- Home

- Products

- Forged Valves

- Titanium Gr2 Forged Valves

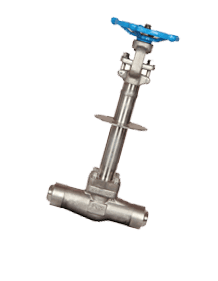

Titanium Gr 2 Forged Valves

Grade 2 Titanium Forged Valves Suppliers, Alloy Gr 2 Forged Valves, DIN 3.7035 Forged Valves, Alloy Gr 2 Forged Valves Manufacturers, Titanium Alloy Gr 2 Forged Valves, UNS R50400 Forged Valves, Titanium Gr 2 Forged Valves Manufacturers in Mumbai, India.

Virgin Engineers is an acclaimed organization catering a wide array of Titanium Gr2 Forged Steel Valves at national and international level. Our industrial experience has helped us in establishing ourselves as one of the foremost manufacturer, supplier, and exporter of forged steel valves. Our products are highly utilized in many industrial applications due to its immaculate attributes and high quality; therefore we offer our products at highly competitive rates to our customers.

We have proficient working employees and qualified professionals that are engrossed in obtaining a quality range product. In addition to it, we source the high-quality raw material from the reputed vendors for its fabrication process. Along with these, we utilize the state of art technologies and most recent machinery in order to achieve accurate and standard finish products. Our goal is to give total customer satisfaction. However, we assure to provide our product in customized shapes, length, thickness, shapes and dimensions as per the requirement & demands of the clients. Moreover, our entire manufacturing procedure is executed as per the norms and regulations of the industry.

Alloy Gr 2 Forged Globe Valves, Titanium® Gr 2 Forged Y-PATTERN Valves, Grade 2 Titanium Forged Valves, Titanium Gr 2 Forged Gate Valve, Titanium Gr 2 Forged Check Valves, Alloy Gr 2 Forged Integral Flanged End Valves, Alloy Gr 2 Forged Valves Supplier, Titanium® Gr 2 Forged Valve, Titanium Gr 2 Forged Valves Exporters Supplier in Mumbai, India.

Titanium Alloy Gr 2 Bellow Sealed Valve, Titanium Alloy Gr 2 Forged Bolted Bonnet Valves, Titanium Gr 2 Flanged End Valve, Titanium Gr 2 Cryogenic Valve, Alloy Gr 2 Welded Bonnet Forged Valves.

Product details:

Titanium Gr 2 Forged Steel Valves are formed with one of the more ductile and softer grades of pure titanium alloy. These valves are high-performance titanium valves that maintain lofty pressures in soaring temperatures. Similarly, these have a high level of oxygen and iron in comparison to other grades that offer superior formability and moderate strength. Therefore these valves ensure excellent corrosion resistant to both mildly and oxidizing environments. On various tempers these grade of valves are cold rolled and get hardened through the cold work procedures only.

The corrosion resistance of this grade of valves comes through a strongly adherent, protective oxide, a stable film that basically forms in the presence of oxygen. Therefore these films offer good resistance to neutral, oxidizing as well as inhibited reducing environments. The hot working of these alloys is functioned at 400 and 600 degree F. Furthermore the stress relieving is done by means of heating at a temperature range of 900 degree- 1100 degree F pursued through the air or slow cooling.

Testing of product

At our manufacturing unit, our professional expert stringently tests and inspects the whole products on various levels of production in order to carry out the quality range and defect free product. These tests are like macro and micro test, cryogenic testing, pneumatic test, hydrostatic test, chemical analysis, pitting resistance test, leakage test.

Documentations:

Documents like NABL test report, fumigation certification, certificate origin of legalized manufacturers, guarantee letter, heat treatment charts, and quality assurance plan are offered to the customers during dispatching.

Packaging and marking:

Our complete range of products is sophistically packed with standard packaging material that ensures the utmost care from severe damage and scratches during shipping. The products are well packed in wooden pallets, wooden cartons, wooden boxes, and wooden cases.

At last the appropriate marking is done on the products. These markings include the specifications, logo, grade, dimensions, size, and lot no and length of the product.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | UNS | WNR. |

| Titanium Gr2 | R50400 | 3.7035 |

| Grade | Ti | C | Fe | H | N | O | Ai | V |

| Titanium Gr2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | - | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900, MPa – 344 | Psi – 39900, MPa – 275 | 20 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Titanium R50400 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Titanium Gr 2 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

Titanium® Gr 2 forged valves types, alloy Gr 2 bolted bonnet forged valves size, Titanium® Gr 2 flanged end check valves manufacturer in mumbai, alloy Gr 2 forged seal welded valves, alloy Gr 2 forged valves welded bonnet design, alloy Gr 2 forged valves price, Titanium alloy Gr 2 swagelok forged valves, alloy Gr 2 pressure seal bonnet forged valves india, Titanium Gr 2 forged pressure seal bonnet valves distributors, Titanium alloy Gr 2 bolted bonnet forged gate valves, alloy Gr 2 forged valves pressure sealed bonnet, Titanium alloy Gr 2 welded bonnet globe valves stockholder, Titanium Gr 2 socket welded forged valves, alloy Gr 2 forged gate valves, Titanium Gr 2 flanged end gate valves dealers, buy high quality Titanium® Gr 2 forged valves, parker Titanium forged valves grade Gr 2, Titanium alloy Gr 2 parker forged valves, alloy Gr 2 flanged end globe valves stockists, Titanium Gr 2 forged valves standards, Titanium Gr 2 forged globe valves, Titanium® alloy Gr 2 screwed forged valves traders, Titanium Gr 2 forged valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.