- Home

- Products

- Forged Steel Valves

- Stainless Steel 317 / 317L Forged Steel Valves

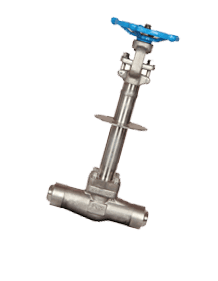

Stainless Steel 317 / 317L Forged Valves

DIN 1.4449 Forged Steel Valve, UNS S31703 Forged Steel Valves, UNS S31700 Forged Steel Valves, 317 Forged Steel Valves, DIN 1.4438 Forged Steel Valves, 317L Forged Steel Valves , SS 317L Forged Valves, Stainless Steel 317 Forged Valves, Stainless Steel 317L Forged Valves Suppliers, SS 317 Forged Valves Manufacturers in Mumbai, India.

Virgin engineers are the reputed and leading manufacturers of Stainless Steel 317 / 317L Forged Steel Valves that are used in various industrial applications and instrumentation applications. The valves are considered best for regulating and controlling the flow of fluids. However, being an ISO certified company we are always engaged in maintaining the high quality of our products. We are making use of high-tech machinery and technology so that we can manufacture the best quality product and reduce labor work. Along with providing a high-quality product, they provide other services like accurate dimension, surface finishing and 24 hours customer support service. You can also buy these stainless steel forged steel valves in different forms, shapes, and sizes. Our aim is to offer our customer the best quality valves hence we make sure that all our products are well tested and certified by the testing professionals.

Gr. 317L Forged Steel Y-PATTERN Valves, SS 317 Forged Integral Flanged End Valves Exporters, SS 317 Forged Steel Gate Valve, Steel 317L Forged Check Valves, Grade 317 / 317L Stainless Steel Forged Valves, SUS 317 / 317L Forged Steel Valves, Stainless Steel 317 Forged Globe Valves Supplier in Mumbai, India.

Stainless Steel 317 Flanged End Valve, SS 317L Cryogenic Valve, AISI 317 / 317L Forged Steel Valves, Stainless Steel 317 Welded Bonnet Forged Valves, SS 317L Bellow Sealed Valve, SS 317 Forged Steel Bolted Bonnet Valves.

About the product and its manufacturing details

Forged steel valves are compact and rugged in design that is made available for industries in different types. These valves help in controlling the pressure of fluids. These valves are made as per the national and international specifications and standards. For manufacturing these stainless steel forged steel valves premium quality of the material is used that is properly tested and inspected before it is transferred for the manufacturing process. When the material is properly tested and inspected it is sent for the manufacturing process where our qualified professionals make sure that every material is used in the best way for making a high-quality product. The experience of professionals and the use of latest machinery and technology help in manufacturing valves of different forms as required by the clients and customers.However, if we talk about the features of these forged steel valves there are several features offered like longer life, positive shut-off, no lubrication, low-pressure drop, compact design, simplicity and quick in action. All these features allow valves to easily perform its best under different climatic conditions and pressure.

About stainless steel 317/317L

Stainless steel 317/317L is also known with the standard designation as UNS S31703. It is a molybdenum bearing, carbon content austenitic stainless steel grade that offers excellent resistance to corrosion. On another hand, 317L has a lower amount of carbon that provides resistance to sensitization at the time of the thermal and welding process. It is non-magnetic in the annealed condition but often becomes magnetic at the time of welding. Its excellent features make it suitable for manufacturing products like forged steel valves.

Testing and packaging

Talking about the testing process manufacturers in order to, check the quality of these forged steel valves conducts various tests. There are several tests done like flaring test, flattening test, hardness test, third-party inspection, ultrasonic test, radiography test and more. All the tests are done as per the industrial rules and regulations. Once all the tests are done, these Stainless Steel 317 / 317L Forged Steel Valves are approved and transferred for the packaging process.

These valves are then packed in wooden cartons or boxes that help avoid damages and rust.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel S31700, S31703 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 317 / 317L Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

ss 317 parker forged steel valves, ss 317 screwed forged steel valves traders, stainless steel 317l socket welded forged steel valves, stainless steel 317 forged valves, ss 317 swagelok forged steel valves, stainless steel 317 forged steel pressure seal bonnet valves distributors, ss 317 flanged end globe valves stockists, ss 317 forged steel valves price, stainless steel 317l forged steel globe valves, stainless steel 317 flanged end check valves manufacturer in mumbai, ss 317l bolted bonnet forged steel valves size, ss 317l forged gate valves, ss 317l forged steel valves welded bonnet design, buy high quality stainless steel 317 forged steel valves, parker stainless steel forged valves grade 317/317l, stainless steel 317l forged steel valves, ss 317l welded bonnet globe valves stockholder, ss 317 pressure seal bonnet forged valves india, stainless steel 317l flanged end gate valves dealers, ss 317 bolted bonnet forged gate valves, stainless steel 317 forged steel valves standards, ss 317l forged seal welded valves, ss 317 forged steel valves pressure sealed bonnet, stainless steel 317l forged steel valves types.

© Copyright | Virgin Engineers 2021. All Right Reserved.