In the world of industrial applications, selecting the right valve is essential for ensuring smooth operations and precise control of fluid flow. Among the most commonly used valves are ball valves and needle valves, each designed for specific purposes. Understanding their differences is crucial to optimizing system performance. Let’s explore the key distinctions between these two valve types to help you make an informed decision.

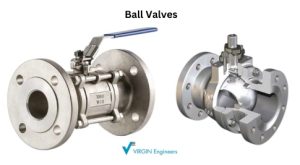

What is a Ball Valve?

A ball valve is a type of shut-off valve that controls fluid flow using a rotary ball with a central bore. Known for its efficiency, a ball valve operates with a quick 90-degree turn, making it extremely user-friendly. These valves are highly durable and can withstand high-pressure and high-temperature systems, making them a versatile choice for industrial use.

Ball valves are widely used in applications such as oil and gas pipelines, water and wastewater systems, and HVAC systems, where rapid flow control and long-term reliability are essential. Their robust design and minimal maintenance requirements make them a preferred choice for various industries.

What is a Needle Valve?

A needle valve is designed for precise control of flow, particularly in low-flow applications. Unlike ball valves, which provide quick on/off control, needle valves offer incremental adjustments, allowing operators to fine-tune flow rates. The valve features a tapered needle-like plunger that fits into a small orifice, providing a high level of precision.

Needle valves are commonly used in instrumentation systems, gas metering in laboratories, and hydraulic systems where accuracy is critical. These valves are ideal for applications requiring controlled flow, but they are not suited for high-flow operations. Their gradual control mechanism makes them indispensable in settings demanding meticulous adjustments.

Ball Valve vs Needle Valve

| Feature | Ball Valve | Needle Valve |

|---|---|---|

| Function | Designed for on/off control in high-flow systems. | Provides precise flow regulation in low-flow systems. |

| Design | Features a rotary ball with a bore that opens or blocks flow. | Includes a tapered needle-like plunger for gradual adjustments. |

| Flow Rate Handling | Suitable for high-flow systems, allowing quick operation. | Ideal for low-flow systems where accuracy is critical. |

| Operation | Operates with a simple 90-degree turn for quick opening/closing. | Requires careful incremental adjustments for flow control. |

| Applications | Used in industrial pipelines, water systems, HVAC, and oil and gas industries. | Commonly used in instrumentation systems, gas metering, and laboratory setups. |

| Durability | Highly durable, capable of withstanding high pressure and temperature. | Moderately durable, optimized for precision and accuracy. |

| Ease of Use | User-friendly and simple to operate with minimal maintenance. | Requires careful handling and more maintenance due to its design. |

| Material Options | Typically made from stainless steel, brass, or PVC for high strength. | Made from stainless steel or brass for corrosion resistance. |

| Cost | Generally cost-effective for high-demand systems. | Higher cost due to precision engineering and limited applications. |

At Virgin Engineers, we take pride in offering premium-quality ball valves and needle valves designed to meet diverse industrial requirements. Whether you need a durable solution for high-pressure pipelines or a precision valve for instrumentation systems, we have the expertise and product range to deliver. Our valves are crafted from high-grade materials, ensuring longevity and optimal performance.

For expert guidance or to explore our wide range of industrial valves, contact us at +91 22 23699202 today. Let us help you find the perfect solution for your applications.