- Home

- Products

- Instrumentation Tube Fittings

- Incoloy Alloy 800 / 800H / 800HT Instrumentation Tube Fittings

Incoloy 800 / 800H / 800HT Instrumentation Tube Fittings

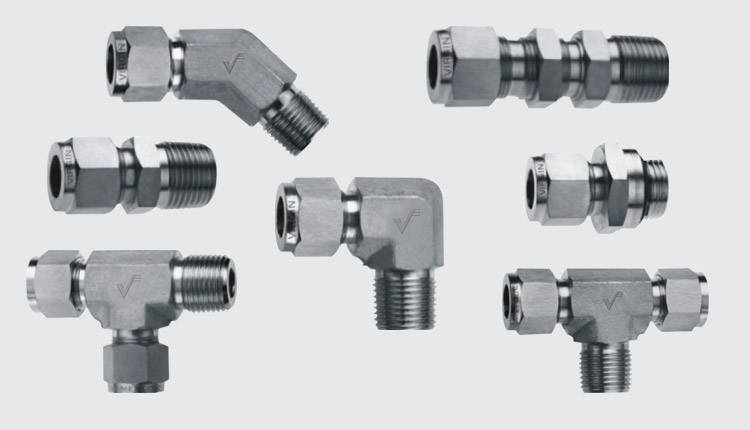

Incoloy® 800 / 800H / 800HT Single Ferrule Fittings, Incoloy 800H Ferrule Fittings, DIN 1.4876 Instrumentation Tube Fittings, UNS N08800 Instrumentation Tube Fittings, Incoloy 800HT Compression Tube Fittings, Alloy 800H Double Ferrule Tube Fittings, Incoloy 800HT Tube Fittings, Incoloy 800 Instrumentation Fittings Suppliers Manufacturers in Mumbai, India.

As a supplier, exporter and manufacturer we at Virgin engineer offer a superior quality range of Incoloy 800 / 800H / 800HT Instrumentation Tube Fittings to their esteem patrons. Our product finds its utility in various industrial applications. Being a reputed entity we manufacture the products as per the accepted norms and regulations of the industry. We adhere to furnish global standard product by using high-quality raw material acquired from the trusted dealers. Furthermore, our infrastructure is marked with the most highly advanced technology and state of art machinery through which we obtain finished standard and accurate dimensional product.

We have a team of qualified experts that aids to source out the international standard product. We provide the products in various shapes, size, length, dimensions, and thickness as per the requirements of the customers.

Incoloy 1.4958 / 1.4876 Instrumentation Tube Fittings, Incoloy 800HT Bulk Head Female Connector, Incoloy 1.4859 Instrumentation Tube Fittings, Incoloy 800H Male Branch Tee, Incoloy 800 Male Run Tee Exporters, Incoloy 800/800H/800HT Male Elbow, Incoloy 800 Female Elbow, Alloy 800HT Bulk Head Male Connector, Incoloy 800H Male Connector, Incoloy Grade 800HT Female Connector Supplier in Mumbai, India.

Incoloy 800 Front Ferrule, Incoloy 800H Reducer Union, Incoloy 800HT Female Run Tee, Incoloy Alloy N08811 Instrumentation Tube Fittings, UNS N08810 Instrumentation Tube Fittings, Incoloy 800 Reducer Port Connector – RPC, Incoloy 800H BSPP, Incoloy 800 Bulk Head Union, Incoloy 800HT Union Cross, Incoloy 800 Female Branch Tee, Alloy 800H BSPT Couplings Plugs Incoloy® 800HT NPT Male Adapters.

Incoloy 800 / 800H / 800HT Instrumentation Tube Fittings are nickel-chromium-iron alloy fittings that possess good resistance to corrosion and tensile strength. This grade of fittings excellently resists oxidation and carburization in high temperature exposures. The grade 800H/800HT both considers a higher level of carbon beside these the 800HT also constitute titanium and aluminium content in small margins. These grades of fittings are similar to each other and superior stress rupture properties. The presence of nickel ensures high resistant to both chloride stress corrosion cracking and embrittlement from precipitation of sigma phase.

The inclusion of high chromium and nickel alloy exhibits superb oxidation resistance. Furthermore, the fittings posses good corrosion resistance to many sulfur containing and acidic atmospheres.

This grade of instrumentation tube fittings are welded and formed through standard shop fabrication practices. Thus, the hot working of fittings is performed at the temperature range of 1740-2190 degree F whereas these are rapidly air cooled or water quenched. On the other hand, these are cold worked and facilitate good hardenability through it. With the most standard processes such as TIG, MIG, and MMA the fittings are readily welded. Furthermore, in annealed circumstances, these are excellently machined.

Testing & quality checking: The various stringent testing and inspections are executed at our manufacturing unit for checking and inspecting the workability and quality of the product. These tests are like a mechanical test, chemical analysis, flaring test, pitting resistance test, tensile strength test, hardness test and flattening test. Further other test is like radiography test, hydrostatic test, ultrasonic test, PMI test, third-party inspection, and IGC test.

Test certificates:We offer our customers reliable test certificate in accordance with EN 10204/3.1B. Such certificates are like raw material certificates, third-party inspection reports, and 100% radiography test reports.

Documentation:On the demands of the clients, we facilitate essential documentation along with the supply. These documents are like commercial invoice, fumigation certificates, quality assurance plan, heat treatment charts, material traceability records, NABL approved lab test reports and guarantee letters.

Packing & marking details: Maintaining the quality of the product is our prime concern, so to protect the products from severe harm during transit we make use of standard quality of packing material. Therefore we pack the products in wooden pallets, wooden boxes, and wooden cartons and in cases.

Specification

Size Range

1/16” 1/2” & 1.5MM to 38.1MM

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Incoloy 800 | N08800 | 1.4876 | Z8NC32-21 | X10NiCrAlTi32-20 | NCF 800 | NA 15 | ЭИ670 | XH32T |

| Incoloy 800H | N08810 | 1.4958 / 1.4876 | Z8NC33-21 | X5NiCrAlTi31-20 | NCF 800H | NA 15(H) | ЭИ670 | XH32T |

| Incoloy 800HT | N08811 | 1.4859 / 1.4876 | - | X8NiCrAlTi32-21 | NCF 800HT | NA 15(HT) | ЭИ670 | XH32T |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Ai | Ti |

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000, MPa – 520 | Psi – 30,000, MPa – 205 | 30 % |

Products

Male Connector NPT-M

Male Connector BSP-M

Bulk Head Male Connector BMC

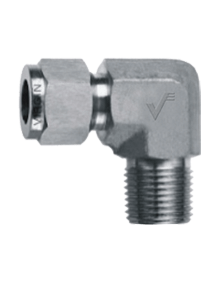

Male Elbow ME

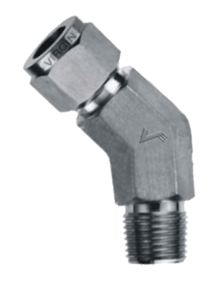

45° Male Elbow 45ME

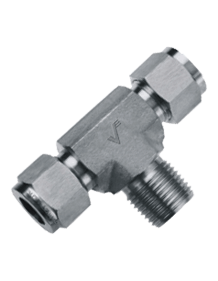

Male Branch Tee MBT

Male Run Tee MRT

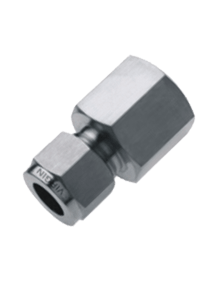

Female Connector FC

Bulk Head Female Connector BFC

Female Elbow FE

Female Run Tee FRT

Female Branch Tee FBT

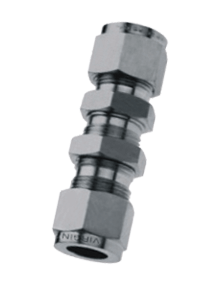

Union U

Reducer Union RU

Bulk Head Union BU

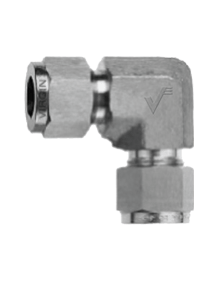

Union Elbow UE

Union Tee UT

Union Cross UC

Reducer R

Bulk Head Reducer BR

Port Connector PC

Male Adapter MA

Female Adapter FA

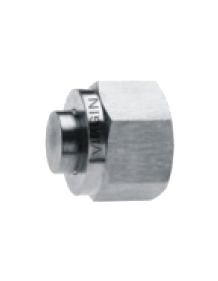

Cap TC

Plug (Port Ends) Tp

Tube Socket Weld Union TSWU

Male Pipe Weld Connector MPWC

Tube Socket Weld Elbow TSWE

Male Pipe Weld Elbow MPWE

Back Ferrule BF

Front Ferrule FF

Popular Searches

incoloy 800 / 800h / 800ht instrumentation tube fittings manufacturer in mumbai, incoloy 800 / 800h / 800ht parker tubing, incoloy® 800ht instrumentation tube fittings price, incoloy 800 tube fittings stockists, incoloy 800h instrument fitting standards, incoloy® 800ht instrumentation valves and fittings india, incoloy 800 instrument fitting size, incoloy® 800 instrument tubing standards, incoloy 800 twin ferrule fittings distributors, incoloy alloy 800h ferrule fittings, incoloy 800ht instrument tube size, incoloy 800 / 800h / 800ht instrumentation fittings stockholder, incoloy 800h instrumentation tube fittings, incoloy 800h duolok tube fittings, incoloy 800ht instrument tube fittings, parker incoloy tubing fittings grade 800, incoloy® 800 / 800h / 800ht swagelok fittings, incoloy 800h instrument fittings types, buy high quality incoloy 800ht instrument tube fittings, incoloy® 800 instrument fittings swagelok, incoloy 800h instrument tubing fittings traders, incoloy 800ht tylok instrumentation fittings, incoloy 800 / 800h / 800ht compression fittings dealers.

© Copyright | Virgin Engineers 2025. All Right Reserved.