The alloy Monel is from the family of nickel alloys comprised mainly of nickel and copper with traces of iron, manganese, sulfur, and silicon. It can be hardened by the process of cold working. There are several varieties of Monel, each with its own set of benefits. Today, we will learn more about Alloy 400 variant i.e. Monel 400.

WHAT IS MONEL 400?

Monel 400 is a solid solution nickel alloy containing 52% to 67% of nickel and 28% to 34% of copper, which can be hardened through cold working only. It has high strength and toughness over a wide range of temperatures, as well as good corrosion resistance. This alloy is considered to be stronger than nickel alone, highly resistant to corrosion as mentioned earlier, and highly weldable. It is suited for a diverse range of applications ranging from gasoline tanks to electronic components.

WHAT ARE MONEL 400 INSTRUMENTATION TUBE FITTINGS?

Instrumentation tube fittings are commonly used with piping systems to enable pressure gauges, pressure switches, valves, flow monitors, and other essential instrumentation to be installed. These tube fittings can be used in advanced instrumentation to aid in automation, safety, and other aspects of piping system operation. Monel 400 instrumentation tube fittings are recommended for Sour Gas Applications Well Suited for Marine and General Chemical Processing Applications. Even in cyclic reducing conditions, Monel instrumentation tube fittings can be exposed to a variety of hydrochloric acids. The recommended temperature range for Monel 400 tubing material is -325°F to 800°F (-198°C to 425°C).

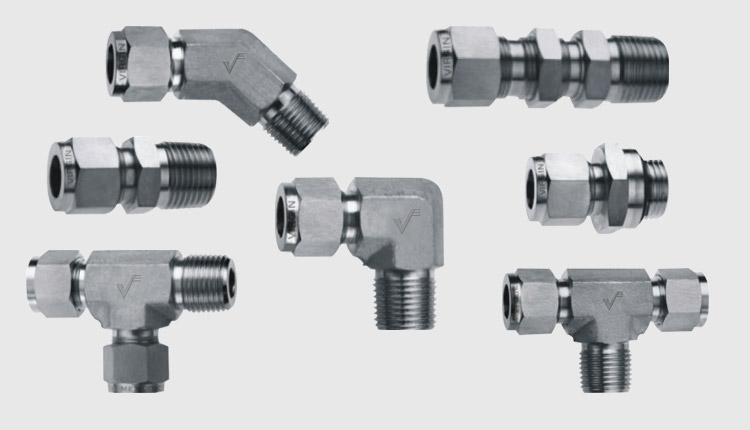

TYPES OF MONEL 400 TUBE FITTINGS

There exists a wide range of Monel 400 pipe fittings. Few of them are listed below;

- Elbows

- Connectors

- Caps

- Plugs

- Tees

- Union

- Reducer

- Adapters

- Ferrules

APPLICATIONS OF MONEL 400 TUBE FITTINGS

MONEL 400 is regarded as an excellent alloy for a wide range of industries and applications due to its good mechanical properties at low temperatures seawater resistance, alkali resistance, anti-corrosion properties, and strength. Mentioned below are some of it’s uses.

- Pump shafts, oil-well equipment, tools, doctor blades & scrapers, springs, valve trim, fasteners, and marine propeller shafts.

- Marine components like marine fixtures, fittings, pumps, valves and even piping systems.

- Chemical and hydrocarbon processing apparatus.

- Condensers, pumps, shafts, fittings and heat exchangers.

- Fittings to Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy & Shipbuilding Industries.

- Used to make specs frames, musical equipment, and aerospace-related products.