- Home

- Products

- Forged Steel Valves

- Stainless Steel 347 / 347H Forged Steel Valves

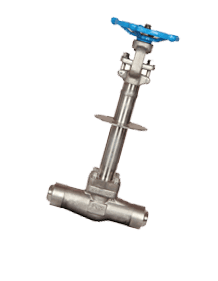

Stainless Steel 347 / 347H Forged Valves

SS 347H Forged Valves, SS 347 Forged Valves, DIN 1.4961 Forged Steel Valves, Stainless Steel 347H Forged Valves Suppliers, UNS S34700 Forged Steel Valves, DIN 1.4550 Forged Steel Valve, Stainless Steel 347 Forged Valves, UNS S34709 Forged Steel Valves, 347 Forged Steel Valves, 347H Forged Steel Valves Manufacturers in Mumbai, India.

Virgin Engineers is the best industry that is fully involved in manufacturing and providing the comprehensive ranges of Stainless steel 347 / 347H Forged Steel Valves. We are globally dealing as a reliable manufacturer, supplier, stockiest and exporter of the superior quality of forged steel valves. A buyer seeking for buying this can get it at different dimensions, standards, sizes, working pressure, pressure rating, end connections, temperature rating, etc. It is supplied to the buyers within the set time framed of delivering without delays. With regards to raw material quality standards, the same is provided at custom made specifications same as per the demands made by the buyers.

Columbium stabilized austenitic stainless steel 347 alloy is with very good general corrosion resistance and somewhat a better resistance at the strong oxidization conditions. It is having very good resistance to intergranular corrosion when get exposed to the temperature ranging 800-1500 Deg F. This alloy is having very good resistance and creep resistance to 816 Deg C. This alloy is possessing very good low-temperature toughness. Alloy 347H is the high carbon content version 347 alloys. This alloy is developed for the purpose of enhancing the creep resistance and for the high strength at the temperature ranging from 1000 Deg F. In many cases the carbon content is enabling the dual certifications.

SS 347 Forged Steel Gate Valve, Stainless Steel 347 Forged Globe Valves, Steel 347H Forged Check Valves, SUS 347 / 347H Forged Steel Valves, Gr. 347H Forged Steel Y-PATTERN Valves, Grade 347 / 347H Stainless Steel Forged Valves Exporters, SS 347 Forged Integral Flanged End Valve Supplier in Mumbai, India.

SS 347H Bellow Sealed Valve, Stainless Steel 347 Welded Bonnet Forged Valves, SS 347 Forged Steel Bolted Bonnet Valves, SS 347H Cryogenic Valve, Stainless Steel 347 Flanged End Valve, AISI 347 / 347H Forged Steel Valves.

Manufacturing of the product-

The manufacturing of Stainless steel 347 / 347H Forged Steel Valves begins with the effective utilization of high quality of raw materials that are well tested. The manufacturing of the product is conducted under the tight supervision of professional expert that are having very good skills and knowledge on how the product is developed with fullest perfections that assure. We are making the stunning quality of forged steel valves that is by keeping in mind several raw material quality standards and production guidelines that are set up by the manufacturing industry. The production of the same is done the same per the well-defined manufacturing norms and raw material quality standards. This helps the producers to deliver the excellent quality of product guaranteeing 100% dimensional accuracy, fine surface finishes, etc.

Testing of the product-

The testing of Forged Steel Valves is done by the expert’s team so that the quality of the product can be well checked. All the manufactured ranges of Stainless steel 347 / 347H Forged Steel Valves are sent for the testing so that error-free quality of the product is supplied to the buyers. The tests done are like positive material identification test, chemical test, micro test, macro test, ultrasonic test, flattening test, flaring test, mechanical test, intergranular corrosion test, visual inspection, etc.

Documenting of the product-

By the industry, to all esteem patrons, all important documents are provided. Some of them are like heat treatment chart, quality assurance plan, raw material test report, material traceability report, packaging list, NABL approved lab test report, and guarantee letter is offered. The test certifications like MTC as per EN 10204/3.1b, radiography test report, third-party test report is offered.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | - | X6CrNiNb18-12 |

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 20.00 | 10xC – 1.10 | 9.00 - 13.00 | 62.74 min |

| SS 347H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Stainless Steel S34700, S34709 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 347 / 347H Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

ss 347h forged gate valves, ss 347 parker forged steel valves, stainless steel 347h forged steel valves types, ss 347 forged steel valves price, ss 347 swagelok forged steel valves, stainless steel 347 forged steel pressure seal bonnet valves distributors, ss 347 pressure seal bonnet forged valves india, ss 347h forged seal welded valves, stainless steel 347h forged steel globe valves, stainless steel 347 forged steel valves standards, ss 347 bolted bonnet forged gate valves, parker stainless steel forged valves grade 347/347h, stainless steel 347h forged steel valves, ss 347h welded bonnet globe valves stockholder, buy high quality stainless steel 347 forged steel valves, stainless steel 347 forged valves, stainless steel 347h socket welded forged steel valves, ss 347 flanged end globe valves stockists, stainless steel 347 flanged end check valves manufacturer in mumbai, ss 347 screwed forged steel valves traders, ss 347h forged steel valves welded bonnet design, stainless steel 347h flanged end gate valves dealers, ss 347 forged steel valves pressure sealed bonnet, ss 347h bolted bonnet forged steel valves size.

© Copyright | Virgin Engineers 2021. All Right Reserved.