- Home

- Products

- Forged Valves

- Incoloy 800 / 800H / 800HT Forged Valves

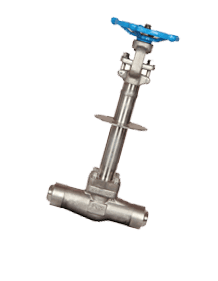

Incoloy 800 / 800H / 800HT Forged Valves

Incoloy 800 Forged Valves, Incoloy Alloy 800H Forged Valves, Alloy 800 / 800H / 800HT Forged Valves, Grade 800 Incoloy Forged Valves Suppliers, UNS N08800 Forged Valves, DIN 1.4876 Forged Valves, Alloy 800/800H Forged Valves Manufacturers in Mumbai, India.

Virgin engineers are engaged in providing top quality Incoloy 800 / 800H / 800HT Forged Steel Valves at best affordable rates. We provide these forged steel valves in various specifications, designations, standards, dimensions and more. Our offered forges steel valves are widely available in different industrial applications such as petrochemical, thermal processing, natural gas processing, and other sectors. We are the superior distributor of high quality components to withstand the at most fluctuating temperatures. Our offered products meet the most industrial norms and other specifications as well as a cross-reference to the various global standards.

Once you reach us, you will get the Incoloy forged steel valves in the top standard designations at most reasonable rates. Additionally, we also offer high grade collection of forged steel valves in non-standard dimensions; customers can get for their specific applications.

Incoloy 800/800H//800HT Forged Gate Valve, Alloy 800 Forged Globe Valves, Incoloy 800H Forged Check Valves, Inconel® 800HT Forged Y-PATTERN Valves, Incoloy 800 Forged Valves Exporters, Alloy 800H/800HT Forged Integral Flanged End Valves, Grade 800 Incoloy Forged Valves, Inconel® 800H Forged Valve, Alloy 800HT Forged Valves Supplier in Mumbai, India.

Incoloy 800 Flanged End Valve, Incoloy Alloy 800H Bellow Sealed Valve, Incoloy 800HT Cryogenic Valve, Incoloy Alloy 800 Forged Bolted Bonnet Valves, Alloy 800/800H/800HT Welded Bonnet Forged Valves.

What are Incoloy 800 / 800H / 800HT Forged Steel Valves?

These valves are manufactured by closed die forging operation that involves shaping billets while heating they remain in solid form. The forging dies are used to press the heated billets to build required shapes and dimensions. The forging operation is performed in most temperatures depends on the end application.

The forging operation provides valves great strength which makes them ideal for high pressure and high temperatures applications. Apart from high strength, the grain structure of valves is also refined. Thus, this increases the overall impact strength. The forging operation can remove chances of defects such as shrinkage, porosity, and cracks.

Moreover, forged steel valves can generate with less wall thickness. These forged steel valves offer great resistance to corrosion and abrasion. This offers great resistance to pitting and crevice corrosion in higher temperatures.

Quality assurance program runs effectively in our organization, these measures maintain the highest level of quality with zero losses. The quality is inspected by our trained professionals who have great experience in this field. Our quality measures are well defined and thoroughly implemented in each production sector. The different destructive analysis is performed in each lot that assures the reliability of products.

Following are the test- traveling valve test, backseat test, closure test, pitting corrosion test, functional tests, thermal performance test, radiographic test, and shell leakage test. Other tests are valve seat leakage test, pneumatic test, hydrostatic test, cryogenic testing, burst tests and fire safe tests, drill stem test, IGC test, ultrasonic test, etc.

To ensure our brand quality, we provide some credentials and documentation reports to the customers. those are national board approval lab (NBAL) test report, QAP, fumigation certificates, MTC report as per EN 10204 3.1 or 3.2 raw material test report, mill test report, etc. Moreover customers can demand other credentials as per their requirements.

For damage-free shipping, we use industry standard packaging methods such as wooden crates, plywood cases, cartons, pallets, and other customized packing. Furthermore, each packing is wrapped in contamination-free wrapping.

Place your order for Incoloy 800 / 800H / 800HT Forged Steel Valves at virgin engineers in different forms and shapes.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | - | X8NiCrAlTi32-21 | XH32T |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Alloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Alloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Alloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 800/800H/800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Incoloy N08800 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Incoloy 800 / 800H / 800HT Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

incoloy 800 forged valves standards, incoloy 800 / 800h / 800ht Forged valves, alloy 800h forged gate valves, incoloy 800ht forged globe valves, parker incoloy forged valves grade 800h, alloy 800h bolted bonnet forged valves size, alloy 800ht forged valves pressure sealed bonnet, incoloy® 800h forged valves types, alloy 800ht forged valves welded bonnet design, alloy 800h forged seal welded valves , incoloy 800ht socket welded forged valves, alloy 800 forged valves price, alloy 800h flanged end globe valves stockists , incoloy 800h/800ht flanged end gate valves dealers, incoloy® 800h flanged end check valves manufacturer in mumbai, alloy 800ht pressure seal bonnet forged valves india, incoloy 800/800h forged pressure seal bonnet valves distributors, incoloy alloy 800/800ht bolted bonnet forged gate valves, incoloy alloy 800 welded bonnet globe valves stockholder, buy high quality incoloy® 800 forged valves, incoloy alloy 800/800h/800ht swagelok forged valves, incoloy alloy 800 parker forged valves, incoloy® alloy 800 screwed forged valves traders.

© Copyright | Virgin Engineers 2021. All Right Reserved.