- Home

- Products

- Condensate Pots

- Alloy 20 Condensate Pots

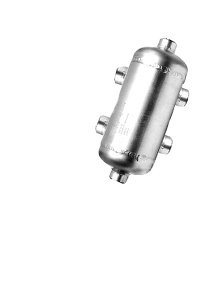

Alloy 20 Condensate Pots

Alloy 20 condensate pots flow liquid gases, including steam, between instruments or containers. These condensate pots are also called seal pots. Its main aim is to control the condensed liquid, which is called condensate pots. With the use of these condensate pots, the damage to the meter system can be easily prevented. Today, The product is used in many industrial applications and with the help of this product, the liquid content levels can be kept constant in the pressure transmitters.

Virgin engineers offered Alloy 20 condensate pots to the buyers in custom-made and standard specifications. Thus, they are available to buyers of different sizes, lengths, schedules, working pressures, standards, etc. The product is provided at market-leading rates to global buyers. The industry also provides very good sales after-sales and value-added services.

Alloy 20 is the nickel, chromium, and iron austenitic superalloy with an addition of other alloying elements like molybdenum and copper that provides resistance to pitting, hostile environment and crevice corrosion. This alloy is stabilised by columbium to reduce carbide precipitation during welding. This alloy falls between the nickel and stainless steel categories as it has both alloy features. Alloy 20 is developed to have maximum resistance to acid attack and provides good resistance to stress corrosion cracking.

It also offers corrosion resistance to sulfuric acid and chloride stress corrosion cracking. This alloy has very good mechanical properties at both elevated and ambient temperatures.

The manufacturing of alloy 20 condensate pots is done with the help of high-quality alloy sourced from reliable market vendors. The pots are designed under the strict guidance of professional experts who possess good knowledge of the better quality of product development. It is created per set manufacturing norms and international/national product quality standards using the latest technology and all modern tools/machinery.

Material testing is performed in the manufacturing industry to check the quality of the produced product. The testing done on it is like a chemical test, mechanical test, pitting resistance test, hardness test, etc.

Many important documents are provided to the buyers, such as the raw material test report, material traceability report, packaging list, guarantee letter, certificate of origin, commercial invoice, and NABL-approved lab test report. All these documents clear doubts about product quality.

Test certifications, such as mill test certificates per EN 10204/3.1B, are also offered to esteemed patrons. The other test certifications provided are a 100% radiography test report, third-party test report, buyers report, and raw material certificate.

Proper packaging of Alloy 20 condensate pots is conducted during product shipment to ensure safety at the time of delivery. The packaging is done in plywood cases and carton boxes. Customized packaging is also made to meet clients' needs.

Specification

Size

2", 3", 4", 6" & Larger size

End Connections

NPT

Pipe Schedule

40, 80, 160, XXS Seamless Steel

Length

8”, 10” & 12" & Larger size

Working Pressure

6000 PSIG(41.34 MPa)

Thread Connections

NPT as per ANSI B1.20.1,Socket weld as per ANSI B16.11, Butt weld as per ANSI B16.9

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy 20 | 2.4660 | N08020 |

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi - 35,000, MPa - 241 | 30 % |

Products

Condensate Pots 2 Ports

Condensate Pots 3 Ports Type 1

Condensate Pots 3 Ports Type 2

Condensate Pots 4 Ports Type 1

Condensate Pots 4 Ports Type 2

Condensate Pots 4 Ports Type 3

Condensate Pots 6 Ports

Condensate Seal Pots

Quality Assurance

Alloy N08020 Condensate Pots are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Alloy 20 Condensate Pots are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

alloy 20 condensate pot 4 ports type 1 manufacturer in mumbai, buy high quality alloy 20 condensate pots, alloy 20 condensate pots standards, alloy 20 condensate pots cp1 series, alloy 20 condensing chamber, alloy 20 parker condensate pots, alloy 20 fabricated condensate pots size, alloy 20 condensing pots stockholder, alloy 20 condensate seal pots traders, carpenter 20 air header, alloy 20 seal pots stockists , alloy 20 condensate pot 3 ports type 1 size, incoloy alloy 20 condensate pots price, carpenter 20cb-3® condensate pot 6 ports distributors, alloy 20 condensate pots 2 ports, alloy 20 condensate pot 4 ports type 1, alloy 20 seal chambers, parker carpenter 20cb-3 condensate pots grade 20, alloy 20 condensate pot 3 ports type 2 dealers, incoloy® alloy 20 swagelok condensate pots, carpenter 20 seal pots, alloy 20 condensate pot 3 ports type 3 india, alloy 20 condensate pots types.

© Copyright | Virgin Engineers 2021. All Right Reserved.