- Home

- Products

- Needle & Gauge Valves

- Chromium Molybdenum Needle & Gauge Valves

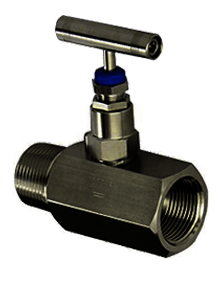

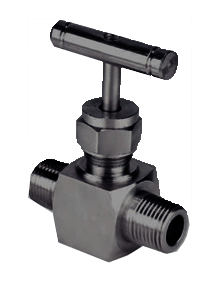

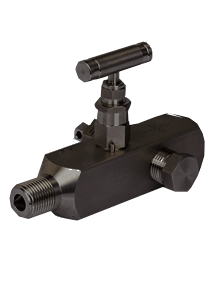

Alloy Steel Needle & Gauge Valves

CrMo Gauge Bleed Needle Valves Suppliers, Cr-Mo Needle & Gauge Valves, Alloy Steel Gauge Valves, Alloy Steel Industrial Needle & Gauge Valve, Chrome Moly Needle / Gauge Valves, Chromium molybdenum Needle and Gauge Valves Manufacturers in Mumbai, India.

Virgin engineers offered Alloy steel Needle & Gauge Valves are of very good quality that the buyers expect from the industry. We as a customer oriented is offering the product to the buyers at different specifications for the fulfillment of all applications desirability. We as a manufacturer, supplier, exporter, and stockholder are offering the product at customized specifications as per the demands the buyers as per the drawings they have provided to the buyers. A buyer seeking to buy it can avail at a different design, sizes, connection, flow pattern, end connections, working pressure, temperature rating, etc.

The offered ranges of Chromium Molybdenum Needle & Gauge Valves manufacturing is done by using the very good quality of alloy that is sourced from the reliable market mills. To offer the commendable quality of same to the buyers, the product is fabricated by using the latest technology and modern tools. There at our manufacturing unit the availability of professional experts has proved to be a lot helpful as their effective guidance to the workers has led to the excellent quality of product development. Additionally, the development of the same is conducted as per set manufacturing norms and raw material quality standards.

Chromium molybdenum Parker Needle Valve, Cr-Mo Screwed End Needle Valve, CrMo Hydraulic Needle Valve, Alloy Steel Gauge Vent Valves Exporters, Chromium molybdenum Multiport Gauge Valves Supplier in Mumbai, India.

Chrome Moly Gauge and Needle Valves, Alloy Steel Needle / Gauge Valves, Alloy Steel Needle Valve, Alloy Steel Forged Body Gauge Valve, Cr-Mo Autoclave Needle Valve, Chrome Moly Integral Bonnet Needle Valve, CrMo Gauge Valve.

Features of the product-

Many good properties are found in the product due to which it has become high in demand. Some of them are like compact design, low operating torques, every single piece of product is well tested, dust cap provided, available in ranges of material, high-pressure rating available till 15000 PSI and verify end connections are there like BSPT, NPT, etc.

Alloy information for you-

Alloy steel is considered to be the alloy that is having ranges of elements in total amount in between 1.0% - 50-% by the weight for improving the mechanical properties. Alloy steel is broken down into two types like high alloy steel and low steel alloy. Alloy steel is actually the standard term that refers to the steel with other alloying element that are added to the carbon. Some of the common alloyants are like manganese, boron, vanadium, molybdenum, silicon, chromium and nickel. Also, the less common alloyants are there like zirconium, aluminium, zinc, cobalt, tin, cerium, copper, tungsten, and niobium, etc.

Testing of the material-

To supplying the high quality of product to the buyers, the testing is essentially conducted. The tests done are like positive material identification test, chemical test, mechanical test, pitting resistance test, hardness test, intergranular corrosion test, visual inspection, etc.

Test certifications provided-

Manufacturer test certifications as per EN 10204/3.1B, 100% radiography test report, third-party inspection report, buyers report are the important test certifications offered to the buyers.

Documents offered-

There are few important documents offered to the buyers are like packaging list, commercial invoice, raw material test report, material traceability report, guarantee letter, NABL approved lab test report.

Packaging-

The packaging of CrMo Needle & Gauge Valves is done carefully for guaranteeing harmless delivering. The packaging is done in wooden cases, carton boxes and wrapped individually in environmental poly bags.

Specification

Types

Needle Valve, Gauge Valves

Size

1/8 to 1”, Custom Sizes are also available on request

Design

Forged Body with Inline / Straight or Angle Pattern, Integral Bonnet Design

End

Male and Female BSPT, NPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Female to Female, Male to Female

Connection

Female to Female, Male to Female

Working Pressure

Up to 6000 PSIG, Higher Pressure valves are also available that can handle higher pressure.

Temperature Rating

PTFE 450F, (232C) / Grafoil 700 F (371C)

Stem

Vee Steam is standard for pressure tightness even at elevated temperatures. Regulating Stem and Soft-Seat Stem are optional

Testing

100% Factory Tested

Packing

PTFE, Grafoil

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Needle Valve – O.D.

Needle Valve – Angle

Gauge Valve – Multiport

Gauge Valve – Block & Bleed

Quality Assurance

Alloy Steel Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Chromium Molybdenum Needle and Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

chromium molybdenum gauge valve, alloy steel 3 way needle valve dealers, alloy steel forged body gauge valve types, alloy steel hydraulic needle valve, chrome moly block & bleed gauge valves, chromium molybdenum autoclave needle valve manufacturer in mumbai, crmo gauge vent valves, alloy steel needle & gauge valve standards, chrome moly screwed end needle valve stockists, chromium molybdenum gauge valve, cr-mo multiport gauge valves, chrome moly gauge bleed needle valves, chrome moly needle valve distributors, chromium molybdenum integral bonnet needle valve price, alloy steel parker needle valve india, gauge & needle alloy steel valve stockholder, buy high quality alloy steel needle and gauge valve, alloy steel high pressure gauge valve size, alloy steel gauge/needle valve traders, alloy steel needle valve standards, alloy steel bonnet needle valves size.

© Copyright | Virgin Engineers 2021. All Right Reserved.