- Home

- Products

- Forged Steel Valves

- Stainless Steel 316H Forged Steel Valves

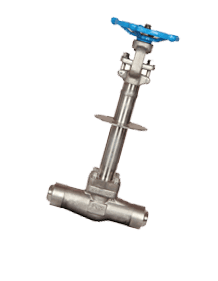

Stainless Steel 316H Forged Valves

SS 316H Forged Valves, Grade 316H Stainless Steel Forged Valves Suppliers, SS 316H Forged Steel Valves, DIN 1.4401 Forged Steel Valves, Stainless Steel 316H Forged Steel Valve, UNS S31609 Forged Steel Valves, 316H Forged Steel Valves Manufacturers in Mumbai, India.

As a highly acclaimed industry, Virgin enterprises are fully engaged in manufacturing and offering a high quality of Stainless steel 316H forged steel valves. We as a manufacturer, supplier, exporter and stockholder to the global and domestic buyers are offering the same at wider ranges so that all application desires are easily fulfilled. It is offered in standard specifications that vary in standards, sizes, working pressure, pressure rating, end connection, and temperature rating. We are having good years of knowledge and experience in the same sector so they are easily able to provide the product at custom made specifications.

Stainless steel 316H forged steel valves are having many good features to offer due to which it has got greater popularity and usability among the numbers of industrial applications. It is like reliability, durability, electro galvanized, cost effectiveness, high tensile strength, good dimensional accuracy, fine surface finishes, anti-corrosiveness, etc. it has resistance properties to pitting corrosion.

Gr. 316H Forged Steel Y-PATTERN Valves , Steel 316H Forged Check Valves, Stainless Steel 316H Forged Globe Valves Exporters, SUS 316H Forged Steel Valves, SS 316H Forged Integral Flanged End Valves, SS 316H Forged Steel Gate Valve Supplier in Mumbai, India.

SS 316H Forged Steel Bolted Bonnet Valves, SS 316H Bellow Sealed Valve, Stainless Steel 316H Flanged End Valve, SS 316H Cryogenic Valve, AISI 316H Forged Steel Valves, Stainless Steel 316H Welded Bonnet Forged Valves.

Production of the steel valves-

The production of the Stainless steel 316H forged steel valves; it begins up with the effective use of very good quality of raw materials. The alloy that they are using is collected from the reliable market mills and is tested and approved alloy. The production of the same is done under the strict guidance of professional experts that have a good understanding of how the product fabrication is done with the fullest perfection. They thus guide every worker in making the product that could 100% dimensional accuracy and smooth surface finishes of the product.

Also, we make use of available advanced technology and modern tools for fabricating the high quality of the same. Moreover, it is fabricated as per raw material quality standards and set manufacturing norms.

Alloy description-

316H is the high carbon modification of the alloy 316 and is developed for use at the elevated temperature services. The alloy is having very good strength at ranges of temperature and it is used for the structural as well as pressure vessel applications at the temperature ranging more than 932 Deg F. The high carbon content of this alloy is delivering the high tensile strength than the 316/316L. Their austenitic structures provide the alloy toughness down to the cryogenic temperature.

The alloy corrosion resistance is good and it is used at the process streams that are having halide and chloride. The alloy is resisting atmospheric corrosion and reducing and oxidizing atmosphere. It also resists corrosion at the polluted marine conditions. This alloy is non-magnetic at the annealed condition and can’t be welded through heat treatment. The material will be easily hardened because of the cold working process.

Testing-

The testing of the manufactured ranges of Stainless steel 316H forged steel valves is done for its quality assurance. The tests are done by the expert’s team and with the help of best tools. PMI test, IGC test, hardness test, mechanical test, chemical test, etc are performed. This assures that none of any poor quality product is delivered to the buyers.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS |

| SS 316H | 1.4401 | S31609 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel S31609 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 316H Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

ss 316h bolted bonnet forged gate valves, ss 316h flanged end globe valves stockists, stainless steel 316h forged steel valves standards, parker stainless steel forged valves grade 316h, stainless steel 316h flanged end check valves manufacturer in mumbai, ss 316h forged steel valves welded bonnet design, stainless steel 316h forged valves, buy high quality stainless steel 316h forged steel valves, ss 316h forged steel valves price, ss 316h screwed forged steel valves traders, ss 316h bolted bonnet forged steel valves size, ss 316h forged steel valves pressure sealed bonnet, ss 316h forged seal welded valves, stainless steel 316h forged steel globe valves, stainless steel 316h forged steel pressure seal bonnet valves distributors, ss 316h welded bonnet globe valves stockholder, ss 316h swagelok forged steel valves, stainless steel 316h forged steel valves types, stainless steel 316h socket welded forged steel valves, ss 316h parker forged steel valves, ss 316h pressure seal bonnet forged valves india, stainless steel 316h flanged end gate valves dealers, ss 316h forged gate valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.