts with knowing the requirements of customers and continues until the customer will completely satisfied with delivered products. Our quality control process is well defined and thoroughly implemented in each section of production level. We are continuously enhancing the effectiveness of products and workforce production methods that make us able to reach zero error levels. We also believe in the testing of forged steel valves to determine the quality of made and supplied a range of products. The tests are performed in stages ranges from initial testing of raw materials to end quality inspection.

The initial tests are valve seat leakage test, ultrasonic test, shell leakage test, pneumatic test, hydrostatic test, pitting corrosion test, cryogenic testing, and low temperature testing/ high temperature testing. Other tests are a radiographic test, burst tests and fire safe tests, relief test, transfer valve test, drill stem test, (TV) test, IGC test, etc.

Make an enquiry today at virgin engineers to know more about Inconel 601 Forged Steel Valves.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Inconel 601 | 2.4851 | N06601 | XH60BT | NC23FeA | NCF 601 | NA 49 | NiCr23Fe | ЭИ868 |

| Grade | Ni | Cr | Fe | C | Mn | Al | S | Si | Cu |

| Inconel 601 | 61.5 min | 21.0 - 25.0 | 14 | 0.05 max | 1.0 max | 1.0 – 1.7 | 0.015 max | 0.50 max | 1.0 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1g/cm3 | 1320-1370℃ | 650 min. | 300 min. | 30 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Inconel N06601 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 601 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 601 forged valves standards, inconel 601 Forged valves, alloy 601 forged gate valves, inconel 601 forged globe valves, parker inconel forged valves grade 601, alloy 601 bolted bonnet forged valves size, alloy 601 forged valves pressure sealed bonnet, inconel® 601 forged valves types, alloy 601 forged valves welded bonnet design, alloy 601 forged seal welded valves , inconel 601 socket welded forged valves, alloy 601 forged valves price, alloy 601 flanged end globe valves stockists , inconel 601 flanged end gate valves dealers, inconel® 601 flanged end check valves manufacturer in mumbai, alloy 601 pressure seal bonnet forged valves india, inconel 601 forged pressure seal bonnet valves distributors, inconel alloy 601 bolted bonnet forged gate valves, inconel alloy 601 welded bonnet globe valves stockholder, buy high quality inconel® 601 forged valves, inconel alloy 601 swagelok forged valves, inconel alloy 601 parker forged valves, inconel® alloy 601 screwed forged valves traders.

© Copyright | Virgin Engineers 2021. All Right Reserved.