- Home

- Products

- Condensate Pots

- Incoloy 825 Condensate Pots

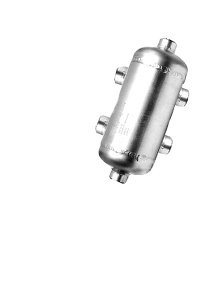

Incoloy 825 Condensate Pots

Grade 825 Incoloy Condensate Pots Suppliers, UNS N08825 Condensate Pots, Incoloy 825 Condensate Pots, DIN 2.4858 Condensate Pots, Alloy 825 Seal Pots Manufacturers in Mumbai, India.

Virgin engineers undertake the manufacturing of Incoloy 825 Condensate Pots. These condensate pots are designed for application in heavy gauge industries. A wide range of condensate pots is being made by us in various standards, designations, specifications, shapes, sizes, and altered dimensions. Each and every product made by us excels the international quality of standards.

With the presence of a large processing unit and latest machines, we are able to produce condensate pots in bulk orders with 100% dimensional accuracy. Because of the fast and reliable logistic service, our products got reached to customer destination on-time.

Any type of queries made by our customers regarding product and services can be resolved immediately.

Incoloy 825 Seal Pots, Alloy 825 2 Ports Condensate Pots, Incoloy Alloy 825 Condensate Pot Seal Pot, Incoloy Alloy 825 Seal Pots Exporters, Grade 825 Incoloy Condensate Seal Pots, Alloy 825 Condensation Pots, Incoloy Condensate Pots, Incoloy 825 DRIP Pots, Incoloy 825 Condensate Pots Supplier in Mumbai, India.

Incoloy 825 Condensate Pots, Incoloy 825 Condensate Seal Chambers, Incoloy Alloy 825 Seal Pots, Incoloy 825 Condensate Seal Pots, Alloy 825 Condensate Pots, Incoloy Alloy 825 Condensate Chamber.

Alloy 825 has cold and hot workability same to those standard austenitic stainless steel. All possible welding process can be induced for the welding process. All types of welding process such as TIG, MIG, arc, resistance and submerged welding process is associated with this grade. These are weldable with both without consumable. This grade has machinability approximately equivalent to standard austenitic stainless steel.

The machining process requires high-speed tool, super hard tool and a slow feed speed and adequate cut depth. The solution annealing process is normally performed at the temperature range between 930 deg C to 1030 deg C that is followed by rapid quenching with water.

It is a nickel, chromium, and iron base alloy with addition of copper, titanium, and molybdenum. The material composition is designed to provide exceptional resistance to corrosive environments. This grade possess properties same as its standard version. This grade has excellent resistance to oxidizing and reducing media. These condensate pots can be exposed to the environments having concern stress corrosion cracking, crevice and pitting corrosion. Especially, this grade is resistive to phosphoric and sulfuric acids.

Virgin engineers follow quality check measures to maintain and improve Incoloy 825 Condensate Pots quality and customer satisfaction. Each finished condensate pots are checked before packaging and inspected by in-house or third parties if the customer demands any special tests we perform it. To verify supply made products are up to the mark we perform a different type of tests. the tests are performed by us are thermal property test, chemical composition analysis, mechanical property test, compression test, pressure test, leakage test, hardness test, and pitting corrosion test.

The secondary tests are IGC test, radiographic test, tensile test, macro test, ultrasonic test, chemical test, positive material test, hydro test and more. The final inspection is made by third parties to assure the quality of products.

Specification

Size

2", 3", 4", 6" & Larger size

End Connections

NPT

Pipe Schedule

40, 80, 160, XXS Seamless Steel

Length

8”, 10” & 12" & Larger size

Working Pressure

6000 PSIG(41.34 MPa)

Thread Connections

NPT as per ANSI B1.20.1,Socket weld as per ANSI B16.11, Butt weld as per ANSI B16.9

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Incoloy 825 | 2.4858 | N08825 | ЭП703 | NFE30C20DUM | NCF 825 | NA 16 | NiCr21Mo | XH38BT |

| Grade | Ni | Cr | Fe | Al | Ti | C | Mn | Al | S | Si | Cu |

| Incoloy 825 | 38.0-46.0 | 19.5-23.5 | 22.0 min | 0.2 max | 6-1.2 | 0.05 max | 1.0 max | 0.2 max | 0.03 max | 0.5 max | 1.5-3.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1370-1400 ℃ | 550 | 200 | 30 % |

Products

Condensate Pots 2 Ports

Condensate Pots 3 Ports Type 1

Condensate Pots 3 Ports Type 2

Condensate Pots 4 Ports Type 1

Condensate Pots 4 Ports Type 2

Condensate Pots 4 Ports Type 3

Condensate Pots 6 Ports

Condensate Seal Pots

Quality Assurance

Incoloy N08825 Condensate Pots are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Incoloy 825 Condensate Pots are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 825 condensate pots standards, alloy 825 condensate pots cp1 series, inconel 825 condensate pot 3 ports type 2 dealers, inconel 825 condensate seal pots traders, inconel 825 condensate pots types, inconel 825 condensate pot 6 ports distributors, alloy 825 swagelok condensate pots, inconel 825 condensate pot 4 ports type 1 manufacturer in mumbai, alloy 825 condensing chamber, parker inconel condensate pots grade 825, inconel alloy 825 condensing pots stockholder, alloy 825 parker condensate pots, inconel alloy 825 fabricated condensate pots size, inconel 825 seal chambers, buy high quality inconel 825 condensate pots, inconel 825 condensate pot 3 ports type 3 india, inconel 825 seal pots, inconel 825 air header, inconel alloy 825 condensate pots 2 ports, alloy 825 condensate pot 3 ports type 1 size, inconel 825 condensate pot 4 ports type 1, nickel alloy 825 condensate pots price, inconel 825 seal pots stockists.

© Copyright | Virgin Engineers 2025. All Right Reserved.