- Home

- Products

- Condensate Pots

- Hastelloy C22 Condensate Pots

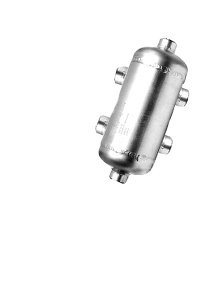

Hastelloy C22 Condensate Pots

DIN 2.4602 Condensate Pots, Grade C22 Hastelloy Condensate Pots Suppliers, C22 Steel Condensate Pots, Hastelloy C22 Condensate Pots, Hastelloy Condensate Pots, UNS N06022 Condensate Pots, Alloy C22 Seal Pots Manufacturers in Mumbai, India.

Condensate pots are the components that are mainly used to hold and catch condensate whereas foreign materials. Therefore these prevent from damage occurred to the metering system. The function of these pots is to let a solution seal in between the flowing gases like steam and instruments. These pots maintain the fluid level constant in the impulse tubes. However, these are mainly designed to maintain the pressures with a gas holder.

The installation of these pots is done either in horizontal or vertical lines in the middle of main or secondary instruments. These act as a barrier to the line fluid that allows direct sensing of the flow situations.

There is the huge assortment of condensate pots are available in the market in a diverse range, types and in grades to buy the best quality of condensate Hastelloy C22 Condensate Pots is best one among all the grades. These ranges of condensate pots are highly demanded and admired by the customers due to its superior features and attributes.

Hastelloy Alloy C22 Condensate Pot Seal Pot, Alloy C22 2 Ports Condensate Pots, Grade C22 Hastelloy Condensate Seal Pots, Alloy C22 Condensation Pots, Hastelloy C22 Seal Pots, Hastelloy Alloy C22 Seal Pots Exporters, Hastelloy Condensate Pots, Hastelloy C22 DRIP Pots, Hastelloy C22 Condensate Pots Supplier in Mumbai, India.

Alloy C22 Condensate Pots, Hastelloy C22 Condensate Seal Chambers, Hastelloy Alloy C22 Condensate Chamber, Hastelloy C22 Condensate Seal Pots, Hastelloy Alloy C22 Seal Pots, Hastelloy C22 Condensate Pots.

Hastelloy C22 Condensate Pots are designed from the austenitic chromium-molybdenum-nickel alloy adding with tungsten content. These are the versatile pots that enhance superior resistance to stress corrosion cracking, crevice and pitting corrosion in harsh climatic circumstances. These alloys of pots are highly resistant to aggressive environments. The high chromium content delivers superior resistance to various oxidizing media while the nickel alloy possesses superior resistance to oxidizing aqueous media that includes chlorides, formic and acetic acids, and wet chlorines. Furthermore, the nickel alloy excellently resists the formation of grain boundary precipitates in the weld heat affected zone.

The forging of these alloys of pots is performed at 1750-2050 degree F pursued by rapid cooling. Furthermore, the annealing must be executed at a temperature of 2020-2150 degree F followed through rapid quench. Even more, the welding of these pots is done by the shielded metal arc, gas metal arc, and gas tungsten process.

Virgin Engineers is a highly acclaimed and esteemed firm that provides qualitative range of Hastelloy C22 Condensate Pots to their esteem clients. Being a reputed organization we are fully involved in fabricating, distributing and supplying good quality of the product. Therefore the manufacturing of these pots is effectively done with superior quality of raw material that is sourced out from the reputable merchants of the market. We have a team of qualified professional experts and dedicated working staff that are actively immersed in manufacturing good quality of the product. On the other hand, we properly utilized the latest technology and advanced machinery that assures to result in the excellent quality of product fabrication.

However, we supply a national and international standard product in a diverse range, thickness, length, shapes, size in accordance with the customer’s requirements and demands of the customers.

To make sure about the quality of the product we performed various testing and inspection process at our manufacturing end. These tests are like intergranular corrosion test, mechanical test, pitting resistance test, PMI test, hydrostatic test, ultrasonic test. Furthermore, the test is impact test, hardness test, chemical analysis, tensile strength test and many more.

Specification

Size

2", 3", 4", 6" & Larger size

End Connections

NPT

Pipe Schedule

40, 80, 160, XXS Seamless Steel

Length

8”, 10” & 12" & Larger size

Working Pressure

6000 PSIG(41.34 MPa)

Thread Connections

NPT as per ANSI B1.20.1,Socket weld as per ANSI B16.11, Butt weld as per ANSI B16.9

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| C22 | 2.4602 | N06022 | NW 6022 | – | NiCr21Mo14W | – |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

Products

Condensate Pots 2 Ports

Condensate Pots 3 Ports Type 1

Condensate Pots 3 Ports Type 2

Condensate Pots 4 Ports Type 1

Condensate Pots 4 Ports Type 2

Condensate Pots 4 Ports Type 3

Condensate Pots 6 Ports

Condensate Seal Pots

Quality Assurance

Hastelloy N06022 Condensate Pots are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Hastelloy C22 Condensate Pots are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

hastelloy c22 condensate pot 3 ports type 3 india, alloy c22 condensate pot 3 ports type 1 size, hastelloy c22 seal chambers, alloy c22 parker condensate pots, parker hastelloy condensate pots grade c22, alloy c22 condensate pots cp1 series, hastelloy c22 seal pots stockists, hastelloy alloy c22 condensing pots stockholder, hastelloy c22 condensate pot 4 ports type 1 manufacturer in mumbai, hastelloy c22 condensate pot 4 ports type 1, hastelloy c22 air header, hastelloy alloy c22 fabricated condensate pots size, nickel alloy c22 condensate pots price, buy high quality hastelloy c22 condensate pots, alloy c22 condensing chamber, hastelloy alloy c22 condensate pots 2 ports, hastelloy c22 condensate pot 6 ports distributors, hastelloy c22 condensate seal pots traders, hastelloy c22 condensate pots standards, hastelloy c22 condensate pot 3 ports type 2 dealers, hastelloy c22 condensate pots types, alloy c22 swagelok condensate pots, hastelloy c22 seal pots.

© Copyright | Virgin Engineers 2021. All Right Reserved.