Needle valves are an essential component in many fluid and gas control systems, providing precise flow regulation in various industries. Whether used in high-pressure systems or delicate fluid flow control, the needle valve offers versatility and precision that other valve types might not provide. This blog explores the functionality, design, and applications of needle valves, helping you understand why they are a preferred choice for controlling flow in industrial systems.

What Is a Needle Valve?

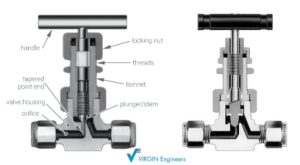

A needle valve is a type of valve used to control the flow of liquids or gases through a system. It gets its name from the long, tapered needle-like plunger that fits inside the valve body. This needle design allows for very fine and precise adjustments of the flow, making needle valves ideal for applications where flow control needs to be exact. Needle valves typically consist of a body, bonnet, needle stem, and a seat, with the needle valve being the central component that adjusts the opening for flow regulation.

How Does a Needle Valve Work?

Needle valves work by adjusting the position of the needle against the seat to regulate the flow of fluids or gases. Here’s how the process unfolds:

- Opening and Closing: When you turn the valve handle or actuator, it moves the needle up or down, either opening or closing the valve. The tapered needle fits tightly into the seat when fully closed, preventing flow. When lifted, it allows a controlled flow of the fluid or gas.

- Precise Flow Control: The long needle and its finely threaded adjustment mechanism allow for very small and controlled changes in the opening. This design makes the needle valve ideal for fine-tuning the flow, especially in applications requiring accurate dosing or regulation.

- Flow Rate Adjustment: As the needle moves within the valve body, the flow rate increases or decreases depending on how far the needle is raised. This gradual opening helps maintain stability and prevent sudden changes in flow, which could disrupt sensitive systems.

Applications of Needle Valves

Needle valves are used in a wide range of industries and applications, including:

- Oil and Gas Industry: Needle valves are often found in gas pipelines and fuel systems where precision is essential.

- Pharmaceuticals: In pharmaceutical manufacturing, they control the flow of liquids in highly sensitive processes.

- Water Treatment: Used for controlling the flow of chemicals in water treatment systems.

- Laboratories: Essential in experimental setups where precise flow control is critical for accurate results.

Conclusion

Needle valves are essential components that offer precision and control, particularly in systems where small adjustments to flow are necessary. Their ability to fine-tune the flow of gases and liquids makes them invaluable in industries such as pharmaceuticals, oil and gas, water treatment, and many more. Whether you need to regulate pressure, control fluid flow, or ensure the safety of your systems, understanding how a needle valve works will help you choose the right solution for your needs.

For more information, contact us at [email protected].