- Home

- Products

- Forged Steel Valves

- Stainless Steel 904L Forged Steel Valves

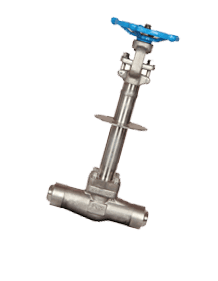

Stainless Steel 904L Forged Valves

Grade 904L Stainless Steel Forged Valves Suppliers, DIN 1.4539 Forged Steel Valves, SS 904L Forged Valves, 904L Forged Steel Valves, UNS N08904 Forged Steel Valves, Stainless Steel 904L Forged Steel Valve Manufacturers in Mumbai, India.

Virgin Engineers have profitably achieved the acknowledgment in the global market as a leading manufacturer, supplier, distributor and trader of Stainless Steel 904L Forged Steel Valves. We also deal with different types of ferrous and non-ferrous alloys. We are working with the vision to implement upgraded machinery in order to strengthen the productivity of the company. We are not working with any intermediate dealers we supply products directly to the customers. So, we are able to provide products at most reasonable rates. We set-up our company with an aim to retrieves some aspects that makes us an utmost choice for doing business with both small and large scale industries. These valves are made by us in the standard designations, custom dimensions, specifications, shapes, and sizes. We produce these valves under the national and international standard and per the design codes given by customers. We also accept non-standard dimensions as per their particular demands.

It is distinguished as a non- stabilized austenitic stainless steel grade with low carbon content. Additionally, it has copper content that improves resistance ability to high reducing acids. These valves are resistive against the stress corrosion cracking and crevice corrosion. This grade has non-magnetic properties even in the most severe environments. It has many features such as weldability, wettability, machinability, formability, and fabricability. It has some resisting elements such as molybdenum and nickel content. In most industrial applications, it can be induced in the heavy gauge applications. Stainless Steel 904L Forged Steel Valves have brilliant resistivity to warm sea water and chloride containing environments. Alloy 904L has higher resistance to stress corrosion cracking, due to the sufficient amount of nickel content. Additionally, these valves have resistance ability in mild and aggressive environments.

Steel 904L Forged Check Valves, SS 904L Forged Steel Gate Valve, Stainless Steel 904L Forged Globe Valves Exporters, SS 904L Forged Integral Flanged End Valves, SUS 904L Forged Steel Valves, Gr. 904L Forged Steel Y-PATTERN Valves Supplier in Mumbai, India.

SS 904L Bellow Sealed Valve, SS 904L Cryogenic Valve, Stainless Steel 904L Welded Bonnet Forged Valves, Stainless Steel 904L Flanged End Valve, SS 904L Forged Steel Bolted Bonnet Valves, AISI 904L Forged Steel Valves

Manufacturing details:

Generally, Stainless Steel 904L Forged Steel Valves are manufactured from hot and cold forging process. The temperature range is between 850 deg C to 1150 deg C, the same temperature is recommended for the hot working operations. The hot working operations are performed by a solution annealing process. In the case when the temperature is above 1100 deg C these valves are not preferred. After these operations, these valves are quenched directly with water or air.It is necessary to perform a cooling operation to achieve desired properties. Alloy 904L is weldable with all standard welding process and also fabricable with machines associated with this grade. SS 904L Forged Steel Valves have a homogeneous austenitic structure with an even portion of alloying elements. The separation of many elements like chromium, molybdenum, and nickel caused by solidification after welding

Knows about the tests each manufactured valves have to quality:

those tests are pitting corrosion test, valve seat leakage test, backseat test, closure test, shell leakage test, pneumatic test, hydrostatic test, Cryogenic testing, mechanical test, and low temperature testing. Other tests are burst tests, PMI test, fire safety tests, ultrasonic test, functional tests, drill stem test, IGC test, traveling valve test, radiographic test, and more.

If you are seeking best place to get Stainless Steel 904L Forged Steel Valves, then virgin engineers are best for you.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel N08904 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 904L Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 904l flanged end gate valves dealers, stainless steel 904l forged steel valves types, ss 904l welded bonnet globe valves stockholder, stainless steel 904l socket welded forged steel valves, stainless steel 904l flanged end valve, ss 904l bolted bonnet forged steel valves size, ss 904l forged steel valves pressure sealed bonnet, aisi 904l forged steel valves, ss 904l pressure seal bonnet forged valves india, ss 904l flanged end globe valves stockists, stainless steel 904l forged valves, ss 904l forged steel valves welded bonnet design, ss 904l forged seal welded valves, ss 904l forged gate valves, ss 904l parker forged steel valves, stainless steel 904l forged steel valves standards, parker stainless steel forged valves grade 904l, stainless steel 904l flanged end check valves manufacturer in mumbai, stainless steel 904l forged steel pressure seal bonnet valves distributors, stainless steel 904l welded bonnet forged valves stainless steel 904l forged steel globe valves, ss 904l cryogenic valve, ss 904l swagelok forged steel valves, ss 904l forged steel bolted bonnet valves, ss 904l bellow sealed valve, ss 904l forged steel valves price, ss 904l screwed forged steel valves traders, ss 904l bolted bonnet forged gate valves, buy high quality stainless steel 904l forged steel valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.