- Home

- Products

- Valves

- Manifold Valves

- Alloy 20 Manifold Valves

Alloy 20 Manifold Valves

Alloy 20 Valve Manifold, Alloy 20 3 Way Manifold Valves, UNS N08020 Manifold Valves, Carpenter 20 5 Way Manifold Valves Suppliers, Alloy 20 CB-3 2 Way Manifold Valve, DIN 2.4660 Manifold Valve, Alloy 20 Instrument Manifold Valves Manufacturers in Mumbai, India.

Virgin engineers are one of the prime manufacturer, suppliers, and exporters of a great variety of Alloy 20 Manifold Valves. We are a global distributor of manifold valves with speedy delivery options. We are stocking the manifold valves in different shapes, specifications, standards, designations, sizes and as per customer requirements. We have been manufacturing manifold valves by the use of the finest grade of raw materials. These are fabricated from trending machines and equipment. Therefore, these valves get desired dimensions as per the set industrial norms. Alloy 20 manifold valves are mostly preferred by the engineers due to its beneficial features some are resistant to corrosion and abrasion. Its dimension accuracy is enhanced by performing industrial finishing process, moreover, it is coated with industrial coats adds prevention from contamination.

Alloy 20 Hydraulic Manifold, Alloy 20 Three Way T- Type Manifold Valves, Alloy 20 Remote-Mount, Alloy 20 Bellows Sealed Manifolds, Carpenter 20 CB-3 H Series Manifold Valves, Alloy 20 Block and Bleed Valves, Alloy 20 R - Type Manifold Valve, Alloy 20 Double Block Bleed Valves, Alloy 20 Instrumentation Manifold Valves.

Alloy 20 Valves Manifolds, Alloy 20 2 Valve Manifold, Alloy 20 Remote-Mount Manifold Valve, Alloy 20 5 Valve Manifold, Alloy 20 Direct-Mount Manifolds Exporters, Alloy 20 3 Valve Manifold Supplier in Mumbai, India.

Alloy 20 is made up the composition of nickel, chromium, and iron content. This is austenitic grade with elevated corrosion resistance ability even in the chemical reducing zones such as sulfuric acids environments. This grade is stable with niobium element that resists intergranular corrosion attacks. These manifold valves are a potential cost saving option when compared to other standard grades. Moreover, alloy 20 is ideal for processing for severe chemical compound processing such as nitric acid, phosphoric acid, and salt solutions. Alloy 20 made manifold valves are a solid solution for chloride corrosion cracking environments. This manifold can also be exposed in the pitting and crevice corrosive environments. Special consideration should be taken in chloride containing environment because of corrosion rate increases.

Manufacturing of Alloy 20 Manifold Valves: - The manifold valves can be formed either by cold and hot working operation using standard methods. the hot working operation is performed under the controlled temperatures in temperature between 2100- 2250 deg F. this temperature should be maintained up to 1800 deg F. moreover, to attain higher mechanical properties annealing process is performed in temperature up to 1850 deg F. it is quenched with water. If required stress relieving process is performed, it is heated in down temperature below 1000 deg F for a limited time and controlled the temperature. The down temperature properties are attained by addition of heating in at temperature 2100 deg F, maybe this put a negative effect on the stabilization.

Those are Valve seat leakage test, pitting corrosion test, backseat test, closure test, shell leakage test, pneumatic test, intergranular corrosion test, hydrostatic test, and cryogenic testing. Other tests are temperature testing, radiographic test, relief test, transfer valve test, drill stem test, traveling valve test, ultrasonic test, etc.

Essential documentations-

Commercial invoice, QAP, heat treatment charts, specification guide, fumigation certificates, stamping details, national board approval lab (NBAL) test report, MTC report, attested certificate by suppliers, mill test report, etc.

Alloy 20 Manifold Valves are delivered in the standard packing of wooden cases, pallets, plywood boxes with additional support. Customized packing is provided with a thin film of plastic to add protection from contamination.

Alloy 20 Manifold Valves for long lasting applications are now available in different forms and dimensions.

Specification

ASTM

ASTM A494 / ASME SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | EN |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo |

| Grade | Ni | C | Mn | P | S | Si | Cr | Nb | Mo | Cu |

| Alloy 20 | 32 - 38 | 0.02 max | 1 - 2 | 0.02 max | 0.005 max | 0.7 max | 19 - 21 | 0.1 - 0.3 | 2 - 3 | 3 - 4 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi - 35,000, MPa - 241 | 30 % |

Products

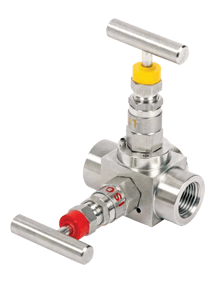

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

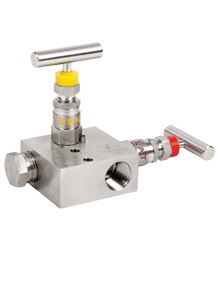

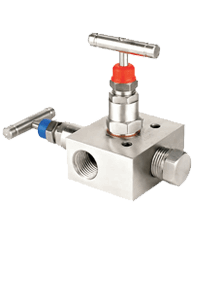

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

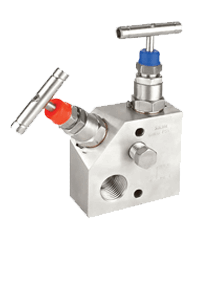

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Alloy UNS N08020 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Alloy 20 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

alloy 20 manifold valves manufacturer in mumbai, alloy 20 manifold valves stockholder, alloy 20 manifold valves price, alloy 20 3 valve direct mounted, alloy 20 manifold valve application, buy high quality alloy 20 manifold valves, alloy 20 manifold valve dealers, alloy 20 manifold mounted ball valves, alloy 20 manifold valves traders, alloy 20 3 way manifold price list, alloy 20 manifold valve size, alloy 20 manifold valves types, alloy 20 2 valve t type manifold valve, alloy 20 5 valve remote mounted, alloy 20 manifold 3 valves 2 ways, alloy 20 manifold valves distributors, alloy 20 manifold valves manufacturers in india, alloy 20 manifold valves stockists, alloy 20 2 way manifold valve for pressure gauge, alloy 20 types of manifold valves, alloy 20 manifold hydraulic valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.