- Home

- Products

- Needle & Gauge Valves

- Super Duplex S32750 / S32760 Needle & Gauge Valves

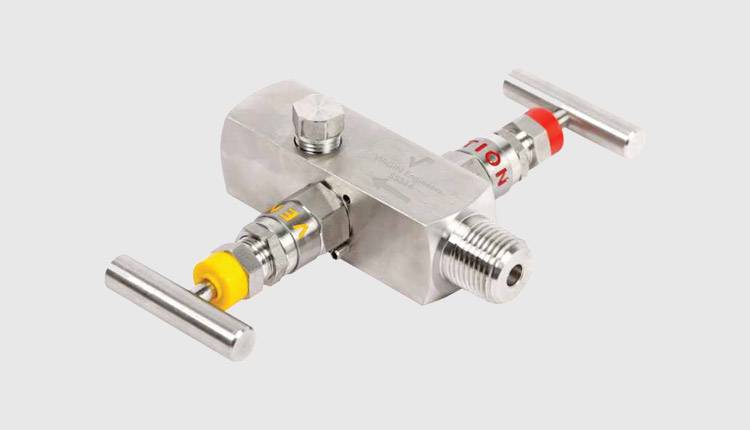

Super Duplex Steel S32750/S32760 Needle & Gauge Valves

SAF 2507 Super Duplex Steel Needle / Gauge Valves, Super Duplex Steel S32750/S32760 Industrial Needle & Gauge Valve, Super Duplex Steel S32750 Gauge Bleed Needle Valves Suppliers, Super Duplex Steel S32760 Needle and Gauge Valves, Super Duplex Steel S32760 Needle & Gauge Valves, Grade S32750 Super Duplex Steel Gauge Valves Manufacturers in Mumbai, India.

Needle & Gauge Valves comes in various designed and range in the market apart from these to choose the finest quality of valves to get it from the Virgin Engineers. The firm is one of the foremost and highly acclaimed manufacturer, exporter and supplier of Super Duplex Steel S32750 / S32760 Needle & Gauge Valves. The firm has achieved an authentic position in the industrial market by offering premium quality of product and value added services to them. Being a reputed organization we are completely committed towards our work. Therefore we have the great support of skilled employees and highly experience gained professionals that adhere to obtain a national and international standard product. Well talking about its manufacturing process we procure the best quality of raw material from the authorized and reputed dealer of the industry. Moreover, we use innovative technologies and highly advance machinery to obtain durable and perfect size product. In order to satisfy and fulfill the desires of the customers, we offer them our products in custom-made length, size, grade and thickness as per their suitability.

S32760 Super Duplex Steel Multiport Gauge Valves, Super Duplex S32750 Gauge Vent Valves Exporters, Super Duplex Steel S32760 Hydraulic Needle Valve, SAF 2507 Parker Needle Valve, S32750 Super Duplex Screwed End Needle Valve Supplier in Mumbai, India.

Super Duplex Stainless Steel S32750/S32760 Gauge Valve, Super Duplex S32750 Integral Bonnet Needle Valve, Super Duplex Steel S32760 Forged Body Gauge Valve, SAF 2507 Needle and Gauge Valves, Super Duplex S32760 Needle Valve, Super Duplex Steel S32750 Autoclave Needle Valve, Super Duplex Stainless Steel S32750 Needle / Gauge Valves

Product details

Super Duplex Steel S32750 / S32760 Needle & Gauge Valves are austenitic-ferritic stainless steel alloy needle & gauge valves mainly utilized in high pressure and aggressive environments. The chemical composition of both grades involves chromium/ nickel and molybdenum content. These gauge valves & needle possess superior resistance to a broad range of media. The duplex microstructure ensures exception resistance to chloride stress corrosion cracking and higher strength. Furthermore, the bars have higher heat conductivity and low coefficient of thermal expansion than other steels that are suitable in working temperature range up to 300 degrees C.

Due to molybdenum and chromium content these grades of needle & gauge valves exhibit great resistance to uniform and local corrosion such as crevice and pitting in the seawater environment. Moreover, it also resists chloride containing atmospheres. These also possess great toughness, hardness, and mechanical properties at elevated temperatures

Testing & quality checking

To maintain the highest level of quality and durability of the product we monitor each and every material on different parameters. These tests are like a mechanical test, pitting resistance test, chemical analysis, hardness test, ultrasonic test, flaring test PMI test, flattening test and macro/micro test. Other more test are like tensile strength test, IGC test, radiography test, shell leakage test, hydrostatic test, temperature testing and many more.

Testing certificate

Test certificate such as raw material certificate, 100% radiography and third-party inspection reports are provided to the customers.

Documentations

We deliver the product with authentic documentation that comprises reliable information of the product. These documents are like raw material traceability records, fumigation certificate, NABL approved lab test report, quality assurance plan, heat treatment charts, commercial invoice and guarantee letters.

Packing details

We utilize high standard of packing material for product packaging which provides the product from any severe harm and scratches that mainly occur during transportation. The product is generally packed in wooden cartons, wooden boxes, wooden pallets, and wooden cases and in wooden crates.

Specification

Types

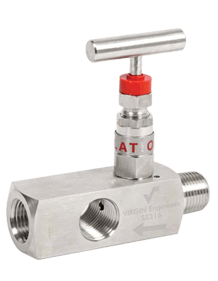

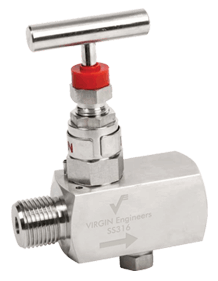

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design:

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Super Duplex Steel S32750/S32760 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Super Duplex Stainless Steel S32750/S32760 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

super duplex stainless steel s32750/s32760 hydraulic needle valve, super duplex s32750 block & bleed gauge valves, super duplex stainless steel s32760 gauge/needle valve traders, super duplex stainless steel steel s32760 gauge valve, s32750 super duplex high pressure gauge valve size, super duplex s32760 parker needle valve india, super duplex steel multiport gauge valves grade s32760, super duplex s32760 integral bonnet needle valve price, super duplex s32750 bonnet needle valves size, super duplex s32750/2507 gauge & needle valve stockholder, super duplex steel s32750 forged body gauge valve types, super duplex steel saf 2507 needle & gauge valve standards, super duplex s32750 screwed end needle valve stockists, buy high quality super duplex Steel s32760 needle and gauge valve, super duplex steel s32760 autoclave needle valve manufacturer in mumbai, super duplex s32750 gauge bleed needle valves, super duplex steel s32760 needle valve distributors, s32750 super duplex gauge valve, super duplex steel s32760 gauge vent valves, super duplex s32750 needle valve standards, super duplex Stainless steel s32750/2507 3 way needle valve dealers.

© Copyright | Virgin Engineers 2021. All Right Reserved.