- Home

- Products

- Needle & Gauge Valves

- Alloy 20 Needle & Gauge Valves

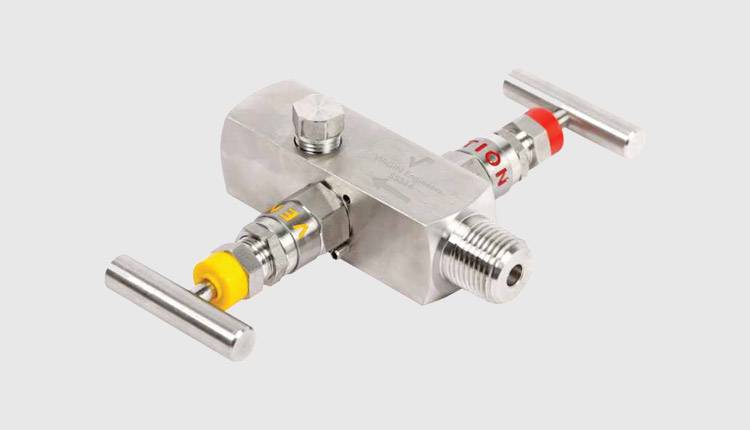

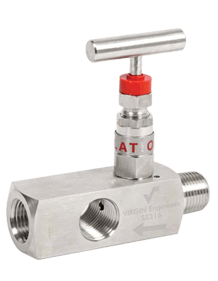

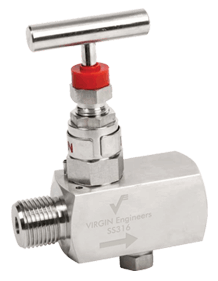

Alloy 20 Needle & Gauge Valves

Alloy 20 Needle / Gauge Valves, Alloy 20 CB3 Needle and Gauge Valves, Alloy 20 Gauge Bleed Needle Valves Suppliers, Carpenter 20 Needle & Gauge Valves, Incoloy 20 Gauge Valves, Alloy 20 Industrial Needle & Gauge Valve Manufacturers in Mumbai, India.

Virgin Engineers is a trusted manufacturer and supplier of Alloy 20 needle and gauge valves in India, providing high-quality solutions that deliver long-lasting performance in highly corrosive environments. These valves are made using Alloy 20 (UNS N08020), a nickel-iron-chromium alloy that offers excellent resistance to sulfuric acid, nitric acid, phosphoric acid, and chloride-containing media. Often considered a superior alternative to stainless steel 316, Alloy 20 is known for its ability to withstand pitting, crevice corrosion, and stress corrosion cracking. This capability makes it a preferred choice across industries such as chemical processing, petrochemicals, pharmaceuticals, food and beverage, marine, and paper and pulp.

The Alloy 20 needle valves manufactured by Virgin Engineers are used for accurate regulation of fluid flow in instrumentation and control lines. On the other hand, the gauge valves are used to isolate pressure gauges, transmitters, and other instruments, ensuring safe and accurate readings without compromising the integrity of the system. Both valve types are designed to perform well under high pressure and elevated temperatures, even when exposed to corrosive liquids or gases.

Alloy 20 Hydraulic Needle Valve, Alloy 20 CB3 Multiport Gauge Valves, Alloy 20 Gauge Vent Valves Exporters, Alloy 20 Parker Needle Valve, Carpenter 20 Screwed End Needle Valve Supplier in Mumbai, India.

Incoloy 20 Needle / Gauge Valves, Alloy 20 Forged Body Gauge Valve, Alloy 20 CB3 Autoclave Needle Valve, Alloy 20 Integral Bonnet Needle Valve, Alloy 20 Gauge Valve, Alloy 20 Needle Valve, Alloy 20 Needle and Gauge Valves.

Our Alloy 20 gauge valves are available in sizes ranging from ¼” to 1”, with pressure ratings up to 6000 PSI. These valves can be supplied with various end connections, including NPT, BSPT, BSPP, socket weld, flanged ends, and double ferrule compression fittings. To ensure reliable sealing and long-term operation, each valve is built with high-grade PTFE or graphite packing. We offer design options including integral bonnet, bar stock body, and forged body configurations to meet different application needs.

Each valve is manufactured in accordance with international standards such as ASME, ASTM, and ANSI. Quality assurance is central to our production process, and every unit undergoes pressure and leakage tests before dispatch. We also provide complete documentation, including EN 10204 3.1 Mill Test Certificates and third-party inspection reports, when required by the client.

Virgin Engineers continues to serve a wide customer base with its precision-engineered Alloy 20 needle and gauge valves, offering both durability and excellent corrosion resistance. With strong technical capabilities and a customer-first approach, we ensure prompt delivery, export-grade packaging, and full support for both standard and custom valve requirements worldwide.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design:

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS | EN | AFNOR |

| Alloy 20 | 2.4660 | N08020 | NiCr20CuMo | Z2NCUD31-20AZ |

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi - 35,000, MPa - 241 | 30 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Alloy 20 UNS N08020 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Alloy 20 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

alloy 20 needle & gauge valve standards, carpenter 20 needle valve standards, alloy 20 cb3 gauge valve, incoloy 20 gauge bleed needle valves, alloy 20 cb3 gauge vent valves, alloy 20 multiport gauge valves, alloy 20 high pressure gauge valve size, alloy 20 cb3 forged body gauge valve types, alloy 20 block & bleed gauge valves, alloy 20 bonnet needle valves size, alloy 20 hydraulic needle valve, alloy 20 integral bonnet needle valve price, incoloy 20 cb3 screwed end needle valve stockists, alloy 20 3 way needle valve dealers, alloy 20 autoclave needle valve manufacturer in mumbai, alloy 20 parker needle valve india, alloy 20 cb3 needle valve distributors, incoloy 20 gauge valve, alloy 20 gauge & needle valve stockholder, buy high quality incoloy 20 needle and gauge valve, alloy 20 gauge/needle valve traders.

© Copyright | Virgin Engineers 2025. All Right Reserved.