- Home

- Products

- Forged Steel Valves

- SMO 254 Forged Steel Valves

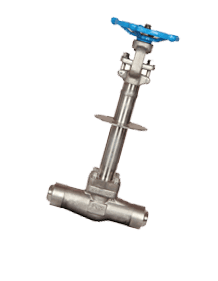

SMO 254 Forged Steel Valves

6Moly Forged Valves Suppliers, DIN 1.4547 Forged Steel Valves, 254 SMO Forged Steel Valves, UNS S31254 Forged Steel Valves, Stainless Steel SMO 254 Forged Steel Valves, SMO Stainless Steel 254 Forged Valves, Alloy 254 Forged Steel Valves Manufacturers in Mumbai, India.

Virgin engineers have rich experience in the field of manufacturing stainless steel products. Here we are dealing with kinds of ferrous and non-ferrous grades one of them is SMO 254 Forged Steel Valves. It is high in demand because of its prominent features such as workability, formability, resistibility, sturdy design, robust construction, uniform structure and more. Our management team has decades of experience in the field of the metal processing industry. Our company experienced consistent growth reflecting customer satisfaction with the products and service offered.

We supply client’s sizes from all over the world. We are making these forged steel valves in all types of standards, specifications, designations, non-standard dimensions and shapes requested by the customers.

SMO® 254 Forged Steel Gate Valve, SMO 254 Forged Steel Valves, SMO 254 Forged Steel Integral Flanged End Valves, Alloy 254 Forged Steel Y-PATTERN Valves Exporters, 6Moly Forged Valve, Grade 254 SMO® Forged Valves, SMO Stainless Steel 254 Forged Globe Valves, SMO 254 Forged Steel Check Valves Supplier in Mumbai, India.

SMO® 254 Cryogenic Valve, SMO 254 Forged Valves, Stainless Steel SMO 254 Welded Bonnet Forged Valves, SMO 254 Forged Steel Bolted Bonnet Valves, 6Mo Flanged End Valve, SMO 254 Bellow Sealed Valve.

SMO 254 Forged Steel Valves provide crevice and pitting corrosion resistance that is superior to traditional stainless steel grade in all most corrosive environments. These forged steel valves have also great corrosion and abrasion fatigue properties as well as lower thermal expansion and good thermal conductivity. SMO 254 has the duplex microstructure that enhances the stress corrosion cracking resistance property. For instance, it performs well in the chloride stress corrosion environments.

The SMO 254 grade posses twice yield strength than its standard version. Thus, this permits it to the user in low weight application that reduces its cost. Mainly, these forged steel valves are suitable for application in the down to higher temperatures between -50 deg F to 600 deg F. this alloy is combined with higher strength and oxidation resistance to corrosion fatigue.

We are committed to raise the standards of our products and services to offer customer satisfaction through excellence in quality. Our every employee is dedicated towards the motto and measure of quality to ensure the production of superior quality products, on-time delivery, leading prices, prominent packaging, sales services and more. From received crude materials to the final inspection of finished products, we do everything to ensure our customers will get only the very best quality of products.

Of course, all manufactured forged steel valves are processed from destructive and non-destructive testing. Those are valve seat leakage test, backseat test, low/ high temperature testing, closure test, shell leakage test, pneumatic test, hydrostatic test, cryogenic testing, pitting corrosion test, and radiographic test. Other tests are burst tests, fire safe tests, functional tests, relief test, IGC test, transfer valve test, drill stem test, traveling valve test, etc

We provide some reports and documentation to the customers as a quality proof. The reports include a specification guide, fumigation certificates, MTC report, raw material test report, mill test report, and quality assurance plan. Other reports are Commercial invoice, stamping details, national board approval lab (NBAL) test report, etc.

Packaging: We use only standard and tested packing methods for delivery of forged steel valves. Those include wooden cases, cartons, pallets and plywood cases with a thin film of plastic that adds prevention from moisture. Customized packing options are also provided to customers as per their suitability.

Without thinking much place orders now to buy SMO 254 Forged Steel Valves at reasonable rates.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | SIS | AFNOR | EN |

| SMO 254 | 1.4547 | S31254 | 2378 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |

| Grade | C | Mn | Si | S | Cu | Ni | Cr | N | Mo | P |

| SMO 254 | 0.02 max | 1 max | 0.8 max | 0.01 max | 0.5 – 1 | 17.5 – 18.5 | 19.5 – 20.5 | 0.18 - 0.22 | 6 – 6.5 | 0.03 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1320-1390°C | 650 | 300 | 35 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel S31254 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on SMO 254 Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

buy high quality 6moly forged steel valves, parker stainless steel forged valves grade 254, smo 254 welded bonnet globe valves stockholder, alloy 254 forged steel valves standards, smo 254 forged steel valves price, 6moly Forged valves, smo 254 pressure seal bonnet forged valves india, 6moly flanged end gate valves dealers, alloy 254 flanged end check valves manufacturer in mumbai, smo 254 flanged end globe valves stockists, smo 254 bolted bonnet forged gate valves, smo 254 forged seal welded valves, alloy 254 forged steel globe valves, alloy 254 socket welded forged steel valves, alloy 254 forged steel pressure seal bonnet valves distributors, smo 254 forged steel valves pressure sealed bonnet, smo 254 swagelok forged steel valves, smo 254 parker forged steel valves, smo 254 forged gate valves, alloy 254 forged steel valves types, 6mo screwed forged steel valves traders, smo 254 forged steel valves welded bonnet design, smo 254 bolted bonnet forged steel valves size.

© Copyright | Virgin Engineers 2021. All Right Reserved.