- Home

- Products

- Valves

- Manifold Valves

- SS 316H Manifold Valves

SS 316H Manifold Valves

SS 316H 5 Way Manifold Valves Suppliers, Stainless Steel 316H Manifold Valves, UNS S31609 Manifold Valves, Stainless Steel 316H Way Manifold Valves, SS 316H 2 Way Manifold Valve, Grade 316H Stainless Steel Instrument Manifold Valves, DIN 1.4401 Manifold Valve, SS 316H Valve Manifold Manufacturers in Mumbai, India.

Virgin Engineers is a reliable stainless steel 316H manifold valves manufacturer and supplier based in Mumbai, India. Our valves are engineered for high-temperature and high-pressure applications, ensuring reliable performance and durability. Crafted with meticulous attention to detail, our SS 316H manifold valves are reliable in challenging settings where high temperatures and harsh fluids are a regular part of operations.

Stainless Steel 316H 5 Valve Manifold, SS 316H Remote-Mount Manifold, SS 316H 2 Valve Manifold Exporters, Stainless Steel 316H Direct-Mount Manifolds, SUS 316H Manifold Valves, SS 316H 3 Valve Manifold, SS 316H Valves Manifolds, Supplier in Mumbai, India.

SS 316H V / VB and VL series Manifolds, SS 316H Hydraulic Manifold, SS 316H Block and Bleed Valves, SS 316H Remote-Mount, SS 316H H Series Manifold Valves, SS 316H Instrumentation Manifold Valves, SS 316H V, AISI 316H Three Way T- Type Manifold Valves, SS 316H Bellows Sealed Manifolds, SS 316H R - Type Manifold Valve, Stainless Steel 316H Double Block Bleed Valve.

We supply a wide selection of 316H stainless steel manifold valves, including 2-way, 3-way, and 5-way designs. Our product range also covers SS 316H valve manifolds, remote-mounted systems, gauge valves, and block and bleed configurations. Each valve is made from high-carbon austenitic stainless steel in accordance with ASTM A182 F316H and ASME B16.34 standards. These 316H grade manifold valves operate efficiently under working pressures up to 6000 PSI and temperatures that go beyond 538°C, making them ideal for heat exchangers, power plants, and chemical refineries.

Our high-temperature SS 316H manifold valves come in standard sizes of ¼”, ½”, ¾”, and 1”, and have connection ends like NPT (ASME B1.20.1), BSPP (ISO 228), and flanged types. We also offer custom 316H valve assemblies made to meet specific installation requirements. Each unit includes important features such as PTFE or graphite stem packing, anti-tamper handles, and different stem tip options like needle, ball, or regulating types for better control and safety.

We serve industries like oil and gas, petrochemicals, marine, and thermal energy. We thoroughly test every 316H stainless steel valve manifold for leakage and durability, adhering to API 598 and MSS SP-99 guidelines. We include full traceability documents with every delivery—this includes dimensional checks, inspection reports, and EN 10204 3.1 mill test certificates. To maintain the quality of our products, we utilize high-grade wooden boxes and moisture-resistant wraps for secure shipping. Virgin Engineers is a reliable provider of SS 316H manifold valves, offering prompt service and readily available stock across India, the Middle East, Southeast Asia, and Europe.

Do you require assistance with specifications or pricing? Are you in search of a reliable manufacturer of 316H manifold valves in India? Reach out to us for immediate assistance, technical guidance, or a tailored quotation.

Specification

ASTM

ASTM A276, A351, A494 / ASME SA276, SA351, SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | WERKSTOFF NR. | UNS |

| SS 316H | 1.4401 | S31609 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

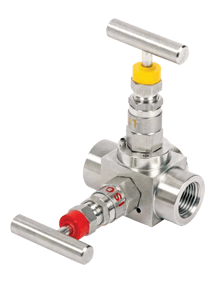

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

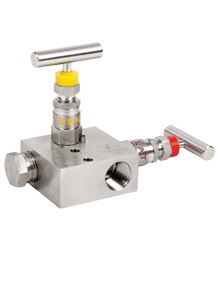

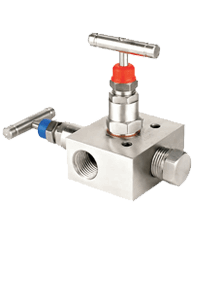

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

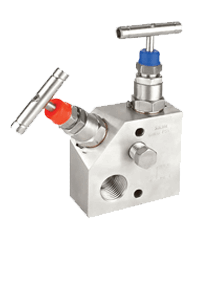

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Stainless Steel S31609 manifold valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on stainless steel 316H manifold valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

grade 316h stainless steel types of manifold valves, 316h ss manifold valve dealers, ss 316h manifold valves price, ss 316h manifold valves stockholder, stainless steel 316h manifold valves manufacturer in mumbai, stainless steel 316h 5 valve remote mounted, ss 316h 2 valve t type manifold valve, ss 316h manifold mounted ball valves, ss 316h manifold valves traders, buy high quality stainless steel 316h manifold valves, stainless steel 316h way manifold price list, ss 316h 2 way manifold valve for pressure gauge, ss 316h manifold valve size, stainless steel 316h manifold 3 valves 2 ways, ss 316h manifold valves manufacturers in india, stainless steel 316h manifold hydraulic valves, ss 316h manifold valves stockists, grade 316h stainless steel manifold valve application, stainless steel 316h manifold valves types, stainless steel 316h 3 valve direct mounted, stainless steel 316h manifold valves distributors.

© Copyright | Virgin Engineers 2025. All Right Reserved.