- Home

- Products

- Forged Valves

- Inconel 600 Forged Valves

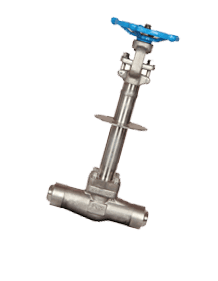

Inconel 600 Forged Valves

Inconel 600 Forged Valves, Inconel Alloy 600 Forged Valves, Alloy 600 Forged Valves, Grade 600 Inconel Forged Valves Suppliers, UNS N06600 Forged Valves, DIN 2.4816 Forged Valves, Alloy 600 Forged Valves Manufacturers in Mumbai, India.

Virgin engineers are leading manufacturer as well as the supplier of the excellent quality of Inconel 600 Forged Steel Valves. These valves are designed according to the international and national product quality standards thus ensuring high quality as well as durability. We are offering the comprehensive ranges of this product and it varies in standards, rating, sizes, types and end connections. To the universal and domestic buyers, this product is made under the set industrial norms.

Inconel 600 Forged Gate Valve, Alloy 600 Forged Globe Valves, Inconel 600 Forged Check Valves, Inconel® 600 Forged Y-PATTERN Valves, Inconel 600 Forged Valves Exporters, Alloy 600 Forged Integral Flanged End Valves, Grade 600 Inconel Forged Valves, Inconel® 600 Forged Valve, Alloy 600 Forged Valves Supplier in Mumbai, India.

Inconel 600 Flanged End Valve, Inconel Alloy 600 Bellow Sealed Valve, Inconel 600 Cryogenic Valve, Inconel Alloy 600 Forged Bolted Bonnet Valves, Alloy 600 Welded Bonnet Forged Valves.

For manufacturing process of the Inconel 600 forged steel valves we are making use of high quality of alloy. The Inconel 600 alloy that they are using is well examined and approved to be used easily. At the time of product fabrication, the utilization of sophisticated technology and modern tools have proved to be a lot helpful in making the superior quality of valves.

We are designing this product same as per set manufacturing techniques and national/international product quality standards. Moreover, the professional experts are there that are assigned with the task of guiding the workers to design the product in such a way that assures fines surface finishes and perfect dimensional accuracy.

Effectiveness in the manufacturing of Inconel 600 forged steel valves has to lead it to bring out many good features due to which it is widely used in many applications. The resistance to oxidation, dimensional accuracy, fine surface finishes, general corrosion resistance, high tensile strength, mechanical strength, easy to use at high temperature, the anti-corrosive body has made it a perfect choice.

Alloy details-Inconel 600 alloy is the chromium and nickel-based alloy that is used for those applications that are demanding corrosion and heat resistance. This alloy easily stands out in industrial applications due to high-temperature oxidation resistance and remains greatly oxidation resistant. Alloy 600 develops the tight adherent oxide scale that resists spalling even at the severe thermal cycling conditions. This nickel alloy is having very good temperature strength and retains the ductility after it gets exposed to the long services. Additionally, the alloy is having very good high-temperature strength, welded, machined and formed readily. All those properties have made this alloy to be used widely in many industrial applications.

Material testing: The testing is conducted at the manufacturing plant is to check how good is the product quality. Intergranular corrosion test, positive material identification test, hardness test, pitting resistance, mechanical test, chemical test, etc are performed on it.

Documenting of this product: The documents of the product are provided to the buyers like heat treatment chart, quality assurance plan, packaging list, commercial invoice, guarantee letter, raw material test report, material traceability report, NABL approved laboratory test report. The test certifications are also provided to the buyers that include mill test certifications in accordance with EN 10204/3.1B, 100% radiography test report, third-party test report, raw material certificate, and buyers report.

Packaging: The Inconel 600 forged steel valves are packed into wooden cases and in carton boxes for assuring harmless shipping of the ordered product to the buyers. Moreover, packing is covered with thin film of plastic that adds prevention from contamination.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| Alloy 600 | N06600 | 2.4816 | NCF 600 | NC15FE11M | NA 13 | МНЖМц 28-2,5-1,5 | NiCr15Fe |

| Grade | Ni | Cr | Fe | C | Mn | S | Si | Cu |

| Inconel 600 | 72.0 min | 14.0 – 17.0 | 6.0 – 10.0 | 0.15 max | 1.0 max | 0.015 max | 0.5 max | 0.5 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1370-1425 ℃ | 550 min. | 240 min. | 30 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Inconel N06600 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 600 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 600 forged valves standards, inconel 600 Forged valves, alloy 600 forged gate valves, inconel 600 forged globe valves, parker inconel forged valves grade 600, alloy 600 bolted bonnet forged valves size, alloy 600 forged valves pressure sealed bonnet, inconel® 600 forged valves types, alloy 600 forged valves welded bonnet design, alloy 600 forged seal welded valves , inconel 600 socket welded forged valves, alloy 600 forged valves price, alloy 600 flanged end globe valves stockists , inconel 600 flanged end gate valves dealers, inconel® 600 flanged end check valves manufacturer in mumbai, alloy 600 pressure seal bonnet forged valves india, inconel 600 forged pressure seal bonnet valves distributors, inconel alloy 600 bolted bonnet forged gate valves, inconel alloy 600 welded bonnet globe valves stockholder, buy high quality inconel® 600 forged valves, inconel alloy 600 swagelok forged valves, inconel alloy 600 parker forged valves, inconel® alloy 600 screwed forged valves traders.

© Copyright | Virgin Engineers 2021. All Right Reserved.