- Home

- Products

- Valves

- Manifold Valves

- Duplex Steel S31803 / S32205 Manifold Valves

Duplex Steel S31803 / S32205 Manifold Valves

Duplex Steel S31803 Manifold Valves, Duplex S32205 2 Way Manifold Valve, Duplex Steel S31803 3 Way Manifold Valves, Duplex Steel S31803 / S32205 Valve Manifold, S31803 Duplex Manifold Valves, DIN 1.4462 Manifold Valve, SAF 2205 Instrument Manifold Valves Suppliers, Duplex S32205 5 Way Manifold Valves Manufacturers in Mumbai, India.

Today Duplex Steel S31803 / S32205 Manifold valves are manufactured and offered by numbers of industries and Virgin Engineers are one among those. We are a manufacturer making it by using the very good quality of raw substances. The use of better quality of alloy makes the product greatly stronger and other industrialists can buy and use those at the high-temperature atmosphere. Our company is dealing globally with the wider ranges of product. The product variety is differentiated on the basis of different types, sizes, standards, dimensions, end connections, pressure rating, etc. our company is also offering the same at custom-built specifications same as per the needs.

Duplex Steel S31803 Direct-Mount Manifolds, Duplex Stainless Steel S32205 2 Valve Manifold, Duplex Steel S31803/S32205 Valves Manifolds, Duplex S31803 Remote-Mount Manifold Exporters, Duplex S32205 3 Valve Manifold, SAF 2205 Manifold Valves, Duplex Steel S31803 / S32205 5 Valve Manifold Supplier in Mumbai, India.

Duplex Steel S31803/S32205 Block and Bleed Valves, Duplex 2205 V/ VB and VL series Manifolds, Duplex S31803 Remote-Mount, Duplex Stainless Steel S32205 H Series Manifold Valves, Duplex Steel S31803 Bellows Sealed Manifolds, Duplex Steel S31803 Double Block Bleed Valves, Duplex S32205 Hydraulic Manifold, Duplex S32205 Three Way T- Type Manifold Valves, Duplex S31803 / S32205 Instrumentation Manifold Valves, SAF 2205 R - Type Manifold Valve.

2205 is one of the mostly used duplex steel grades. Today it has found many applications because of high tensile strength and very good corrosion resistant feature. The composition of standards duplex S31803 is refined by the steel suppliers and that has resulted in the restricted composition as UNS S32205 was endorsed. Duplex S32205 provides very good corrosion resistance ability but for Duplex S31803 that is currently developed is also complying with S32205. But S32205 is not right for use at the high temperature above 300 Deg C because it is suffering from the precipitation of brittle small constituents and not below -50 Deg C due to ductile to brittle transitions.

The production factor of the Duplex Steel S31803 / S32205 Manifold valves, it is executed by the utilization of very good quality of alloy. The raw materials used are 100% pure and is well tested so that no ineffective quality of manifold valves is produced. The designing and fabrication of the same are done by using refined technology and modern tools under the tight supervision of a professional team. The entire ranges of valves are developed according to the national and international product quality standards and set production norms.

The material testing is playing an important role in the manufacturing unit as it helps us to check the quality of the product. The testing done in the testing facility is like positive material identification test, hardness test, intergranular corrosion test, flattening test, flaring test, chemical test, mechanical test, non-destructive test, and destructive tests.

The test certifications to the buyers are provided is including manufacturer test certifications as per EN 10204/3.1B, third-party test report, raw material certificate, and buyers report. The documents offered to the buyers are heat treatment chart, raw material test report, guarantee letter, material traceability report, packaging list, quality assurance plan, NABL approved lab report, chemical/mechanical reports, etc.

In order to supply every single piece of produced ranges of Duplex Steel S31803 / S32205 Manifold valves without getting damages, it is packed carefully. As the product during the time of shipment needs to pass through numbers of channels to reach its endpoint, the chances of getting harm become a little bit high. So it is packed into wooden cases and carton boxes for harmless shipping.

Specification

ASTM

ASME / ASTM A995/A182/A351/A890

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Duplex Steel S31803 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| Duplex Steel S32205 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Products

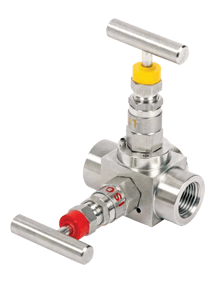

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

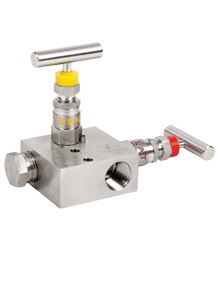

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

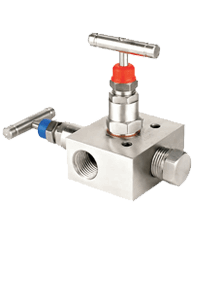

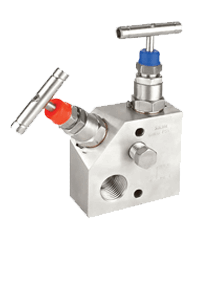

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Duplex Steel S31803 / S32205 manifold valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Duplex Stainless Steel S31803 / S32205 manifold valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

duplex steel s31803 3 way manifold price list, duplex steel s32205 manifold 3 valves 2 ways, duplex s31803/s32205 manifold valve size, duplex steel s32205 manifold valves manufacturer in mumbai, duplex s31803 manifold valves price, s31803/s32205 duplex steel manifold valve application, duplex steel s31803 3 valve direct mounted, duplex steel s32205 manifold hydraulic valves, duplex stainless steel s31803 / s32205 manifold valves stockholder, buy high quality duplex steel s32205 manifold valves, duplex s31803 2 way manifold valve for pressure gauge, saf 2205 manifold mounted ball valves, duplex s32205 manifold valves manufacturers in india, duplex steel s31803 5 valve remote mounted, duplex stainless s31803/s32205 manifold valves traders, duplex steel s31803 / s32205 manifold valve dealers, duplex steel s31803 manifold valves distributors, duplex s32205 manifold valves stockists, saf 2205 2 valve t type manifold valve, s31803 duplex steel types of manifold valves, duplex steel s32205 manifold valves types.

© Copyright | Virgin Engineers 2021. All Right Reserved.