- Home

- Products

- Hot Dip Galvanised Instrument Air Header

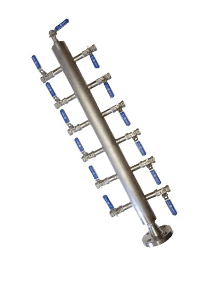

- Stainless Steel / Carbon / Alloy Steel Hot Dip Galvanised Instrument Air Header

Hot Dip Galvanised Instrument Air Header

SS Hot Dip Galvanised Instrument Air Header, Hot Dip Galvanised Carbon Steel Instrument Air Header, Stainless Steel Hot Dip Galvanised Industrial Instrument Air Header, Alloy Steel Hot Dip Galvanised Instrument Air Header Suppliers, Hot Dip Galvanised Steel Instrument Air Header Manufacturers in Mumbai, India.

Virgin Engineers Hot Dip galvanized Instrument Air header acts as the distribution manifolds that it’s providing the users with several connections choices for isolation manifolds. The industry as a reliable manufacturer, supplier and stockiest are offering this product at wider ranges of configurations that are based upon the needs of users like compression outlet, BSP, Butt-weld, etc. This product is the best alternative for the multiples of valves assemblies that normally functions from one origination point.

The industry as a supplier is also supplying the Stainless Steel Hot Dip galvanized Instrument Air header that includes the instrument valves like needle valves, coupling, and etc base upon client’s desires. The major point of making the air header is to offer customization to the greater possible level. The air header must essentially have the ability to suit the system with fullest perfections. A buyer can choose the header as per own needs that include, schedules, length, sizes, etc. Also, it is offered at custom made specifications according to the drawing provide for the custom needs.

Carbon Steel Hot Dip Galvanizing Steel Ped-Lock Air Headers, Hot Dip Galvanizing SS Instrument Air Header Exporters, Hot Dip Galvanizing Chromium Molybdenum KE Grey Air Header, Chrome Moly Hot Dip Galvanizing RSI Air Headers, Hot Dip Galvanizing Carbon Air Headers Supplier in Mumbai, India.

Hot Dip Galvanizing Steel Polished Air Header, Stainless Steel Hot Dip Galvanised HYPER VALVES 2" Air Header, Alloy Steel Hot Dip Galvanizing United Air Header, Hot Dip Galvanizing Carbon SMIPL Air Header, Hot Dip Galvanised Steel NE Air Headers, Hot Dip Galvanised CRMO Pneumatic Air Headers.

The manufacturing process in short-

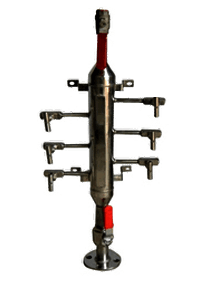

Instrument Air header is designed and fabricated from the pipe or bar stock that is customized based on the drawings of customers. The manufacturer is offering it in the various special coating in which hot-dip galvanizing is one. Also, this is manufactured by using various metals like stainless steel, Monel, high duty bronze, Hastelloy, etc.

The entire process of manufacturing is done under the strict guidance of professional experts that are having very good skills and experience of making the best possible quality of air header. The designing of this product is done by considering raw material quality standards and manufacturing norms. Also, the use of modern tools and advanced technology has helped the manufacturers in bringing out the commendable quality of the product.

What are the advantages of using an air header?

There are many good benefits associated with Carbon steel and Alloy Steel Hot Dip galvanized Instrument Air header that every air header is factory examined, available in a customized compact design. Also, the multiple valve outlets and inlets save the costs and it is available in varieties of end connections.

Documenting of the air header-

At the time of shipping of the product, the industry being reliable is considering offering the essential documents to the buyers. It is including fumigation certification, Commercial invoice, packaging list, raw material test report, material traceability report, guarantee letter, NABL approved lab test report, certificate of origin, etc. Also, the test certifications are also offered to the buyers like 100% radiography test report, MTC as per EN 10204/3.1B, raw material certificate, buyers report and third-party inspection report.

Inspection-

At the manufacturing unit the inspection on a regular basis is welcomed so that the entire production process of air header can be checked and well analyzed. The inspection is done by a third party inspection agency that is legally certified and is having proper knowledge of doing inspection based upon a few parameters.

Packaging-

To assure safer transiting of air header, proper packaging is done into plywood/carton cases and as per customer needs.

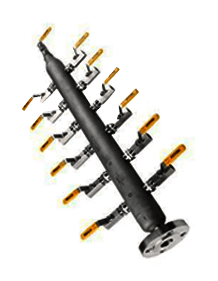

Specification

Types and Materials

Instrument Air Header, Carbon Steel, Stainless Steel, Alloy Steel

Port Size

1/4″ / 1/2″ NB SCH 40 / 80 Nipple Toe. Fitted on outlet ports 1/4″ / 1/2"

Working Pressure :

6000 psi [413 bar]

Size:

Inlet ½ "x Outlet½", Inlet ¾" x Outlet3/4"

Drain Plug

1/2″ SCH 40 / 80 Nipple TOE Fitted with SS Ball Valve & Drain

Outlet ports :

6way / 8way / 12 way / 16way (Staggering or straight, Single sided or Double sided)

Inlet :

DIN & ANSI 1/2″ / 1″ NB Flanged / Threaded Connections.

Main Pipe :

1″, 1-1/2″, 2″ NB SCH 40 / 80.

End Connections :

NPT, BSPT, SW

Temperature rating

PTFE 450 °[232 °c ]/Grafoil-700° F[371° C]

Products

Hot Dip Galvanised Ped-Lock Air Headers

Hot Dip Galvanised KE Grey Air Header

Hot Dip Galvanised RSI Air Headers

Hot Dip Galvanizing Steel Polished Air Header

Hot Dip Galvanised HYPER VALVES 2 Air Header

Hot Dip Galvanised SMIPL Air Header

Hot Dip Galvanised Pneumatic Air Headers

Hot Dip Galvanised Air Distribution Header

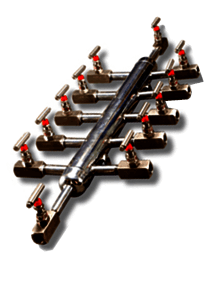

Quality Assurance

Hot Dip Galvanised Steel Instrument Air Header are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Hot Dip Galvanised Instrument Air Header are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

hot dip galvanised instrument air header size, hot dip galvanised steel inx polished air header size, hot dip galvanised stainless steel instrument air header, alloy steel hot dip galvanised ke grey air header, carbon steel hot dip galvanised ne air headers price, hot dip galvanised crmo instrument air header chemical composition, hot dip galvanised stainless steel hyper valves 2" air header types, hot dip galvanised Chromium Molybdenum pneumatic air headers dealers, chrome moly Hot Dip Galvanised ped-lock air headers, Hot Dip Galvanised steel instrument air header standards, stainless steel Hot Dip Galvanizing air distribution header india, Hot Dip Galvanizing steel smipl air header, stainless steel Hot Dip Galvanizing instrument air header mechanical priperties, buy high quality alloy steel Hot Dip Galvanizing instrument air header, Hot Dip Galvanised valtech air headers manufacturer in mumbai, Hot Dip Galvanizing crmo instrument air header distributors, Hot Dip Galvanised rsi air headers, Hot Dip Galvanizing instrument air header traders, Hot Dip Galvanizing instrument air header specification, hot dip galvanised instrument air header size, hot dip galvanised united air header, hot dip galvanizing steel instrument air header stockholder, hot dip galvanizing carbon ke grey air header stockists.

© Copyright | Virgin Engineers 2021. All Right Reserved.