- Home

- Products

- Valves

- Manifold Valves

- Hastelloy C22 Manifold Valves

Hastelloy C22 Manifold Valves

Hastelloy C22 3 - Way Manifold Valves, Hastelloy C22 5 Way Manifold Valves Suppliers, UNS N06022 Manifold Valves, DIN 2.4602 Manifold Valve in, Hastelloy Alloy C22 Valve Manifold, Alloy C22 2 Way Manifold Valve, Hastelloy C22 Instrument Manifold Valves Manufacturers in Mumbai, India.

Virgin Engineers stocks all type of Hastelloy grades and engaged in manufacturing of Hastelloy C22 Manifold Valves. We are equipped with large processing industry and storage facility where we perform a production of valves in various specifications, designations, standards, pressure ratings, and sizes. We draw the manifold valves in altered dimensions for multiple types of fittings, so the customers can get their respective type of valves as per their suitability. We are supplying products to the customers so customers can get only high quality products at reasonable rates.

Hastelloy is made up of the high amount of the chromium content that offers improved resistance to oxidization. Also, it has alloying elements that offer excellent service to the moderate to reducing environments. It also has some amount of nickel that adds workability in wet chlorine environments. These valves can be exposed in higher concentration blend of organic and inorganic compounds. These valves have great performance in the chemical reduction environments opposing pitting and crevice corrosion. Moreover, it performs well in stress corrosion cracking environments.

Hastelloy C22 H Series Manifold Valves, Hastelloy C22 Instrumentation Manifold Valves, Hastelloy C22 Remote-Mount, C22 Bellows Sealed Manifolds, Hastelloy C22 R - Type Manifold Valve, Hastelloy C22 Double Block Bleed Valves, Hastelloy Alloy C22 Three Way T- Type Manifold Valves, Hastelloy Alloy C22 Hydraulic Manifold, Hastelloy C22 Block and Bleed Valves.

Hastelloy Alloy C22 Direct-Mount Manifolds Exporters, Hastelloy C22 Remote-Mount Manifold Valve Supplier, Hastelloy C22 2 Valve Manifold, Hastelloy C22 3 Valve Manifold, Hastelloy C22 5 Valves Manifolds, Hastelloy Alloy C22 Valve Manifold in Supplier Mumbai, India.

Technical resources:

Our workforce is dedicated to providing possible expertise in manufacturing in regards to client’s requirements. We also provide some referrals such as manuals and credentials to the customers as a quality proof. We provide some guides to customers those are specification guide, quality assurance plan, welding guide, heat treatment charts. Furthermore documents are fumigation certificates, hardness details after heat treatment, stamping details, attested certificate by third-party entities and packaging details. Other credentials are Commercial invoice, MTC report, raw material test report, NABL test report, mill test report, and more.

What are the tests performed on Hastelloy C22 Manifold Valves?

We occupied the ISO certifications. We have the vow to keep our clients satisfied with our offered range of products. We are reactive to meet and exceed the product requirements of our customers. With stringent quality measure implementation, we are able to complete the production of valves with 100% surety. We perform different types of tests that include pressure tests, thermal stability test, PMI test, hardness test, micro test, mechanical test, destructive test, and pitting corrosion test. Other tests are intergranular corrosion test, macro test, ultrasonic test, chemical test, radiographic test, etc. Thus no poor quality of product is delivered to the buyers.

How did the valves pack?

We are responsive to assure to damage free products reach the customer's doorstep. We provide bulk offer deliveries within a week of order. Due to the fast and reliable transport service it is possible. Our packaging unit constantly monitored by professionals so there is no chance any faulty product gets dispatched. Hastelloy C22 Manifold Valves are packed in the heavy duty wooden cases, cartons and pallets with plastic end cap support. Moreover, it is coated by a thin film of plastic to prevent rusting.

However, customers can change the valves packing as per their suitability.

We offer bulk and small quantity of Hastelloy C22 Manifold Valves; one can get from different surface finish, tolerance limit, machining allowances for multiple types of applications.

Specification

ASTM

ASTM A494 / ASME SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | EN | JIS |

| Hastelloy C22 | N06022 | 2.4602 | - | NiCr21Mo14W | NW 6022 |

| C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000, MPa – 690 | Psi – 45000, MPa – 310 | 45 % |

Products

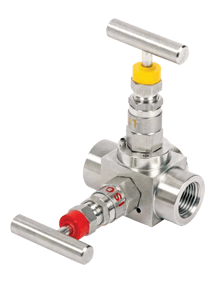

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

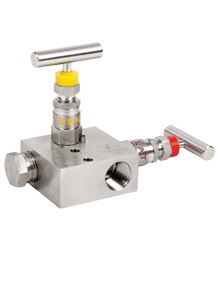

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

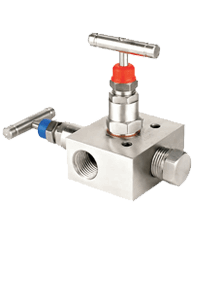

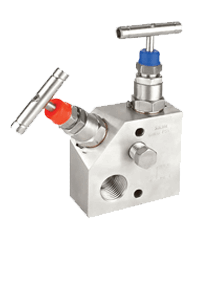

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Hastelloy N06022 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Hastelloy Alloy C22 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

hastelloy c22 manifold valves stockholder, hastelloy alloy c22 manifold 3 valves, hastelloy c22 two way manifold, hastelloy c22 manifold valves traders, buy high quality hastelloy c22 manifold valves, hastelloy c22 manifold valves types, hastelloy c22 manifold valve application, hastelloy c22 manifold valves price, hastelloy c22 manifold valves manufacturers in india, hastelloy c22 2 way manifold valve for pressure gauge, hastelloy c22 manifold valve size, hastelloy c22 valve remote mounted, hastelloy c22 manifold valves distributors, hastelloy c22 five way manifold, c22 manifold valves stockists, hastelloy c22 three way manifold price list, hastelloy c22 manifold hydraulic valves, hastelloy c22 manifold valves manufacturer in mumbai, hastelloy c22 manifold 2 valve t type manifold valve, c22 grade hastelloy manifold valve dealers, hastelloy c22 3 valve direct mounted, c22 hastelloy alloy types of manifold valves, hastelloy c22 manifold mounted ball valves.

© Copyright | Virgin Engineers 2025. All Right Reserved.