- Home

- Products

- Forged Steel Valves

- Duplex S32750 / S32760 Forged Steel Valves

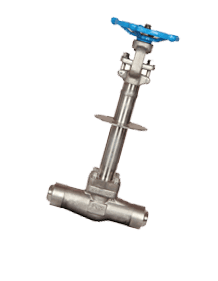

Super Duplex Steel S32750 / S32760 Forged Valves

Super Duplex Steel S32750 Forged Steel Valves, Super Duplex Stainless Steel S32760 Forged Valves, S32750 / S32760 Forged Steel Valves, S32750 Super Duplex Steel Forged Valves Suppliers, S32750 Forged Steel Valves, DIN 1.4410 Forged Steel Valves, Super Super Duplex 2507 Forged Steel Valves Manufacturers in Mumbai, India.

Virgin Engineers is leading manufacturer; supplier and stockholder of the very good quality of Super Duplex Steel S32750 S32760 Forged Steel Valves. It is designed as per set international as well as national product quality standards. This thus assures both reliability as well as durability of the product. No doubt the super duplex structure of UNS S32760 is combining impact strength and high tensile strength with the low coefficient of thermal expansion and also with thermal conductivity.

Also, the super duplex structure of S32750 valves is offering very good chloride stress corrosion cracking resistance. These attributes of the super duplex are making it an ideal choice for mechanical and structural components.

We are being customer ambitious offering the product to the buyers at standard specifications that vary in standards, rating, sizes and end connections. Also, they on the demands of buyers are providing it at custom-made specifications.

Super Duplex S32750 / S32760 Forged Steel Gate Valve, Super Duplex Stainless Steel S32750 Forged Globe Valves, Super Duplex S32760 Forged Steel Y-PATTERN Valves Exporters, Super Duplex Steel S32750 Forged Steel Integral Flanged End Valves, S32750/S32760 Super Duplex Forged Valves, Super Duplex Steel S32750 / S32760 Forged Valve, Super Duplex Steel S32750 / S32760 Forged Valves, Super Duplex 2507 Forged Steel Check Valves Supplier in Mumbai, India.

Super Duplex Stainless Steel S32760 Welded Bonnet Forged Valves, Super Duplex Steel S32750 Forged Steel Bolted Bonnet Valves, Super Duplex Steel S32750 / S32760 Flanged End Valve, Duplex S32760 Cryogenic Valve, Super Duplex 2507 Forged Steel Valves, Super Duplex S32750 Bellow Sealed Valve.

This super duplex stainless steel alloy is developed for offering properties like pitting resistance, high tensile strength, erosion corrosion, stress corrosion cracking, crevice corrosion, strong weldability, and corrosion fatigue. The content of molybdenum and chromium alloying elements in the super duplex is making it very well resistant to the uniform corrosion by the organic acids that include acetic acid and formic acid. Super duplex is also offering very good resistance to the inorganic acids particularly containing chlorides. Moreover, it can be exposed to higher temperatures.

The manufacturing of the Super Duplex Steel S32750 S32760 forged steel valves begins up by using the very good quality of raw substances. To deliver the superior quality of valves to the buyers the manufacturing of it begins up under the strict guidance of professional experts in compliance with modern technology and contemporary tools. The development of it is done exactly as per set manufacturing norms and product quality standards.

The testing of the product in the manufacturing industry is conducted by the experts to check the product quality. The tests done are like mechanical test, chemical test, hardness test, pitting resistance test, positive material identification test, intergranular corrosion test, etc.

To the buyers the test certifications are offered is including manufacturer test certifications in accordance with EN 10204/3.1B. Also, the other test certifications offered are like 100% radiography test report, third-party inspection report, buyers report and raw material certificate.

The documents copy are also along with the product is offered to the buyers that are including raw material test report, quality assurance plan, packaging list, guarantee letter. Also more documents like heat treatment chart, NABL approved lab test report, commercial invoice, fumigation certificate, etc is offered.

Packaging: When comes to the shipping of the Super Duplex Steel S32750 S32760 forged steel valves the packaging of these forged steel valves is done by using the wooden boxes and carton boxes. Also to make sure that while shipping the product doesn’t get harm, it is wrapped into polypropylene sheets.

Specification

End Connections

Screwed / Socket Weld / Butt Weld End

Face To Face

ANSI B 16.10

Butt Weld End

ANSI B 16.25

Working Pressure

800# / 1500#

Socket Weld End

ANSI B 16.11

Screwed End

ANSI B 1.20.1(BSP/NPT)

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| 7.8 | 0.281 | 1350 | 2460 |

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve

Forged Bellow Sealed Valve

Quality Assurance

Super Duplex Steel S32750 / S32760 Forged Steel Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Super Duplex Steel S32750/S32760 Forged Steel Valves are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel s32750 forged steel pressure seal bonnet valves distributors, super duplex s32750 / s32760 bolted bonnet forged gate valves, super duplex steel s32750 forged steel valves standards, super duplex steel s32760 pressure seal bonnet forged valves india, super duplex stainless steel s32750 socket welded forged steel valves, parker super duplex stainless steel forged valves grade s32750/s32760, super duplex 2507 forged gate valves, super duplex s32760 forged steel valves price, super duplex s32760 forged steel valves pressure sealed bonnet, super duplex s32750 bolted bonnet forged steel valves size, super duplex s32750 / s32760 flanged end globe valves stockists, super duplex steel s32750 flanged end check valves manufacturer in mumbai, super duplex steel s32750/s32760 forged steel valves types, super duplex steel s32760 forged seal welded valves , super duplex steel s32760 Forged valves, super duplex 2507 welded bonnet globe valves stockholder, super duplex steel s32760 flanged end gate valves dealers, buy high quality super duplex stainless steel s32760 forged steel valves, super duplex s32750 / s32760 parker forged steel valves, super duplex s32750 forged steel valves welded bonnet design, super duplex 2507 screwed forged steel valves traders, super duplex steel s32750 swagelok forged steel valves, super duplex steel s32750 forged steel globe valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.