- Home

- Products

- Pipes / Tubes

- Monel 400 Pipes and Tubes

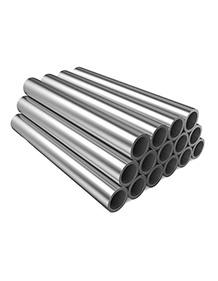

Monel Alloy 400 Pipes and Tubes

Monel Alloy 400 Tubing, Grade 400 Monel Seamless Pipes, ASTM B165 Monel Alloy 400 Tube Suppliers, UNS N04400 Pipes and Tubes, Monel Alloy 400 Pipes, Monel 400 Tube, DIN 2.4360 Pipes and Tubes, Monel 400 Pipes, ASTM B730 Monel 400 Welded Tube Manufacturers in Mumbai, India.

Virgin Engineers is a renowned Monel 400 pipes and tubes manufacturer, supplier, and stockist in Mumbai, India. The nickel-copper alloy Monel 400, also known as UNS N04400, is renowned for its remarkable durability, high tensile strength, and resistance to corrosion. Given their resistance to acidic, alkaline, and salty conditions, these pipes and tubes are widely used in various sectors, including power production, chemical processing, oil and gas, and maritime engineering. For applications requiring exceptional mechanical strength, thermal stability, and stress corrosion resistance, Monel 400 pipes—whether seamless or welded—are ideal.

ASTM B165 Monel Alloy 400 Seamless Pipes Dealer, Alloy 400 Piping Exporters in India, Monel Alloy 400 Seamless Tube, Monel Alloy 400 ERW Pipes, Monel 400 Welded Pipes, Monel Alloy 400 Pipe and Tube Supplier in Mumbai, India.

Monel Alloy 400 Square Tubes, Alloy 400 Pipes & Tubes, Grade 400 Monel Alloy Coiled Tubing, Monel Alloy 400 Threaded Pipes and Tubes Stockist, Monel Alloy 400 Round Pipes.

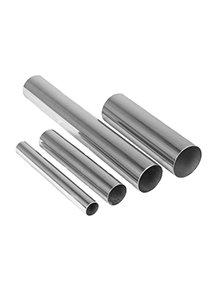

With trace amounts of carbon and silicon, Monel 400 pipes and tubes are composed of nickel (63% min), copper (28%–34%), iron (2.5% max), and manganese (2% max). This composition provides high endurance in harsh environments, remarkable strength, and resistance to pitting and crevice corrosion. Our Monel 400 tubes and pipes are made to meet international quality standards. They are made to DIN 2.4360 and EN standards, as well as international standards like ASTM B165/ASME SB165 for Monel seamless pipes and ASTM B725/ASME SB725 for Monel welded pipes. High-pressure pipe systems, offshore platforms, heat exchangers, and condensers frequently use these tubes—applications where durability and dependability are crucial.

We produce premium ASTM B725 Monel 400 pipes and tubes designed for demanding industrial uses. We offer them in SCH 5S, SCH 10S, SCH 40S, and SCH 80S to meet various operational requirements. Our Monel 400 pipes and tubes provide exceptional strength and longevity thanks to stringent quality control, accurate measurements, and exquisite finishing. They are appropriate for various industries since they are available in thicknesses ranging from 0.5 mm to 20 mm and diameters ranging from 6.35 mm to 219 mm.

Virgin Engineers, your go-to source for quality ASME SB725 Monel 400 pipes and tubes, has years of experience in the alloy sector and guarantees dependability, toughness, and superior performance in many applications. For specialized solutions and affordable prices, get in touch with us right now!

Specification

ASTM

ASTM B165, B725, B730, DIN, ASTM, BS and all International Standards.

Type

Seamless, ERW, Welded, Fabricated.

Thickness

0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm

Pipe Size / Tube Size

1/2" to 16"NB / 1/8" to 30"NB

ERW Pipe Size

1/2" to 24"NB

Other

Length - Single Random, Double Random and Cut

Lenght.

End - Plain End, Beveled End, Threaded etc.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28 – 34 | 2.50 max | 63.00 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Products

Seamless Pipes

Welded Pipes

Seamless Tubes

Welded Tubes

ERW Pipes

ERW Tubes

Round Pipes & Tubes

Square Pipes & Tubes

Rectangular Pipes & Tubes

Threaded Pipes & Tubes

Quality Assurance

Monel N04400 Pipes and Tubes are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Monel 400 Pipe & Tubes are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

400 seamless pipe manufacturer, 400 monel tubing suppliers, b165 400 monel alloy pipe, astm b165 400 pipes price in india, monel 400 pipe price, 400 seamless monel pipes, b165 tp 400 precision monel tubing suppliers, jindal monel alloy 400 pipes price list, monel alloy 400 seamless pipe sizes, monel alloy 400 pipe schedule chart, monel 400 coil tube in india, b165 tp400 seamless pipes, 400 seamless pipes for high pressure, schedule 40 monel 400 pipe, 400 monel tubing price in mumbai india, 400 alloy coil tubing, b725 400 welded monel pipes, large diameter steel pipe manufacturers in india, monel 400 mechanical tubing, prime quality 400 monel seamless pipes, schedule 10 monel 400 pipe, monel tube manufacturers in mumbai, monel 400 schedule 40 pipe, 400 monel tubing sizes, 400 monel pipe specifications, monel 400 tubing suppliers in mumbai india, 400 monel pipe price list, monel tp 400 sanitary tubing, monel 400 pressure pipe, alloy 400 tubing, erw monel 400 pipe.

© Copyright | Virgin Engineers 2021. All Right Reserved.