- Home

- Products

- Instrumentation Tube Fittings

- Hastelloy C276 Instrumentation Tube Fittings

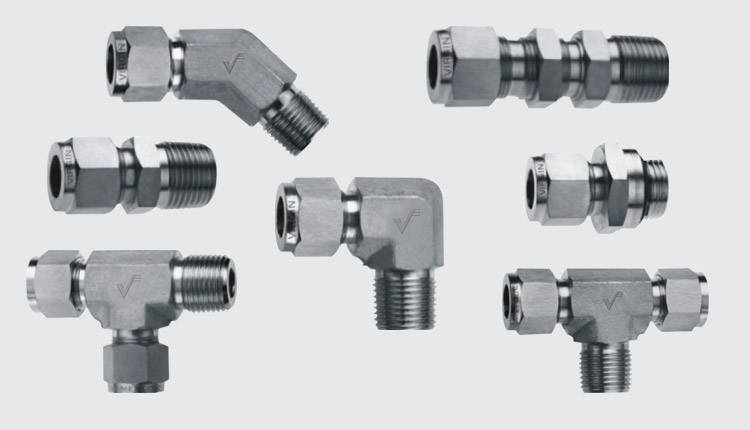

Hastelloy C276 Instrumentation Tube Fittings

Hastelloy Alloy C276 Double Ferrule Tube Fittings, Hastelloy C276 Compression Tube Fittings, Hastelloy C276 Ferrule Fittings Manufacturers, DIN 2.4819 Instrumentation Tube Fittings, Hastelloy® C276 Single Ferrule Fittings, Hastelloy C276 Instrumentation Fittings Suppliers, UNS N10276 Instrumentation Tube Fittings, Hastelloy C276 Tube Fittings Manufacturers in Mumbai, India.

Virgin engineers are a company dedicated to produce and sell the industrial Hastelloy C276 Instrumentation Tube Fittings. These instrumentation tube fittings are available in various designations, standards, specifications, and custom dimensions also as per the specific requirements of customers. We facilitate customer feedback service to assist customers in choosing the right tube fittings as per their application requirements. These are available in different treated surface and tolerance limits one can get from us.

It is a nickel, chromium and molybdenum superalloy with an addition of tungsten. It is developed to have excellent corrosion resistance in a wide range of severing engineering applications. It has the higher molybdenum and nickel content that makes it resistance to crevice and pitting corrosion in reducing environments while chromium carries resistance to oxidizing environments. This alloy has the ability to form grain boundary precipitation. This makes it suitable for various chemical processing application the weld affected zones. It has different variations in the Hastelloy grade, far the most widely used. It is widely used in the most critical applications in the chemical processing, industrial or municipal waste treatment, and more.

Hastelloy C276 Male Branch Tee, Hastelloy C276 Male Run Tee Exporters, Hastelloy C276 Male Connector, Hastelloy C276 Bulk Head Female Connector, Alloy C276 Bulk Head Male Connector, Hastelloy Grade C276 Female Connector, Hastelloy C276 Female Elbow, Hastelloy C276 Male Elbow Supplier in Mumbai, India.

Hastelloy C276 Female Branch Tee Hastelloy® C276 NPT Male Adapters., Hastelloy C276 Union Cross, Hastelloy C276 Reducer Union, Hastelloy C276 Bulk Head Union, Hastelloy C276 Female Run Tee, Hastelloy C276 Front Ferrule, Hastelloy C276 BSPP Plugs, Hastelloy Alloy C276 BSPT Couplings, Hastelloy C276 Reducer Port Connector – RPC

Resistance ability of Hastelloy C276 Instrumentation Tube Fittings:

It is considered one of the most versatile corrosion resistances. It exhibits great resistance in a wide range of chemical processing environments including cupric chlorides and ferrites. Moreover, these can offer service in environments having hot contaminated organic, inorganic compounds, chlorine, formic, acetic acids, acetic anhydride, seawater, brine, hypochlorite, and chlorine dioxide solutions. Additionally, it resists sensitization in the weld heat affected zone.

What are the characteristics of Hastelloy C276 Instrumentation Tube Fittings?

It has excellent corrosion resistance in reducing environments. It has brilliant resistance to strong solutions in oxidizing salts such as cupric and ferric chlorides. It has higher molybdenum and nickel content that provides excellent resistance in the reducing environments. It has lower carbon content that reduces the concern of grain boundary precipitation while induced in the welding operations. This maintains resistance to corrosion in the heat affected zone. It has local corrosion such as crevice and pitting corrosion. It is one of the few alloys that withstand in corrosive effects of wet chlorine gas, chlorine dioxide, and hypochlorite.

Tests performed on instrumentation tubes fittings:

Those are intergranular corrosion test, positive material test, tensile test, chemical test, macro test, ultrasonic test, and pitting corrosion test. Other tests are a radiographic test, hardness test, micro test, mechanical test, pressure test, macro test, compression test, etc.

Documentation reports offered by us:

Those are specification guide, welding guide, packaging details, MTC certificates, product invoice, attested certificate by suppliers, fumigation certificates, national board approval lab (NBAL) test report, and guarantee letter. Other reports are raw material test report, mill test report, quality assurance plan, heat treatment charts, stamping details, and more.

Packaging of the product-

Hastelloy C276 Instrumentation Tube Fittings are delivered in the prominent packing to delivering flawless products. It is thus packed into wooden cases and carton boxes for safer and damage free shipping and as per clients needs.

Specification

Size Range

1/16” 1/2” & 1.5MM to 38.1MM

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

| Hastelloy C276 | N10276 | 2.4819 | - | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

| C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000, MPa – 790 | Psi – 52,000, MPa – 355 | 40 % |

Products

Male Connector NPT-M

Male Connector BSP-M

Bulk Head Male Connector BMC

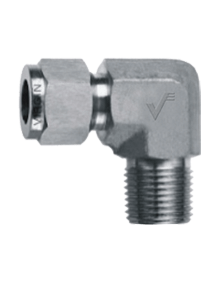

Male Elbow ME

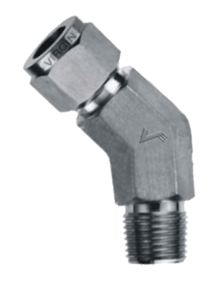

45° Male Elbow 45ME

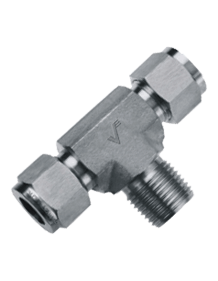

Male Branch Tee MBT

Male Run Tee MRT

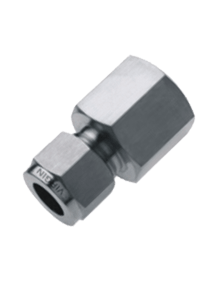

Female Connector FC

Bulk Head Female Connector BFC

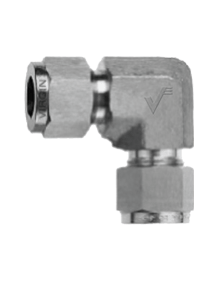

Female Elbow FE

Female Run Tee FRT

Female Branch Tee FBT

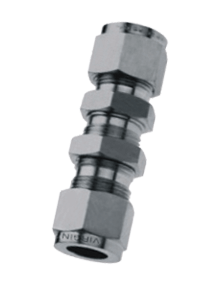

Union U

Reducer Union RU

Bulk Head Union BU

Union Elbow UE

Union Tee UT

Union Cross UC

Reducer R

Bulk Head Reducer BR

Port Connector PC

Male Adapter MA

Female Adapter FA

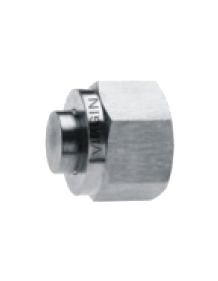

Cap TC

Plug (Port Ends) Tp

Tube Socket Weld Union TSWU

Male Pipe Weld Connector MPWC

Tube Socket Weld Elbow TSWE

Male Pipe Weld Elbow MPWE

Back Ferrule BF

Front Ferrule FF

Popular Searches

hastelloy c276 tylok instrumentation fittings, hastelloy alloy c276 instrument tube fittings, hastelloy c276 instrumentation tube fittings manufacturer in mumbai, hastelloy c276 instrument tube size, hastelloy® c276 swagelok fittings, hastelloy® c276 instrument tubing standards, hastelloy® c276 instrumentation valves and fittings india, hastelloy c276 twin ferrule fittings distributors, hastelloy c276 instrument fitting size, buy high quality hastelloy c276 instrument tube fittings, hastelloy c276 instrumentation fittings stockholder, hastelloy c276 duolok tube fittings, hastelloy c276 instrument fitting standards, hastelloy c276 parker tubing, hastelloy alloy c276 ferrule fittings, hastelloy® c276 instrument fittings swagelok, hastelloy c276 tube fittings stockists, parker hastelloy tubing fittings grade c276, hastelloy c276 compression fittings dealers, hastelloy® c276 instrumentation tube fittings price, hastelloy c276 instrument tubing fittings traders, hastelloy c276 instrument fittings types.

© Copyright | Virgin Engineers 2021. All Right Reserved.