- Home

- Products

- Forged Valves

- Hastelloy C22 Forged Valves

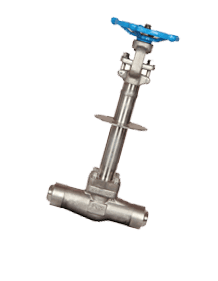

Hastelloy C22 Forged Valves

UNS N06022 Forged Valves, DIN 2.4602 Forged Valves, Hastelloy C22 Forged Valves, Alloy c22 Forged Valves Manufacturers , Alloy c22 Forged Valves, Grade c22 Hastelloy Forged Valves Suppliers, Hastelloy Alloy c22 Forged Valves Manufacturers in Mumbai, India.

As much admired organization in the market, we as Virgin Engineers are quite engaged in proposing the collection of Hastelloy C22 Forged Steel Valves. . We are global suppliers, exporter, manufacturer and stockiest providing products to domestic and international customer’s at most reasonable rates. With the huge experience and knowledge in this field, we are quite recognized in providing high class range of Hastelloy valves. In view of having high grade quality, reasonable rates, great performance, we offer a qualitative range of products in the market.

Grade C22 Hastelloy Forged Valves, Hastelloy® C22 Forged Valve, Alloy C22 Forged Valves Supplier, Hastelloy C22 Forged Check Valves, Hastelloy C22 Forged Gate Valve, Alloy C22 Forged Globe Valves, Hastelloy C22 Forged Valves Exporters, Hastelloy® C22 Forged Y-PATTERN Valves, Alloy C22 Forged Integral Flanged End Valves in Supplier Mumbai, India.

Hastelloy Alloy C22 Bellow Sealed Valve, Hastelloy Alloy C22 Forged Bolted Bonnet Valves, Hastelloy C22 Cryogenic Valve, Alloy C22 Welded Bonnet Forged Valves, Hastelloy C22 Flanged End Valve.

Grade description:

It is employed in applications that require excellent resistance to natural corrosion, pitting corrosion, crevice corrosion, stress corrosion cracking, and intergranular corrosion. It is resistive to reducing and oxidizing conditions and sufficient aqueous corrosion. These forged steel valves are used in water treatment plants. The material of Hastelloy grade is examined to ensure its resistance ability. However, with the limited composition of alloy provide improves workability. Hastelloy C22 Forged Steel Valves are selected over 19 different alloy valves due to its extensive resistance to corrosion.

Grade resistance ability:

These valves offer superior resistance to oxidizing and reducing media ideal for streamline process. Because of its large flexibility, it can be induced in the severe conditions that are encountered in the multifunctional industries. These valves offer intense resistance to various chemical processing streams such as oxidizers that includes ferric, cupric chloride, hot solutions containing organic, inorganic compounds, formic, acetic acids, acetic anhydride, etc. It has higher resistance that also resists the formation of grain precipitates in the weld affected zone. Thus, this makes it best for use in the chemical processing process in the welded zone.

The wrought Hastelloy is made in the heat processed solution until it is reached on the desired properties. These forged steel valves are processed from heat at 2050 deg F- 1121 deg F temperature and also it is quickly quenched. The forged steel valves are hot or cold forged must be processed solution heat treatment before fabrication. The thermal stability of alloy is set into an oxidizing sulfuric acid process solution. This grade will suffer from unwanted attacks on the severe base metal, heat affected area, and weld metals. It is found that only one-third of the heated grade is corroded, however, C 22 grade is toughly corroded in this condition.

These forged steel valves are chosen for application in the bleach water conditions. It offers prolonged performance without corroding. It offers better resistance ability than its original versions. We also perform different types of tests on a manufactured range of valves for quality assurance. The tests include Cryogenic testing, low temperature testing, high temperature, burst tests, valve seat leakage test, backseat test, traveling valve test, and hydrostatic test. Other tests are closure test, shell leakage test, pneumatic test, fire safe tests, relief test, transfer valve test, drill stem test, intergranular corrosion test, ultrasonic test, radiographic test, pitting corrosion test, and so on.

Third parties perform the last stage testing that assures complete reliability of products. To make a purchase of Hastelloy C22 Forged Steel Valves get it from the virgin engineers at cost effective rate.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | UNS | WNR. | AFNOR | EN | JIS |

| Hastelloy C22 | N06022 | 2.4602 | - | NiCr21Mo14W | NW 6022 |

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

| Hastelloy C22 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000, MPa – 690 | Psi – 45000, MPa – 310 | 45 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Hastelloy N06022 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Hastelloy C22 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

hastelloy® c22 forged valves types, alloy c22 bolted bonnet forged valves size, hastelloy® c22 flanged end check valves manufacturer in mumbai, alloy c22 forged seal welded valves, alloy c22 forged valves welded bonnet design, alloy c22 forged valves price, hastelloy alloy c22 swagelok forged valves, alloy c22 pressure seal bonnet forged valves india, hastelloy c22 forged pressure seal bonnet valves distributors, hastelloy alloy c22 bolted bonnet forged gate valves, alloy c22 forged valves pressure sealed bonnet, hastelloy alloy c22 welded bonnet globe valves stockholder, hastelloy c22 socket welded forged valves, alloy c22 forged gate valves, hastelloy c22 flanged end gate valves dealers, buy high quality hastelloy® c22 forged valves, parker hastelloy forged valves grade c22, hastelloy alloy c22 parker forged valves, alloy c22 flanged end globe valves stockists, hastelloy c22 forged valves standards, hastelloy c22 forged globe valves, hastelloy® alloy c22 screwed forged valves traders, hastelloy c22 forged valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.