- Home

- Products

- Forged Valves

- Hastelloy c276 Forged Valves

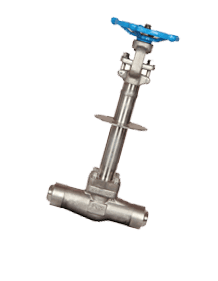

Hastelloy c276 Forged Valves

Grade c276 Hastelloy Forged Valves Suppliers, UNS N10276 Forged Valves, DIN 2.4819 Forged Valves, Hastelloy Alloy c276 Forged Valves, Alloy c276 Forged Valves, Alloy c276 Forged Valves Manufacturers , Hastelloy c276 Forged Valves Manufacturers in Mumbai, India.

Virgin Engineers are acknowledged organization in the market that is engaged in offering their services to their buyers across the world. We are established long years back with a vision of offering the right quality of product to the buyers. The Buyers from across the world prefer Virgin Engineers when looking to buy valves since we offer unique features on our products. The unique traits include high end finishing; accurate dimensions, sleek design and great durability of the product are some of the features. Other than this, we use raw material in the manufacturing which are bought from reliable market vendors. The trained professionals are entirely checking on the quality of the products at every stage of its manufacturing.

In order to increase the efficiency of the products, they use high tech modern machines and inventories in the manufacturing process. Being one of the reputed exporters is majorly concerned about the quality of the valves. And thus, we use good packaging methods which help them to avoid any kind of damage and other severe impurities.

Grade c276 Hastelloy Forged Valves, Alloy c276 Forged Globe Valves, Hastelloy® c276 Forged Y-PATTERN Valves, Hastelloy® c276 Forged Valve, Hastelloy c276 Forged Valves Exporters, Alloy c276 Forged Valves Supplier, Hastelloy c276 Forged Gate Valve, Alloy c276 Forged Integral Flanged End Valves, Hastelloy c276 Forged Check Valves in Supplier Mumbai, India.

Hastelloy c276 Cryogenic Valve, Alloy c276 Welded Bonnet Forged Valves, Hastelloy c276 Flanged End Valve, Hastelloy Alloy c276 Forged Bolted Bonnet Valves, Hastelloy Alloy c276 Bellow Sealed Valve.

Know about the grade used in fabricating Forged valves:

Since the Forged Steel valves are fabricated using various forging methods which involves the shaping and molding of the alloy being used. So in order to use them in severe conditions, we manufacture these valves using Hastelloy grade. The grade widely used in the manufacturing is Hastelloy C276.

Hastelloy C276 is also known as Alloy C276 which is a super alloy of nickel chromium molybdenum based which offers excellent strength and fabricability to the products. The addition of tungsten in the grade offers outstanding resistance to corrosion, great pitting resistance to chloride ion solutions in wide range of severe environments. Also, the presence of high quantity of nickel and molybdenum makes the alloy highly useful in the environment where there is a high corrosion and other oxidization environment. The C276 grade offers resistance to oxidizing media and crevice corrosion resistance in reducing environments.

The low carbon content of the grade easily minimizes the carbide precipitation when welding is performed in order to maintain “as-welded” structure in the corrosion environment. This nickel based alloy is highly resistive to the formation of grain boundary which precipitated in the high heat affected zone. Hence, the Hastelloy c276 Forged Steel Valvesare used in various industries across the globe.

Some of the relevant material tests performed:

We perform various quality tests on Hastelloy C276 Forged Steel Valves in order to ensure its strict quality and efficiency. The tests includes mechanical tests, pitting resistance tests, positive material identification tests, flaring tests, flattening tests, micro and macro tests, bend tests and destructive and non-destructive tests are some of the essential tests performed.

What are the packaging methods used?

We in order to preserve the high quality of the Hastelloy C276 Forged Steel Valves until the destination, they use efficient packaging methods. The valves are packed in large wooden cases, crates or boxes which are free from fumigation and other sort of impurities. Also, we offer shipping documents to their products.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

| Hastelloy C276 | N10276 | 2.4819 | - | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

| Hastelloy C276 | Balance | 0.010 max | 15–17 | 1.0 max | 0.08 max | 4–7 | 0.04 max | 0.03 max | 2.5 max | 14.5–16.5 | 3–4.5 | 0.35 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000, MPa – 790 | Psi – 52,000, MPa – 355 | 40 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Hastelloy N10276 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Hastelloy c276 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

hastelloy® c276 forged valves types, alloy c276 bolted bonnet forged valves size, hastelloy® c276 flanged end check valves manufacturer in mumbai, alloy c276 forged seal welded valves, alloy c276 forged valves welded bonnet design, alloy c276 forged valves price, hastelloy alloy c276 swagelok forged valves, alloy c276 pressure seal bonnet forged valves india, hastelloy c276 forged pressure seal bonnet valves distributors, hastelloy alloy c276 bolted bonnet forged gate valves, alloy c276 forged valves pressure sealed bonnet, hastelloy alloy c276 welded bonnet globe valves stockholder, hastelloy c276 socket welded forged valves, alloy c276 forged gate valves, hastelloy c276 flanged end gate valves dealers, buy high quality hastelloy® c276 forged valves, parker hastelloy forged valves grade c276, hastelloy alloy c276 parker forged valves, alloy c276 flanged end globe valves stockists, hastelloy c276 forged valves standards, hastelloy c276 forged globe valves, hastelloy® alloy c276 screwed forged valves traders, hastelloy c276 forged valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.