In process control systems, selecting appropriate valves plays a critical role in ensuring efficiency, safety, and reliability. Instrumentation ball valves are indispensable components that regulate the flow of fluids in various industrial applications. Among the diverse materials available for valve construction, SMO 254 stands out for its exceptional corrosion resistance and durability. This article delves…

Category: valves blog

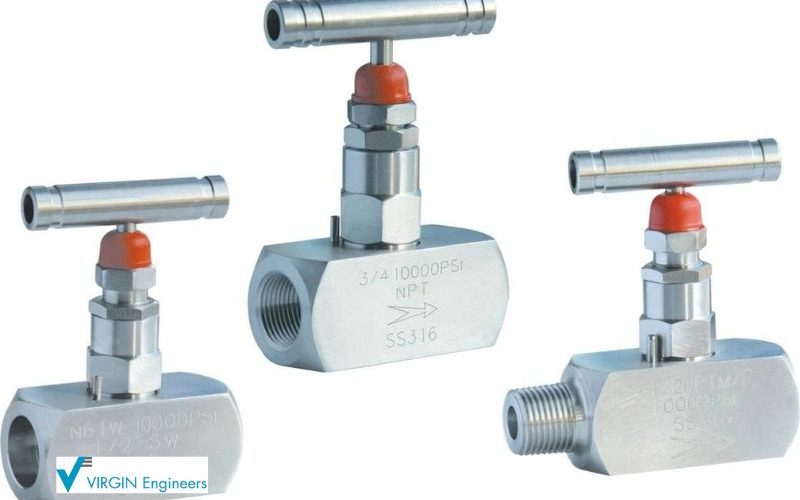

Stainless Steel Needle Valve: Properties, Characteristics, and Applications

A stainless-steel needle valve is a precision control valve designed to regulate fluid flow in various industrial applications. It is constructed using stainless steel, a corrosion-resistant alloy known for its durability and resistance to extreme temperatures. This blog post will discuss the Properties, Characteristics and Applications of Stainless-steel Needle Valves. It helps you to choose…

All You Need to Know About Alloy 20 Needle Valve

Alloy 20, also known as Carpenter 20, is a superalloy composed primarily of nickel, chromium, and molybdenum. Renowned for its excellent corrosion resistance, especially against sulfuric acid, this alloy is a stalwart in severe environments. It’s also notable for its high-temperature strength and ability to withstand pitting and crevice corrosion. These resilient properties make it…

Common Applications of Stainless Steel 310 Gauge Valve

What is stainless steel 310 gauge valve? A stainless steel 310 gauge valve is a type of valve constructed from 310-grade stainless steel, known for its exceptional resistance to corrosion and high temperatures. These valves are designed to withstand demanding industrial environments, offering reliability and longevity. The 310-grade stainless steel composition, often austenitic alloy, provides…

Tips For Proper Installation Of PTFE Ball Valves In Industrial Systems

Ball valves are a popular type of valve used in various industrial applications due to their versatility and ability to effectively regulate the flow of fluids and gases. However, proper installation is critical, especially when using PTFE ball valves. Improper installation can lead to leaks or even system failure, which can cost your business financially…

Why Stainless Steel 347 Needle Valve are a Smart Investment for Offshore Applications

Offshore industries are known to operate in harsh and demanding environments. The high-pressure, high-temperature, and corrosive conditions make maintaining the equipment in good condition challenging. Choosing the right valves, fitting, and other components that ensure safety, reliability, and performance is essential. The stainless steel 347 needle valve is one such component that plays a significant…

What Makes Incoloy 825 Instrumentation Ball Valves Perfect for Seawater Systems?

Seawater systems pose a formidable challenge for most materials. The corrosive nature of seawater, coupled with its high salt content, can lead to rapid material degradation. Enter Incoloy 825 instrumentation ball valves – meticulously engineered to thrive in these unforgiving environments. This post delves into these valves’ attributes, advantages, and wide-ranging applications, highlighting their exceptional…

Unleashing the Power of Titanium Instrumentation Ball Valves for High-Temperature Applications

Industries such as oil and gas, chemical, and petrochemical industries require valves that withstand extreme temperatures and aggressive media. For this reason, titanium instrumentation ball valves have become the go-to solution for such demanding applications. Titanium instrumentation ball valves are made of high-quality titanium material known for being lightweight, durable, and corrosion-resistant. In this blog…

How to Properly Maintain Carbon Steel A105N Manifold Valves for Best Performance

Carbon steel A105N manifold valves are essential in various industries, including oil and gas, petrochemical, and chemical industries. Proper maintenance is crucial to ensure optimum performance and reliability of these valves. This blog post will discuss the essential maintenance tips for carbon steel A105N manifold valves, including cleaning, lubrication, and inspection. What is Carbon Steel…

Expert’s Guide to Stainless Steel 321 Manifold Valves

Stainless Steel 321 manifold valves are essential components in various industrial applications. These valves are highly versatile and can be used in various ways, so it’s important to understand their features and benefits to select the right one for your specific requirements. In this blog post, we’ll dive deep into the characteristics that make Stainless…