- Home

- Products

- High Pressure Pipe Fittings

- Inconel Alloy High Pressure Pipe Fittings

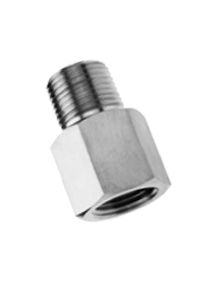

Inconel High Pressure Pipe Fittings

Inconel Industrial High Pressure Pipe Fittings, Incoloy® Alloy Pressure Pipe Fittings Suppliers, High Pressure Inconel Pipe Fittings, Inconel High Pressure Pipe Fittings Manufacturers in Mumbai, India.

Virgin engineers are a leading name in the field of manufacturing, exporting, supplying the qualitative range of Inconel High Pressure Pipe Fittings. We manufacture a wide range of high pressure pipe fittings in ferrous and non-ferrous grades. We are famous among national and international customers because of action to provide qualified products. These high pressure pipe fittings are famous due to its good resistance to corrosion, pressure and high temperatures. These pipe fittings are manufactured under the strict guidance and conditions by our expert team. All important quality standards are followed in our production unit to make sure that final products are extremely efficient and durable.

Inconel Alloy High Pressure Pipe Fittings offer gleaming creep and stress rupture properties that makes these pressure pipe fittings viable option for application in the elevated temperatures. It has great resistance to oxidation and other reducing zones make it an appropriate option for severe applications. These pressure pipe fittings have resistance to scaling in the elevated temperatures. It has the ability to form a protective layer in addition with aluminium that allows it to perform in intermitting temperatures up to 2300 deg F with minimum erosion.

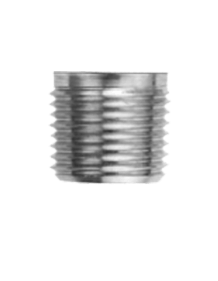

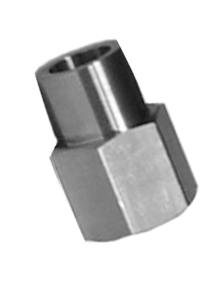

Inconel Hex Reducing Nipple, Inconel Alloy Hex Long Nipple Exporters, Incoloy Alloy Reducing Adapter, Incoloy Reducing Bushing, Inconel Alloy Hex Coupling Supplier in Mumbai, India.

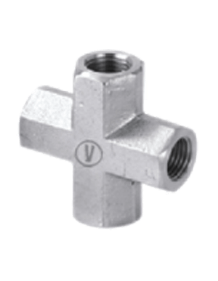

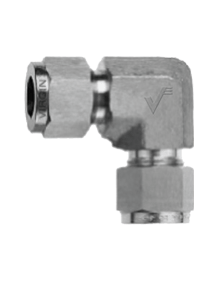

Inconel Alloy Male and Female Elbow, Inconel Elbow Reducing Street, Inconel Allen SAE Plug, Inconel Gauge Adapter, Inconel® Alloy Union Cross, Inconel Female Connector, Inconel Union Elbow.

Grade details:

It is nickel and chromium alloy designed for use in higher temperature surveillance. It has a higher amount of chromium content with a nominal amount of aluminium compared to its standard grade. It forms a solid oxide layer in elevated temperatures that offers outstanding resistance to oxidation up to 2200 deg F under the cyclic conditions. It has a higher resistance to stress corrosion cracking. These pressure pipe fittings are not recommended for severe environments containing sulfur content. These high pressure pipe fittings are not extensively used in heat treating conditions and also in process heat streams.

The presence of chromium and nickel content not only deliver the superior corrosion resistance to higher temperatures, however, but it also provides resistance to wet corrosive media. This grade has an equal level of corrosion as its previous version. Inconel High Pressure Pipe Fittings can be exposed in the critical chemical zones such as nitric acid, sodium hydroxide solutions, low concentrations of phosphoric acid, and seawater. Because of higher nickel composition, these high pressure pipe fittings offer brilliant resistance to chloride stress corrosion cracking in mild environments.

However, Inconel alloy is not heat treatable; it is hardened by cold working methods. The annealing process is performed after the cold working process in order to receive higher ductility. After the metal treatment process, these are processed for the heat treatment process. The softening of grade is starts from 871 deg C temperature and grain growth starts from 1010 deg C.

Testing of the plates-

We perform different tests on a manufactured range of high pressure pipe fittings for quality assurance. Those tests are a hardness test, PMI test, compression test, mechanical test, IGC test, and pitting corrosion test.

Inconel High Pressure Pipe Fittings are available in various designations, standards, specifications and custom dimensions one can avail from us as per needs and requirements.

Specification

Types

High Pressure Pipe Fittings

End Connections :

NPT, BSP, & BSPT.

Size Range

1/16” to 2”

Inconel High Pressure Pipe Fittings

Products

Close Nipple

Hex Nipple

Hex Reducing Nipple

Hex Long Nipple

Reducing Adapter

Reducing Bushing

Hex Coupling

Hex Reducing Coupling

Elbow Female

Elbow Reducing Street

Male Elbow

45° Elbow Female

45° Elbow Street

Tee Female

Tee Street

Tee Branch

Tee Male

Cross Female

Union Ball Joint

Hex Female Cap

Hex Male Plug

Allen Plug

Hex SAE Plug

Allen SAE Plug

SAE Adapter

Hex Pipe Plug

Gauge Adapter

Male Connector

Female Elbow

Union Cross

Female Connector – FF

Union

Union Elbow

Male Adaptor NPT

BSPT Coupling

Quality Assurance

Inconel High Pressure Pipe Fittings are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel Alloy High Pressure Pipe Fittings are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel high pressure pipe fittings standards, inconel alloy high pressure pipe fittings, inconel alloy high pressure pipe fittings chemical composition, incoloy close nipple, inconel® alloy hex nipple, inconel hex reducing nipple, inconel® hex long nipple, inconel adapter & reducing adapter size, inconel alloy reducing bushing types, inconel hex coupling, inconel hex reducing coupling size, inconel alloy elbow female, inconel elbow street price, inconel alloy elbow reducing street stockists, incoloy® male elbow dealers, inconel 45° elbow female manufacturer in mumbai, inconel alloy 45° elbow street india, inconel tee female/street/branch/male distributors, inconel alloy cross female, inconel alloy high pressure pipe fittings stockholder, buy high quality incoloy alloy hex female cap, inconel high pressure pipe fittings traders, inconel hex male plug and sae plug, inconel allen plug, inconel alloy sae adapter, inconel® hex pipe plug mechanical priperties, inconel alloy gauge adapter size, inconel male connector specification.

© Copyright | Virgin Engineers 2021. All Right Reserved.