- Home

- Products

- Forged Valves

- Manifold Valves

- Super Duplex Steel S32750 / S32760 Manifold Valves

Super Duplex Steel S32750 / S32760 Manifold Valves

S32750 Super Duplex Manifold Valves, Super Duplex S32760 2 Way Manifold Valve, Super Duplex Steel S32750 / S32760 Valve Manifold, SAF 2507 Instrument Manifold Valves Suppliers, DIN 1.4410 Manifold Valve, Super Duplex Steel S32750 3 Way Manifold Valves, Super Duplex Steel S32750 Manifold Valves, Super Duplex S32760 5 Way Manifold Valves Manufacturers in Mumbai, India.

Virgin engineers are supplying all types of manifold valves with numerous worldwide sources for limitless applications. We are supplying Super Duplex Steel S32750 / S32760 Manifold Valves in exotic standard, specifications, shapes, designations and altered dimensions. We have an extensive project experience makes us able to produce products compatible with international standards of quality. We are facilitated with fast and expert logistical management. This makes us do speedy deliveries. Working with highly trained personnel and management we have gained ISO accreditations.

Super Duplex Steel S32750 Direct-Mount Manifolds, SAF 2507 Manifold Valves, Super Duplex S32750 Remote-Mount Manifold Exporters, Super Duplex S32760 3 Valve Manifold, Super Duplex Steel S32750/S32760 Valves Manifolds, Super Duplex Stainless Steel S32760 2 Valve Manifold, Super Duplex Steel S32750 / S32760 5 Valve Manifold Supplier in Mumbai, India.

Super Duplex S32760 Hydraulic Manifold, Super Duplex Stainless Steel S32760 H Series Manifold Valves, Super Duplex Steel S32750 Bellows Sealed Manifolds, Super Duplex S32750 Remote-Mount, Super Duplex S32750 / S32760 Instrumentation Manifold Valves, Super Duplex S32750/S32760 Block and Bleed Valves, SAF 2507 R - Type Manifold Valve, Super Duplex Steel S32750 Double Block Bleed Valves, Super Duplex 2507 V/ VB and VL series Manifolds, Super Duplex S32760 Three Way T- Type Manifold Valves.

Super Duplex Steel S32750 / S32760 Manifold Valves have dual- phase microstructure that consists of austenitic and ferritic structures. The ferritic structure covers the austenitic structure. It is melted to achieve full ferritic structure. In the cooling process, its ferritic structure changes half into the austenitic structure. Therefore it gets a 50-50 ratio ferritic an austenitic structure. This dual phase structure and properties, it is recommended one of the best engineering materials that are used for the fabrication of manifold valves.

It has a duplex structure that offers this grade a great combination of attractive attributes. These grades have double strength compare to standard ferritic and austenitic grade. It has great ductility and toughness. However, it is able to deliver properties same as austenitic grades.

The corrosion resistance ability depends on its composition. It is having a combination of chromium, nitrogen, and molybdenum that offer resistance to pitting and crevice corrosion.

We are committed to provide competitive products and service to our focus industry working on the field of manifold valves. At every stage of our business operations, we seek to implement a process that leads to satisfying customer satisfaction. We are continually improving the effectiveness of our quality management system and set quality objectives and work plans. We are focused to upgrade the capabilities of our technical and administrative staff through formal training and regular technical quality awareness. Here we provide only premium quality products to the customers while assisting them to choose the right type of products as per their application requirements.

The manufactured manifold valves are processed under different types of tests that regulate quality in each section of our business. The tests are followed in sequence ranges from metallurgical tests such as pitting corrosion test, radiography, IGC test, positive material test, ultrasonic test, micro analysis, and macro analysis. Other tests include destructive test valve seat leakage test, shell leakage test, pneumatic test, hydrostatic test, cryogenic testing, low temperature testing, burst tests, fire safe tests, functional tests, drill stem test, etc.

Fumigation certificates, commercial invoice, national board approval lab (NBAL) test certificate, raw material test report, mill test report, quality assurance plan, specification guide, and heat treatment charts.

As for the safety of products at the time of delivery we use industrial prominent packaging materials. These manifolds are packed in the wooden cages, cartons, pallets and customized packing. Place an order for Super Duplex Steel S32750 / S32760 Manifold Valves and avail huge discounts.

Specification

ASTM

ASME / ASTM A995/A182/A351/A890

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| 7.8 | 0.281 | 1350 | 2460 |

Products

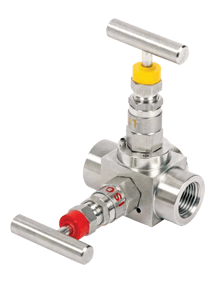

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

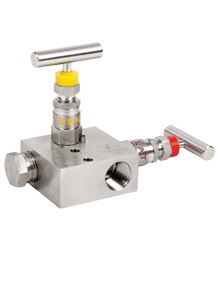

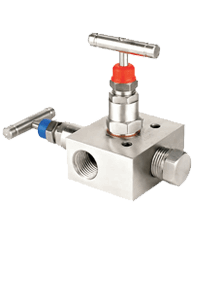

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

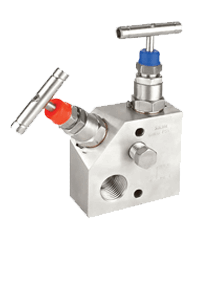

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Super Duplex Steel S32750 / S32760 manifold valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Super Duplex Stainless Steel S32750 / S32760 manifold valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

super duplex steel s32750 3 way manifold price list, super duplex s32750/s32760 manifold valve size, super duplex steel s32760 manifold 3 valves 2 ways, super duplex steel s32760 manifold hydraulic valves, super duplex s32760 manifold valves manufacturers in india, super duplex steel s32760 manifold valves manufacturer in mumbai, super duplex stainless s32750/s32760 manifold valves traders, saf 2507 manifold mounted ball valves, s32750/s32760 super duplex steel manifold valve application, s32750 super duplex steel types of manifold valves, super duplex s32750 manifold valves price, super duplex steel s32760 manifold valves types, super duplex steel s32750 5 valve remote mounted, super duplex s32760 manifold valves stockists, super duplex steel s32750 / s32760 manifold valve dealers, buy high quality super duplex steel s32760 manifold valves, super duplex stainless steel s32750 / s32760 manifold valves stockholder, super duplex steel s32750 manifold valves distributors, super duplex s32750 2 way manifold valve for pressure gauge, super duplex steel s32750 3 valve direct mounted, saf 2507 2 valve t type manifold valve.

© Copyright | Virgin Engineers 2025. All Right Reserved.