- Home

- Products

- Forged Valves

- Titanium Gr 5 Forged Valves

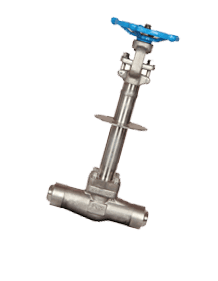

Titanium Gr 5 Forged Valves

Virgin engineers are leading the way as high-quality manufacturers for satisfying different application needs. Whenever a buyer needs titanium valves for any purpose, they are welcomed to this company site, where they can choose the product and place an order to satisfy all their desires.

We are providing superior quality Titanium Gr 5 forged steel valves with greater performance. The alloy valves are high-pressure valves suitable for all desired applications. As per the latest customer requirements and market trends, we provide the same specifications.

As a top-ranking industry with a wider range of forged steel valves, we offer them in different dimensions, standards, pressure ratings, end connections, types, and sizes. We also provide them to buyers at customized specifications to satisfy application needs. We supply these valves to domestic and international customers.

Grade 5 Ti description-

Titanium Gr 5 is a two-phase alpha and beta grade widely used in all grades of titanium alloy. It is supplied in the annealed condition according to AMS 4928R for machinability ease, and it can easily be strengthened with simple heat treatment that offers very good mechanical properties. The combination of good mechanical properties and excellent corrosion resistance ability makes Ti Gr 5 right for various applications.

Manufacturing of forged steel valves-

At our forged steel valve manufacturing unit, our professional expert stringently tests and inspects the whole products on various levels of production in order to ensure a quality range and defect-free product. These tests include macro and micro tests, cryogenic testing, pneumatic testing, hydrostatic testing, chemical analysis, pitting resistance tests, and leakage tests.

Titanium Gr 5 forged steel valve manufacturing is conducted with the fullest care and perfection to bring out the stunning quality of the product. The same is manufactured by effectively using the purest quality of raw materials. Also, producers effectively use refined technology and modern tools during product development. The development of TI Gr5 steel valves is done as per national and international product quality standards. Also, the producers are developing the steel valves per set manufacturing norms.

Testing of the steel valves-

The testing is mandatory to ensure the error-free quality of the product to the buyers. The tests done are intergranular corrosion test, pitting resistance test, mechanical test, chemical test, hardness test, positive material identification test, etc. Other material tests are performed for end application requirements.

Test certification-

The test certifications provided to the global buyers are like mill test certificates as per EN 10204/3.1B, third-party test reports, buyers reports, radiography test reports, etc

Documenting-

Important documents, such as commercial invoices, packaging lists, NABL-approved test reports, guarantee letters, raw material test reports, etc., are provided to the buyers. This creates buyer confidence in the dealer and leads to more deals.

Packaging-

To ensure rust-free, damage-free, and scratch-free shipping, the steel valves' packaging is done with full care using environmental poly bags and wooden/carton boxes. Thus, the product reaches the buyers in good condition.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | UNS | WNR. |

| Titanium Gr 5 | N56400 | 3.7165 |

| Grade | Ti | C | Fe | H | N | O | Ai | V |

| Titanium Gr 5 | 90 min | - | 0.25 max | - | - | 0.2 max | 6 min | 4 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000, MPa – 950 | Psi – 128000, MPa – 880 | 14 % |

Products

Forged Globe Valve

Forged Gate Valve

Forged Flanged End Valves

Forged Check Valves

Forged Extended Body Valves

Forged Y-PATTERN Valves

Forged Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Titanium N56400 Forged Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Titanium Gr 5 Forged Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

alloy Gr 5 forged valves price, Titanium Gr 5 socket welded forged valves, Titanium Gr 5 forged pressure seal bonnet valves distributors, Titanium® alloy Gr 5 screwed forged valves traders, parker Titanium forged valves grade Gr 5, alloy Gr 5 forged valves welded bonnet design, Titanium Gr 5 forged valves, Titanium Gr 5 forged valves standards, alloy Gr 5 flanged end globe valves stockists, Titanium alloy Gr 5 bolted bonnet forged gate valves, alloy Gr 5 pressure seal bonnet forged valves india, buy high quality Titanium® Gr 5 forged valves, alloy Gr 5 bolted bonnet forged valves size, Titanium Gr 5 forged globe valves, Titanium alloy Gr 5 welded bonnet globe valves stockholder, Titanium® Gr 5 forged valves types, alloy Gr 5 forged valves pressure sealed bonnet, Titanium® Gr 5 flanged end check valves manufacturer in mumbai, Titanium alloy Gr 5 swagelok forged valves, Titanium Gr 5 flanged end gate valves dealers, Titanium alloy Gr 5 parker forged valves, alloy Gr 5 forged gate valves, alloy Gr 5 forged seal welded valves.

© Copyright | Virgin Engineers 2025. All Right Reserved.