- Home

- Products

- High Pressure Pipe Fittings

- Super Duplex S32750/S32760 High Pressure Pipe Fittings

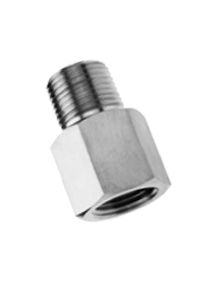

Super Duplex Steel S32750/S32760 High Pressure Pipe Fittings

UNS S32750/S32760 High Pressure Pipe Fittings, Super Duplex S32750 High Pressure Pipe Fittings Suppliers, DIN 1.4410 High Pressure Pipe Fittings, SAF 2507 Industrial High Pressure Pipe Fittings, Super Duplex Stainless Steel S32760 High Pressure Pipe Fittings Manufacturers in Mumbai, India.

Virgin engineers are the reputable dealer of high class high pressure pipe fittings of all ferrous and non-ferrous materials. Our industry now is leading on the top for being the best manufacturer, supplier, stockiest and exporter of the commendable quality of Super Duplex Steel S32750 / S32760 High Pressure Pipe Fittings. We are expanding inventory and sales through their sheer perseverance and innovations. Also, the potential of us lie into the business growth fueling through full assistance in the selection of the product and applications as well. To the national and international buyers, the product is delivered at wide ranges so that all applications desires can be very well fulfilled. The product to the buyers is offered at different standards, dimensions, types, classes, sizes, etc. It is delivered to the respective buyers at custom made specifications.

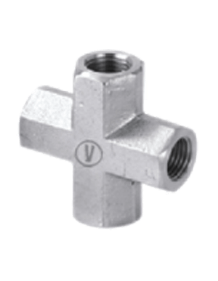

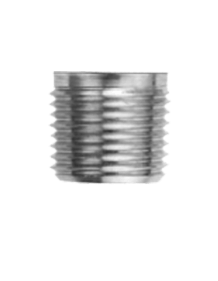

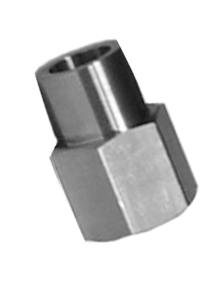

Super Duplex Steel S32750/S32760 Hex Reducing Nipple, Super Duplex SAF 2507 Reducing Bushing, Super Duplex Steel S32750/2507 Hex Coupling, Super Duplex Stainless Steel S32750 Hex Long Nipple Exporters, S32760 Super Duplex Steel Reducing Adapter Supplier in Mumbai, India.

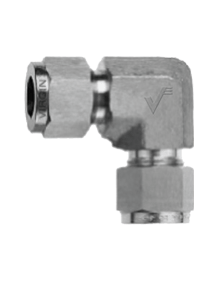

S32760 Super Duplex Steel Gauge Adapter, Super Duplex Stainless Steel S32750 Allen SAE Plug, Super Duplex S32760 Female Connector, Super Duplex Steel S32750 Union Elbow, Super Duplex S32760 Union Cross, Super Duplex Steel S32750 Male and Female Elbow, Super Duplex S32760 Elbow Reducing Street.

Alloy information you should know-

Super Duplex Steel S32750 / S32760 are the alloy that is mainly designed in order to possess high tensile strength. Also, the alloy is possessing very good resistance ability against corrosion fatigue, erosion corrosion, pitting, crevice corrosion, and stress corrosion cracking. Moreover, it is able to withstand strong weldability. Thus this alloy is found to be used in many industrial applications.

Manufacturing of the product-

The manufacturing of the Super Duplex S32750 / S32760 High Pressure Pipe Fittings is done by using the superior quality of alloy. The alloy that they are using is well tested in order to check the product quality. The entire production process is executed under the strict guidance of professional experts and they guide the workers at all level of the production process to fabricate the error-free quality of the product.

The use of latest technology and modern tools have helped the manufacturers to make 100% superior quality of same assuring smooth surface finishes and perfect dimensional accuracy. The fabrication of the product is done by mandatorily considering raw material quality standards and manufacturing guidelines.

Good qualities of the product-

No doubt the effectiveness in the product creation has led the high-pressure pipe fittings to offer excellent features. Some of them are high tensile strength, good weldability, long-lastingness, holds high pressure, withstand high temperature and easy to use. Also the same is having the ability to resist crevice corrosion, pitting, stress corrosion cracking, etc.

Testing-

At the industry, the testing of Super Duplex Stainless Steel S32750 / S32760 High Pressure Pipe Fitting is conducted to check product quality. The tests done are like positive material identification test, hardness test, intergranular corrosion test, pitting resistance test, mechanical test, chemical test, etc. other tests are destructive test, non-destructive test, leakage test, pressure line test, macro test, micro test, tensile test, thermal stability analysis and more.

Documenting-

To the buyers the documents offered are like heat treatment chart, quality assurance plan, packaging list, commercial invoice, guarantee letter, raw material test report, material traceability report, etc. The test certifications like mill test certifications as per EN 10204/3.1B, 100% radiography test report, third-party test report, raw material certificate, etc.

Specification

Types

High Pressure Pipe Fittings

End Connections :

NPT, BSP, & BSPT.

Size Range

1/16” to 2”

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

Products

Close Nipple

Hex Nipple

Hex Reducing Nipple

Hex Long Nipple

Reducing Adapter

Reducing Bushing

Hex Coupling

Hex Reducing Coupling

Elbow Female

Elbow Reducing Street

Male Elbow

45° Elbow Female

45° Elbow Street

Tee Female

Tee Street

Tee Branch

Tee Male

Cross Female

Union Ball Joint

Hex Female Cap

Hex Male Plug

Allen Plug

Hex SAE Plug

Allen SAE Plug

SAE Adapter

Hex Pipe Plug

Gauge Adapter

Male Connector

Female Elbow

Union Cross

Female Connector – FF

Union

Union Elbow

Male Adaptor NPT

BSPT Coupling

Quality Assurance

Super Duplex Steel S32750/S32760 High Pressure Pipe Fittings are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Super Duplex Stainless Steel S32750/S32760 High Pressure Pipe Fittings are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

saf 2507 high pressure pipe fitting, super duplex steel s32750/s32760 high pressure pipe fittings standards, super duplex s32750/2507 high pressure pipe fittings traders, super duplex steel s32750 elbow street price, super duplex stainless steel s32760 45° elbow street india, super duplex steel 2507 male elbow dealers, super duplex steel s32750 hex reducing nipple, super duplex s32760 close nipple, s32750 super duplex gauge adapter size, super duplex steel 2507/s32760 45° elbow female manufacturer in mumbai, super duplex steel s32750 hex nipple, super duplex steel s32760 tee female/street/branch/male distributors, super duplex steel 2507 elbow female, s32760 super duplex steel sae adapter, super duplex stainless steel s32750 male connector specification, super duplex s32760 allen plug, s32750 super duplex steel hex male plug and sae plug, super duplex steel s32760 hex pipe plug mechanical priperties, super duplex stainless steel hex long nipple grade s32750, s32760 super duplex adapter & reducing adapter size, super duplex steel s32750 hex reducing coupling size, s32760 super duplex cross female, super duplex steel s32750 reducing bushing types, buy high quality super duplex stainless steel s32750/2507 hex female cap, super duplex steel s32750 elbow reducing street stockists, super duplex steel s32750/s32760 high pressure pipe fittings stockholder, super duplex steel s32760 high pressure pipe fittings chemical composition, super duplex s32750 hex coupling.

© Copyright | Virgin Engineers 2025. All Right Reserved.