- Home

- Products

- Instrumentation Tube Fittings

- SMO 254 Instrumentation Tube Fittings

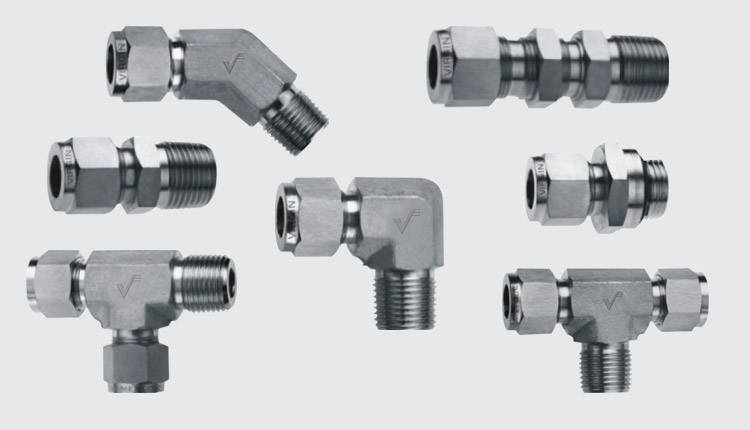

SMO 254 Instrumentation Tube Fittings

SMO 254 Compression Tube Fittings, DIN 1.4547 Instrumentation Tube Fittings, SMO 254 Instrumentation Fittings Suppliers, Alloy 254 Double Ferrule Tube Fittings, SMO 254 Tube Fittings, 6MOLY Single Ferrule Fittings, UNS S31254 Instrumentation Tube Fittings, SMO 254 Ferrule Fittings Manufacturers in Mumbai, India.

Virgin Engineers is esteem and authorized venture that is pretty much engaged in catering to a wide variety of SMO 254 Instrumentation Tube Fittings to their domestic as well as global clients. We designed our products from superior quality of raw material that we acquire from the authorized merchants of the market. Our main motive is to offer a quality range product and services to our esteem customers thus we offer our products in customized design, shapes, length, size, grade, and dimensions that suits their requirements and demands. We have acknowledged professionals and employees that are been aware of the objectives of the company and efficiently work within their own discipline as to obtain the global standard product. Furthermore, we make use the latest inspection tools and state of art machinery to meet all the requisites and needs.

SMO 254 Male Connector, SMO 254 Bulk Head Male Connector, SMO 254 Male Elbow, SMO 254 Male Branch Tee, SMO 254 Male Run Tee Exporters, S31254 Female Connector, SMO 254 Bulk Head Female Connector, SMO 254 Female Elbow Supplier in Mumbai, India.

SMO 254 Bulk Head Union, SMO 254 Front Ferrule, SMO 254 Female Run Tee, SMO 254 Female Branch Tee, SMO 254 Reducer Union, SMO 254 Union Cross, SMO 254 Reducer Port Connector – RPC, SMO 6MOLY NPT Male Adapters, Alloy 6MOLY BSPT Couplings, SMO 254 BSPP Plugs.

SMO 254 Instrumentation Tube Fittings is the higher strength austenitic stainless steel alloy fittings that constitute a high level of nickel, nitrogen, chromium, and molybdenum along with low carbon content. These alloys of instrumentation tube fittings are significantly stronger than the other general austenitic grades. These tubes fittings are suitable in high chloride surroundings such as sea and brackish water. The addition of chromium, nickel and nitrogen and molybdenum enhances superior resistance to stress corrosion cracking, crevice and pitting corrosion at soaring temperatures. The low carbon content reduces the risk of carbide precipitation at the time of heat treatment.

The tube fittings are superior to conventional stainless steel mainly in acids containing halides furthermore these exhibits good resistance to uniform corrosion also. The hot working of these tube fittings can be performed at 982 -1149 degree F while the cold worked is done through all traditional methods. The annealing is performed at 1149-1204 degree C that can be followed through water quenching. The machinability of these fittings is tough but using overpowered machines, ample lubrication, sharp tools, and slow speed leads to offer good machining outcome. In addition without any subsequent heat treatment process these fittings ensure good weldability.

At our manufacturing unit, several testing and quality programs are performed on the various level of production to achieve the highest level of quality and working ability of the product. These tests are like a mechanical test, hardness test, pitting resistance test, macro/micro test, flattening test, chemical analysis. Other more tests are PMI test, radiography test, ultrasonic test, IGC test, and tensile strength test.

In order to prove the quality of the product, we offer reliable test certificate to the buyers as per their esteem requirements. These certificates are like raw material test certificate, third-party test report and 100% radiography test reports.

To dispatch the product with great safety and prevention we adhere to pack the products in high-quality packaging material that helps to avoid any type of damage and scratch during shipping. Thus we pack the products in wooden cases, wooden cartons, wooden crates, and wooden pallets and in wooden boxes. At last, these get properly marked with logo, size; lot no, length and specifications.

Specification

Size Range

1/16” 1/2” & 1.5MM to 38.1MM

| STANDARD | UNS | WNR. | AFNOR | SIS | JIS |

| SMO 254 | S31254 | 1.4547 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 | 2378 |

| Grade | Ni | C | Mo | Mn | Si | f | Cu | S | P | Cr |

| SMO 254 | 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | - | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| Density | Melting Point | Yield Strength (0.2%Offset | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Products

Male Connector NPT-M

Male Connector BSP-M

Bulk Head Male Connector BMC

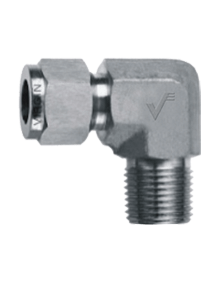

Male Elbow ME

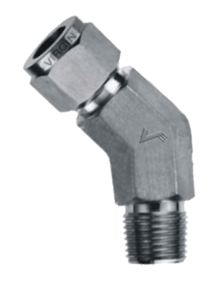

45° Male Elbow 45ME

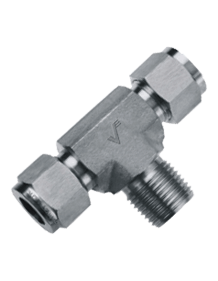

Male Branch Tee MBT

Male Run Tee MRT

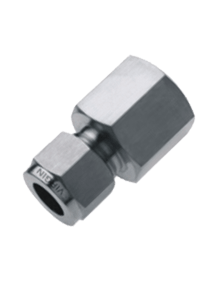

Female Connector FC

Bulk Head Female Connector BFC

Female Elbow FE

Female Run Tee FRT

Female Branch Tee FBT

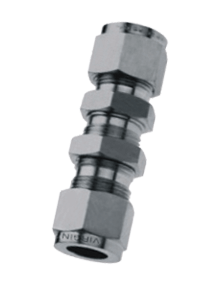

Union U

Reducer Union RU

Bulk Head Union BU

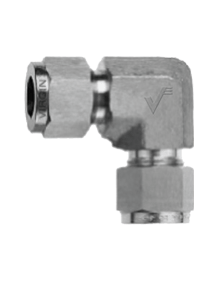

Union Elbow UE

Union Tee UT

Union Cross UC

Reducer R

Bulk Head Reducer BR

Port Connector PC

Male Adapter MA

Female Adapter FA

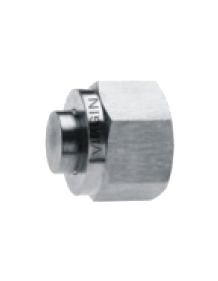

Cap TC

Plug (Port Ends) Tp

Tube Socket Weld Union TSWU

Male Pipe Weld Connector MPWC

Tube Socket Weld Elbow TSWE

Male Pipe Weld Elbow MPWE

Back Ferrule BF

Front Ferrule FF

Popular Searches

smo 254 instrumentation tube fittings price, smo 254 twin ferrule fittings distributors, smo 254 instrument fitting standards, smo 254 tube fittings stockists, smo 254 instrument tube size, buy high quality smo 254 instrument tube fittings, smo 254 instrument fitting size, smo 254 compression fittings dealers, smo 254 parker tubing, smo 254 instrumentation valves and fittings india, smo 254 parker tubing fittings, smo 254 duolok tube fittings, smo 254 instrumentation fittings stockholder, smo 254 instrumentation tube fittings manufacturer in mumbai, smo 254 tylok instrumentation fittings traders, smo 254 instrument fittings types, smo 254 instrument fitting standards, smo 254 swagelok fittings, smo 254 instrument fittings swagelok, smo 254 ferrule fittings.

© Copyright | Virgin Engineers 2021. All Right Reserved.