- Home

- Products

- Needle & Gauge Valves

- Nickel 200 Needle & Gauge Valves

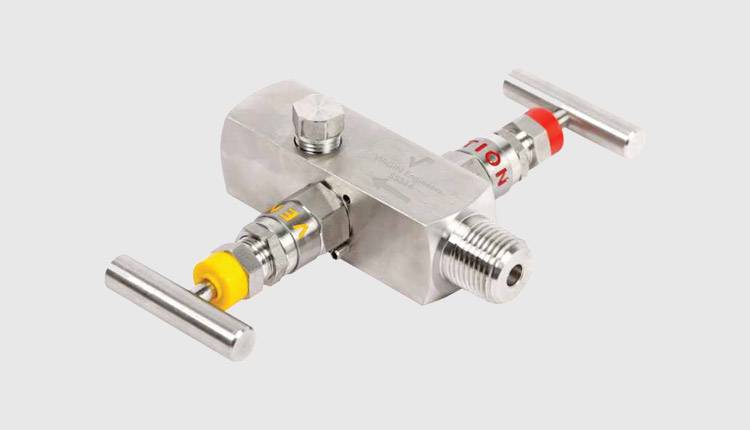

Nickel Alloy 200 Needle & Gauge Valves

Nickel Alloy 200 Hydraulic Needle Valve, Nickel® 200 Multiport Gauge Valves, Grade 200 Nickel Alloy Gauge Vent Valves Exporters, UNS N02200 Needle & Gauge Valve, DIN 2.4066 Needle and Gauge Valves, Ni 200 Screwed End Needle Valve, Nickel 200 Parker Needle Valve Manufacturer in Mumbai, India.

Virgin engineers are fully involved in manufacturing, exporting, supplying the excellent quality of Nickel 200 Needle & gauge valves to the buyers. The industry is offering the wider range of these grade valves to the buyers all across the globe. This industry is today high in demand with traditional industries as well as the clientele indulge into the modern megatrends. When comes to buying the needle and gauge, Virgin engineers is the name that is entered into the mind. The industry is offering very good quality of same to the buyers in different specifications that are varying in standards, end connection, pressure rating, types, temperature rating, working pressure, sizes, etc. it is supplied to the buyers at market leading rates.

Ni Alloy 200 Screwed End Needle Valve, Alloy 200 Nickel Multiport Gauge Valves, Nickel 200 Gauge Vent Valves Exporters, JIS NW 2200 Nickel Parker Needle Valve, Nickel Alloy 200 Hydraulic Needle Valve Supplier in Mumbai, India.

Alloy 200 Needle / Gauge Valves, Nickel Alloy 200 Integral Bonnet Needle Valve, Nickel Alloy 200 Gauge Valve, Nickel 200 Needle Valve, Nickel 200 Forged Body Gauge Valve, Ni 200 Autoclave Needle Valve Needle and Gauge Valves.

Alloy overview-

Nickel 200 is a nickel alloy with very good mechanical properties over the ranges of temperature and is also greatly resistant to several corrosive in hydroxides. The excellent resistant to corrosion at alkalis and acid and usefulness at reducing conditions are making it a perfect choice. The very good resistant to caustic alkalis are also making it good to use. At the alkaline, acid and neutral salt solution the material is showing very good resistant but in case of oxidizing salt solution, severe attacks might take place.

It is resistant to all dry gases at the room temperatures and also at dry chlorine and at the temperature ranging 550 Deg C the hydrogen chloride might be used. It is resistant to mineral acid that varies as per temperature and concentrations and whether solutions aren’t aerated or not, the corrosion resistant is very good at de-aerated acid.

Qualities of the product-

The properties like high tensile strength, high yielding strength, anti-corrosive body, withstand high temperature, long-lastingness, reliable to use, etc is making it the ideal choice. Also, it is resistance to all localized attacks like general corrosion, pitting, oxidation, crevice corrosion, stress corrosion cracking, etc is making the product good to use.

Development of the product-

The development of the product is done by using the superior quality of alloy in compliance with advanced technology and modern tools. The manufacturing of it is done under the strict guidance of professional experts that guides the workers in an effective way to design the product so that perfect dimensional accuracy and smooth surface finishes can be guaranteed. These needle and gauge valves are designed as per the set manufacturing norms and national and international product quality standards.

Testing-

At the manufacturing industry, the testing of every single piece of produced Nickel 200 Needle & gauge valves are done to check the product quality. The tests done are like PMI test, IGC test, hardness test, pitting resistance, chemical test, mechanical test, etc.

Documents offered-

The documents offered are like fumigation certificate, commercial invoice, packaging list, heat treatment chart, guarantee letter, raw material test report, material traceability report, NABL approved lab test report.

Test certifications-

Few test certifications like MTC as per EN 10204/3.14, 100% radiography test report, third-party test report, raw material certificate; etc is offered to the buyers.

Specification

Types

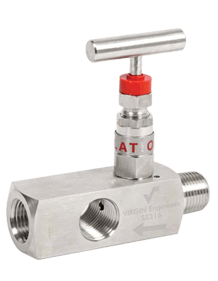

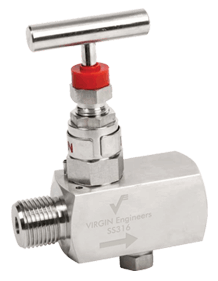

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Nickel N02200 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Nickel 200 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

nickel Alloy 200 gauge vent valves, nickel® 200 bonnet needle valves size, nickel Alloy 200 needle & gauge valve standards, nickel 200 parker needle valve india, Alloy 200 nickel gauge valve, alloy 200 forged body gauge valve types, nickel Alloy 200 needle valve distributors, nickel 200 screwed end needle valve stockists, nickel Alloy 200 3 way needle valve dealers, 200 Nickel alloy high pressure gauge valve size, nickel alloy 200 gauge/needle valve traders. nickel Alloy 200 condensate pots manufacturer supplier 200 hydraulic needle valve, nickel 200 needle shutoff and regulating valves standards, nickel 200 integral bonnet needle valve price, nickel alloy multiport gauge valves grade 200, buy high quality nickel alloy 200 needle and gauge valve, nickel 200 block & bleed gauge valves, nickel® 200 gauge bleed needle valves, nickel 200 gauge & needle valve stockholder, Nickel alloy 200 autoclave needle valve manufacturer in mumbai, nickel 200 gauge valve.

© Copyright | Virgin Engineers 2021. All Right Reserved.