- Home

- Products

- Forged Steel Valves

- Stainless Steel 316L Forged Steel Valves

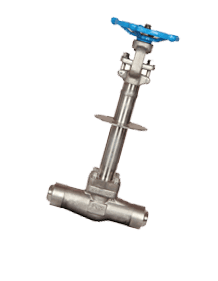

Stainless Steel 316L Forged Valves

SS 316L Forged Steel Valves, UNS S31603 Forged Steel Valves, SS 316L Forged Valves, 316L Forged Steel Valves, Stainless Steel 316L Forged Steel Valve Suppliers, DIN 1.4404 / 1.4435 Forged Steel Valves, Grade 316L Stainless Steel Forged Valves Manufacturers in Mumbai, India.

Virgin engineers are the professional manufacturer, stockiest and global exporter and supplier of the very good quality of Stainless steel 316L Forged Steel Valves. Very soon the industry is winged by the faster connection with global buyers and has got greater popularity dealing with a national and international clientele. This dealer is customer focused and in order to fulfill all the desires of buyers the steel valves are offered is varying in standards, pressure rating, sizes, temperature rating, working pressure, end connections, etc. To the global buyers, the product is supplied at custom made specifications and at market leading rates with sales after/before services.

Stainless Steel 316L Forged Globe Valves, Steel 316L Forged Check Valves, SUS 316L Forged Steel Valves, SS 316L Forged Integral Flanged End Valves Exporters, SS 316L Forged Steel Gate Valve, Gr. 316L Forged Steel Y-PATTERN Valves Supplier in Mumbai, India.

Stainless Steel 316L Welded Bonnet Forged Valves, SS 316L Bellow Sealed Valve, Stainless Steel 316L Flanged End Valve, SS 316L Cryogenic Valve, AISI 316L Forged Steel Valves, SS 316L Forged Steel Bolted Bonnet Valves.

Stainless steel 316L alloy information-

316L stainless steel is the second most austenitic stainless steel alloy. The main constituent of the alloy after iron is molybdenum, iron, and chromium. The addition of molybdenum alloying elements is providing very good corrosion resistance with respect to the localized attacks by the general corrosion and by chlorides by reducing acids like sulphuric acid. This grade alloy is a low carbon version of 316 SS. It is thus used in many industrial applications.

Properties of the product-

There are many excellent properties found in Stainless steel 316L Forged Steel valves due to which it has got greater popularity. The product is possessing high tensile strength, good dimensional accuracy, fine surface finishes, long-lastingness, anti-corrosive body, toughness, etc. Also, it is exhibiting very good stress corrosion cracking, crevice corrosion, pitting, oxidation, and carburization and withstands high temperature.

Manufacturing of the steel valves-

At the highly equipped industry, the production of Stainless steel 316L Forged Steel valves is done by using the very good quality of alloy. The designing of it is implemented by keeping in mind product quality standards and manufacturing process under the tight supervision of professional experts. Also to assure that manufactured product is offering 100% perfect dimensional accuracy and smooth surface finishes, the producers uses the latest technology and all modern tools for fabricating it.

Testing of the product-

There at the well-equipped industry, the testing of Stainless steel 316L Forged Steel valves are conducted by experts to check product quality. The tests done is like positive material identification test, pitting resistance test, hardness test, chemical test, intergranular corrosion test, and mechanical test.

Test certificates offered-

The test certificates offered to the buyers are including mill test certifications as per EN 10204/3.1B, third-party test report, 100% radiography test report, buyers test report, and raw material certificate.

Documents offered-

To the buyers the documents offered are like commercial invoice, fumigation certificate, heat treatment chart, quality assurance plan, packaging list, guarantee letter, raw material certificate, material traceability report, etc.

Delivering-

The delivering of the ordered consignment is guaranteed to be done well on time with no delays. The supplier takes the help of the fastest transportation means and reliable logistic partners. Also delivering is based upon availability of the product in stock but is shipped faster.

Packaging-

Stainless steel 316L Forged Steel valves are packed into the wooden cases, carton boxes and in environmental poly bags for safer, scratch free and damage free shipping.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel S31603 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 316L Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

ss 316l forged steel valves pressure sealed bonnet, stainless steel 316l socket welded forged steel valves, ss 316l pressure seal bonnet forged valves india, ss 316l forged steel valves welded bonnet design, ss 316l welded bonnet globe valves stockholder, stainless steel 316l flanged end check valves manufacturer in mumbai, parker stainless steel forged valves grade 316l, stainless steel 316l forged steel valves standards, stainless steel 316l forged steel globe valves, ss 316l bolted bonnet forged steel valves size, ss 316l forged seal welded valves , stainless steel 316l flanged end gate valves dealers, ss 316l bolted bonnet forged gate valves, stainless steel 316l forged steel pressure seal bonnet valves distributors, ss 316l flanged end globe valves stockists, ss 316l swagelok forged steel valves, buy high quality stainless steel 316l forged steel valves, ss 316l parker forged steel valves, stainless steel 316l forged steel valves types, ss 316l forged gate valves, ss 316l screwed forged steel valves traders, stainless steel 316l forged valves, ss 316l forged steel valves price.

© Copyright | Virgin Engineers 2021. All Right Reserved.