- Home

- Products

- Valves

- Manifold Valves

- SMO 254 Manifold Valves

SMO 254 Manifold Valves

SMO 254 Valve Manifold, SMO 254 3 Way Manifold Valves, UNS S31254 Manifold Valves, 6MOLY SMO 254 5 Way Manifold Valves Suppliers, Alloy 254 2 Way Manifold Valve, DIN 1.4547 Manifold Valve, SMO 254 Instrument Manifold Valves Manufacturers in Mumbai, India.

Virgin engineers are the leading manufacturers, suppliers, and exporters of SMO 254 Manifold Valves that are manufactured using high quality of manifold valves as per the requirement and needs of the customer. It is one of the best components used in the industrial systems for controlling the fluid flow so as to regulate the pressure. On the other hand, these valves offer a variety of services as per the usage. There are different types of valves available and in few conditions, there are two or more valves required in that case SMO 254 Manifold Valves are used. The manifold equipment helps connect two and more valves of hydraulic systems to be connected to each other. The isolate or block valves can also be combined with single body configuration. Every valve has its separate opening and the main valve chamber or body is common for all. The manifold valves mainly include bleed, vent, ball and needle valves which results in saving the installation cost and space. There are several advantages offered by these valves and used in numerous applications that range from heavy industrial equipment to mobile machinery. They are fully customized in different shapes and sizes as required by the customers.

SMO 254 Hydraulic Manifold, SMO 254 Three Way T- Type Manifold Valves, SMO 254 Remote-Mount, Alloy 254 Bellows Sealed Manifolds, Stainless Steel SMO 254 H Series Manifold Valves, SMO 254 Block and Bleed Valves, SMO 254 R - Type Manifold Valve, SMO 254 Double Block Bleed Valves, SMO 254 Instrumentation Manifold Valves.

SMO 254 Valves Manifolds, SMO 254 2 Valve Manifold, SMO 254 Remote-Mount Manifold Valve, SMO 254 5 Valve Manifold, SMO 254 Direct-Mount Manifolds Exporters, SMO 254 3 Valve Manifold Supplier in Mumbai, India.

The valves are manufactured using high and excellent quality of raw material that is well inspected and tested by the quality inspection agencies. These valves do not get damaged at high temperature and pressure. The material is properly tested so that it can provide its best under the respective areas of working. In addition to it, national and global specifications are added to the material in order to make it a high-quality product.

Alloy 254 SMO is basically high molybdenum as well as nitrogen based super austenitic stainless steel having a lower amount of carbon content. The alloys exhibit excellent resistance to crevice corrosion, pitting and corrosion fatigue. It is substantially stronger than other grades and has high tensile strength. That is why; it is widely preferred by manufacturers for manufacturing manifold valves and other equipment. The alloy also has high ductility as well as impact strength.

These SMO 254 manifold valves when fully manufactured are sent to the testing process where qualified professionals test these valves under different situations and climatic conditions. The testing is mainly done keeping in mind the demand of customers as well as industrial norms. There are several tests done like pitting resistance test, third-party inspection, flaring test, flattening test, durability test, positive material identification test.

There are many more tests done like a destructive and non-destructive test, chemical composition analysis and hardness test. Once all the tests are done, these valves are sent for the packaging process where proper care is given for labeling. The labeling consists of information like manufacturers name, product name, size and more. After this, the SMO 254 manifold valves are packed with high quality of packaging material like wooden cases, pallets and cartons that help prevent rust and other damages.

Specification

ASTM

ASTM A276, A351, A494 / ASME SA276, SA351, SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | SIS | JIS |

| SMO 254 | S31254 | 1.4547 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 | 2378 |

| Grade | Ni | C | Mo | Mn | Si | f | Cu | S | P | Cr |

| SMO 254 | 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | - | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| Density | Melting Point | Yield Strength (0.2%Offset | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Products

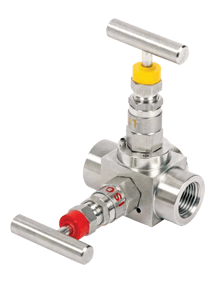

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

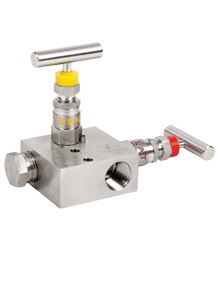

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

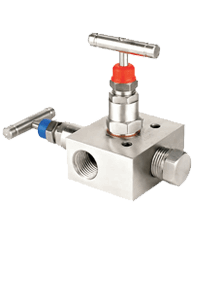

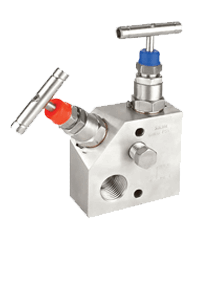

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

SMO 254 S31254 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on SMO 254 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

smo 254 manifold valves manufacturer in mumbai, smo 254 2 way manifold valve for pressure gauge, smo 254 manifold valve size, smo 254 types of manifold valves, smo 254 manifold valves types, smo 254 2 valve t type manifold valve, smo 254 5 valve remote mounted, smo 254 manifold valves distributors, smo 254 manifold 3 valves 2 ways, smo 254 manifold hydraulic valves, smo 254 3 valve direct mounted, smo 254 manifold valve dealers, smo 254 manifold mounted ball valves, smo 254 manifold valves manufacturers in india, smo 254 manifold valves price, smo 254 manifold valve application, smo 254 stainless steel manifold valves stockists, smo 254 manifold valves traders, buy high quality smo 254 manifold valves, smo 254 manifold valves stockholder, smo 254 3 way manifold price list.

© Copyright | Virgin Engineers 2021. All Right Reserved.