- Home

- Products

- Forged Steel Valves

- Stainless Steel 316Ti Forged Steel Valves

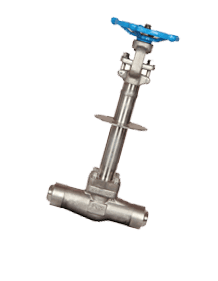

Stainless Steel 316Ti Forged Valves

SS 316Ti Forged Valves, Grade 316Ti Stainless Steel Forged Valves Suppliers, SS 316Ti Forged Steel Valves, DIN 1.4571 Forged Steel Valves, Stainless Steel 316Ti Forged Steel Valve, UNS S31635 Forged Steel Valves, 316Ti Forged Steel Valves Manufacturers in Mumbai, India.

Virgin engineers are a leading manufacturer and exporter of Stainless Steel 316Ti Forged Steel Valves that are being designed as per the international standard of quality. With advance machines and tested raw materials, we are able to draw production as per the set industrial norms. We are creating these forged steel valves in various standards, designations, custom dimensions, and altered shapes too. Our processing unit is very large and facilitated with advance machines makes us able to produce forged steel valves in large quantity. Meanwhile, we offer an inclusive range of all ferrous and non-ferrous grade products. Further, we can customize the production in terms of customer requirements and sizes that are hard to find.

Stainless Steel 316Ti Forged Steel Valves are titanium stabilized version of 316 grade molybdenum bearing austenitic stainless steel. Its designation number is 1.4571. This grade offers excellent resistance to general corrosion, crevice and pitting corrosion which is better than conventional nickel and chromium austenitic stainless steel. This version of 316 grades offers excellent stress to rupture, creep and tensile strength at higher temperatures. One exception, this grade is susceptible to sensitization. The formation of grain boundary precipitation starts in the temperature between 900-1500 deg F, results in the rapid corrosion.

In order to remove this issue lower amount of carbon is added on the alloy. Moreover, resistance to sensitization is achieved by the addition of titanium alloy that stabilizes the structure against chromium carbide precipitation. However, this stabilization is achieved by performing the heat treatment process in fluctuating temperatures. Significantly, the reduction of sensitization in service is decreasing the formation of chromium carbides. Due to its service against higher temperature, it can be used for extended periods at elevated temperatures without compromising the desired properties.

SS 316Ti Forged Steel Gate Valve, SS 316Ti Forged Integral Flanged End Valves, Gr. 316Ti Forged Steel Y-PATTERN Valves, SUS 316Ti Forged Steel Valves, Stainless Steel 316Ti Forged Globe Valves Exporters, Steel 316Ti Forged Check Valves Supplier in Mumbai, India.

AISI 316Ti Forged Steel Valves, SS 316Ti Cryogenic Valve, Stainless Steel 316Ti Flanged End Valve, SS 316Ti Bellow Sealed Valve, SS 316Ti Forged Steel Bolted Bonnet Valves, Stainless Steel 316Ti Welded Bonnet Forged Valves.

Quality standards:

Quality assurance here starts with understanding the requirements of the customers. It is completed until the customer is satisfied with the quality of the offered product and service. Our quality control procedures are well defined and thoroughly implemented in each section of the industry. Our company is built for best result oriented work culture to fulfill customer requirements in terms of cost, delivery, and quality. By improving the effectiveness of production plant and workforce we are aiming towards zero losses.

The zero error quality is achieved by our testing procedure performed in each level of production. Those tests are valve seat leakage test, backseat test, intergranular corrosion test, closure test, shell leakage test, pneumatic test, hydrostatic test, pitting corrosion test, and cryogenic testing. Other tests are low/ high temperature testing, burst tests, fire safe tests, functional tests, drill stem test, traveling valve test, ultrasonic test, etc.

Packaging and delivery criteria:

The manufactured range of forged steel valves is processed from the third party inspection before processing to dispatching unit. We pack these in the standard casing of plywood, wooden cartons, and pallets. Additionally, it is covered by a thin film of plastic in order to prevent contamination.

Get Stainless Steel 316Ti Forged Steel Valves from us and avail huge discounts as well high quality steel plates.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316Ti | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.395 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel S31635 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 316Ti Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 316ti forged steel globe valves, stainless steel 316ti socket welded forged steel valves, ss 316ti parker forged steel valves, ss 316ti pressure seal bonnet forged valves india, ss 316ti forged seal welded valves, ss 316ti bolted bonnet forged steel valves size, stainless steel 316ti flanged end gate valves dealers, buy high quality stainless steel 316ti forged steel valves, ss 316ti bolted bonnet forged gate valves, stainless steel 316ti forged valves, ss 316ti forged steel valves pressure sealed bonnet, stainless steel 316ti forged steel valves types, ss 316ti forged gate valves, ss 316ti forged steel valves price, ss 316ti screwed forged steel valves traders, ss 316ti forged steel valves welded bonnet design, stainless steel 316ti forged steel valves standards, ss 316ti flanged end globe valves stockists, stainless steel 316ti forged steel pressure seal bonnet valves distributors, stainless steel 316ti flanged end check valves manufacturer in mumbai, ss 316ti swagelok forged steel valves, parker stainless steel forged valves grade 316ti, ss 316ti welded bonnet globe valves stockholder.

© Copyright | Virgin Engineers 2021. All Right Reserved.