- Home

- Products

- Forged Valves

- Alloy 20 Forged Valves

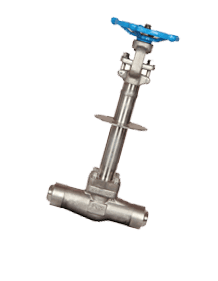

Alloy 20 Forged Valves

Alloy 20 Forged Valves, Carpenter 20 Forged Valves, Carpenter 20Cb-3 Forged Valves Suppliers, 20 Alloy Forged Valves, UNS N08020 Forged Valves, DIN 2.4660 Forged Valves, Alloy 20 Forged Valves Manufacturers in Mumbai, India.

Virgin engineers are the leading and renowned manufacturer of different types of steel valves that are used for regulating, controlling and directing the flow of liquids. However, Alloy 20 Forged Valves are widely preferred by industrialists due to its amazing properties and features that it offers. The valves are known best while providing proper control over the flow of liquids in industrial applications. Being one of the reputed companies in India, we are aimed to provide our products not only in the domestic country but to the worldwide customers.

The Forged Valves are made into different shapes, sizes and forms as demanded and required by the customers for their applications. The Forged Valves are made by the qualified professionals and using upgraded technology and latest machines. The valves are forged in such a way that it can be easily used in high temperature and pressure.

Carpenter 20Cb-3® Forged Steel Gate Valve, Alloy 20 Forged Steel Y-PATTERN Valves Exporters, Alloy 20 Forged Steel Integral Flanged End Valves, Carpenter 20Cb-3 Forged Valve, Alloy 20 Forged Globe Valves, Alloy 20 Forged Valves, Incoloy® Alloy 20 Forged Valves, Alloy 20 Forged Steel Check Valves Supplier in Mumbai, India.

Alloy 20 Forged Valves, Carpenter 20Cb-3® Cryogenic Valve, Alloy 20 Forged Steel Bolted Bonnet Valves, Carpenter 20 Flanged End Valve, Alloy 20 Welded Bonnet Forged Valves, Alloy 20 Bellow Sealed Valve.

Alloy 20 is also known as UNS N08020 which is a standard specification for this alloy. It is an austenitic and nickel-iron as well as chromium based superalloy having some amount of molybdenum and copper that offers resistance to the antagonistic environment. The alloy is also stabilized with the columbium that minimized carbide precipitation at the time of welding. The alloy 20 mainly appears between stainless steel as well as nickel-based alloy categories as it consists features of both.

The alloy is designed for maximum resistance to acid attack and exhibit superior resistance to corrosion cracking in the sulfuric acid and has general corrosion resistance.

Well, if we talk about the manufacturing process these Alloy 20 Forged Valves are manufactured under the strict guidance of experts having years of experience in the industrial sector. They make use of premium and top-notch quality of raw material for manufacturing these valves. Every material is well inspected and tested so that it does not create any damage or defect once these valves are manufactured. After the testing process, the material is sent for the manufacturing process where the latest technology and machines are used for making the material into a usable form for manufacturing Forged Valves.

There are a lot of features these valves exhibit like high strength, excellent controlling and directing the feature, require low maintenance cost, highly durable and easy to install. Along with this, these valves have the feature of bearing high temperature and pressure without getting damaged.

Packaging: There are several tests performed by the manufacturers so that they can check whether the manufactured Forged Valves are of high quality or not. Therefore, there are several tests done like flaring test, flattening test, hardness test, third-party inspection, visual inspection, radiography test, IGC test, and ultrasonic test. For all these tests, manufacturers offer various tests certificates proving that the manufactured product is of high quality.

At last, these Alloy 20 Forged Valves are packed in high quality of packaging material like wooden cases, boxes, pallets or poly bags that help avoid damage and rust.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy 20 | 2.4660 | N08020 |

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi - 35,000, MPa - 241 | 30 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Alloy N08020 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Alloy 20 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

alloy 20 forged globe valves, buy high quality carpenter 20cb-3 Forged Valves, carpenter 20 screwed Forged Valves traders, alloy 20 forged gate valves, alloy 20 pressure seal bonnet forged valves india, alloy 20 Forged Valves price, carpenter 20cb-3® flanged end gate valves dealers, parker grade alloy 20 forged valves, alloy 20 Forged Valves welded bonnet design, alloy 20 welded bonnet globe valves stockholder, alloy 20 Forged Valves pressure sealed bonnet, alloy 20 flanged end check valves manufacturer in mumbai, alloy 20 bolted bonnet Forged Valves size, carpenter 20 Forged valves, alloy 20 forged seal welded valves, alloy 20 forged pressure seal bonnet valves distributors, alloy 20 socket welded Forged Valves, alloy 20 swagelok Forged Valves, alloy 20 Forged Valves standards, alloy 20 Forged Valves types, alloy 20 bolted bonnet forged gate valves, alloy 20 flanged end globe valves stockists, alloy 20 parker forged valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.