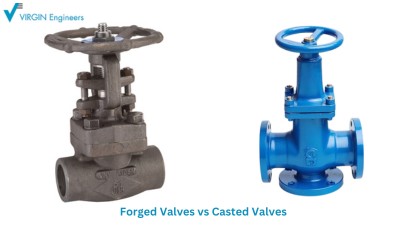

Valves play a crucial role in controlling the flow of liquids, gases, and slurries across industries like oil & gas, petrochemicals, water treatment, power generation, and manufacturing. When selecting the right valve, one of the biggest decisions is choosing between forged valves and casted valves. Both types are strong, reliable, and widely used — but…

A Complete Guide to Bleed Valve Function

Bleed valves are small but essential components used across oil & gas, chemical, refinery, power generation, and instrumentation systems. Their primary function is to safely release trapped air, gas, or liquid from pipelines and equipment, ensuring minimal pressure fluctuations and maximum safety. At Virgin Engineers, we manufacture high-performance bleed valves designed to deliver reliable venting…

Ball Valve Uses

Ball valves are among the most widely used valve types in industrial and commercial systems due to their durability, quick shut-off capabilities, and ease of operation. With a simple quarter-turn mechanism and a tight seal, ball valves are designed to control the flow of liquids or gases efficiently, even under high pressure and temperature. At…

10 Reasons to Choose Stainless Steel High Pressure Pipe Fittings for Industrial Use

In today’s fast-paced industrial world, selecting the right materials for your piping systems is critical. High pressure pipe fittings are essential components in systems that carry gases, liquids, or chemicals under significant force. These systems are found in oil refineries, chemical plants, food processing units, and many more. Among the many materials available, stainless steel…

Gauge Valve Function – Purpose, Working & Industrial Use

In industrial systems, precise pressure measurement is critical for ensuring operational safety and efficiency. That’s where gauge valves come into play. At Virgin Engineers, we manufacture and supply high-performance gauge valves that are designed to regulate, isolate, and protect pressure gauges in a variety of process systems. Let’s explore the function, working, and applications of…

What is Quick Coupling?

In modern industrial applications, efficiency and safety are non-negotiable — especially when dealing with fluid and gas transfer systems. One component that plays a vital role in streamlining these operations is the quick coupling. Also known as a quick connect or quick disconnect fitting, this device allows for fast and easy connection and disconnection of…

Ball Valve vs Gate Valve: Key Differences Explained

In industrial piping systems, valves are critical for controlling flow, pressure, and safety. Two of the most commonly used types are ball valves and gate valves. While both are designed to start or stop fluid flow, their internal mechanics, applications, and efficiency differ significantly. As a leading manufacturer and supplier of industrial valves, Virgin Engineers…

Needle Valve Uses: Precision Control with Virgin Engineers

In the world of fluid control, where precision and accuracy are critical, needle valves play a vital role. Known for their fine threading and slender, tapered point, needle valves allow for precise regulation of flow—making them essential in industries that demand exact fluid or gas control. At Virgin Engineers, we manufacture and supply high-performance needle…

What is a Manifold Valve?

A manifold valve is a precision-engineered device used to regulate, isolate, vent, or equalize pressure in fluid and gas systems—particularly in instrumentation and process control applications. It combines multiple valve functions into a single compact body, streamlining the piping setup and improving efficiency. At VIRGN ENGINEERS, we specialize in high-performance 2-valve, 3-valve, and 5-valve manifolds,…

Titanium Valves vs. Stainless Steel Valves: Which One to Choose?

Valves play a crucial role in industries such as oil & gas, marine, chemical processing, power generation, and aerospace, controlling the flow of fluids and gases. The choice of valve material significantly impacts performance, durability, and cost-effectiveness. Among the most commonly used options are titanium valves and stainless steel valves, each offering distinct advantages. While…