- Home

- Products

- Instrumentation Tube Fittings

- SS 304L Instrumentation Tube Fittings

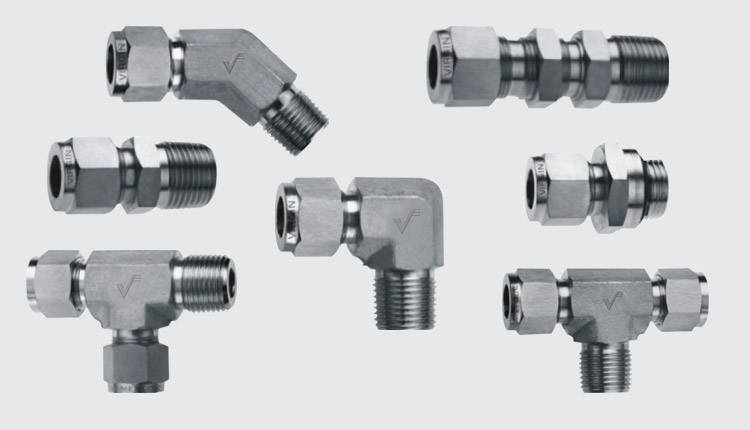

SS 304L Instrumentation Tube Fittings

SS 304L Compression Tube Fittings, UNS S30403 Instrumentation Tube Fittings, SS 304L Tube Fittings Suppliers, DIN 1.4306/1.4307 Instrumentation Tube Fittings, Stainless Steel 304L Ferrule Fittings, Stainless Steel 304L Instrumentation Fittings, Grade 304L Stainless Steel Single Ferrule Fittings, SS 304L Double Ferrule Tube Fittings Manufacturers in Mumbai, India.

Instrumentation tube fittings are basically formed to offer strong leak-proof connections to various applications. Similarly, these are used for joining various unions together to form a good tubing system. Therefore these are tube fitting offers a reliable and fast association in process and analytical instrumentation systems. In addition to these has good capability to withstand in extreme temperatures and high pressures circumstances. Meanwhile, these fittings deliver outstanding leak-tight seal, easy to install and are easily reassemble and disassemble. In the huge market, there are many types and range of instrumentation tube fittings are available but if one wants to purchase the best range of tube fitting then the client must consider the Stainless Steel 304L Instrumentation Tube Fittings. This alloy of tube fitting is the best range that is highly appreciated for its unmatched qualities and attributes. The fittings feature superior dimensional accuracy, robust design, and precise finished and superior corrosion resistance properties.

SS 304L Bulk Head Male Connector, SS 304L Male Elbow, SS 304L Female Elbow , SS 304L Male Run Tee, SS 304L Male Branch Tee Exporters, SUS 304L Bulk Head Female Connector, Grade 304L SS Female Connector, Stainless Steel 304L Male Connector Supplier in Mumbai, India.

SS 304L BSPP Plugs, SS 304L Female Branch Tee, SS 304L BSPT Couplings, SS 304L Front Ferrule, AISI 304L NPT Male Adapters, Stainless Steel 304L Bulk Head Union, SS 304L Reducer Port Connector – RPC, SS 304L Reducer Union, SS 304L Union Cross, SS 304L Female Run Tee.

Company details

Virgin Engineers is one of the acclaimed and dominant firms in the market that is pretty much engrossed in manufacturing, supplying and exporting a vast range of Stainless Steel 304L Instrumentation Tube Fittings. all over the world. We as a reputed firm always focus on the quality of the product. With the support of highly qualified professionals and employees, we are committed towards our manufacturing process in order to achieve

a national and international standard product. In addition to this, we procure the best quality of raw material from the authorized dealer that is well tested and inspected by our quality checkers. Furthermore, we equipped

the most recent technologies and highly advanced machinery for obtaining the top-notch finished and standard size product. We offer our quality range product in a vast array of shapes, size, grade, dimension, length and

size as per the precise demands and requirement of the customers.

In addition to this, we procure the best quality of raw material from the authorized dealer that is well tested and inspected by our quality checkers. Furthermore, we equipped the most recent technologies and highly advanced machinery for obtaining the top-notch finished and standard size product. We offer our quality range product in a vast array of shapes, size, grade, dimension, length and size as per the precise demands and requirement of the customers.

Product description

Stainless Steel 304L Instrumentation Tube Fittings are the most versatile extensively used austenitic stainless steel tube fittings. These include 8% of nickel and

18% of chromium content adding up with low carbon content. This alloy of fitting exhibits superior resistance to corrosion in many environments, furthermore, these exhibits good resistance to the crevice and pitting corrosion

in environments containing chlorides. In addition to these often exhibit resistance to stress corrosion cracking above 60 degrees C. In welded conditions the tubing possesses good resistance to intergranular corrosion.

At cryogenic temperatures, the tube fittings feature superior tensile strength, toughness, and hardness. The presence of low carbon ensures to avoid carbide precipitation in the heat affected region. The tubes are mainly non-magnetic but become slightly magnetic when get cold worked. On the other hand, these are not hardened by heat treatment, therefore these are solution treated and annealed and are rapidly cooled. The fittings have good mechanical, drawing, spinning and forming properties that can withstand in high temperatures circumstances and offers long term services.

Testing details

To obtain an error-free and flawless quality product these are well examined and tested under the control of quality checkers. These tests are like hardness test, pitting resistance test,

mechanical test, PMI test and many more.

Specification

Size Range

1/16” 1/2” & 1.5MM to 38.1MM

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | 2CrNi18-9 / X2CrNi19-11 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | - | 8 – 13 | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Male Connector NPT-M

Male Connector BSP-M

Bulk Head Male Connector BMC

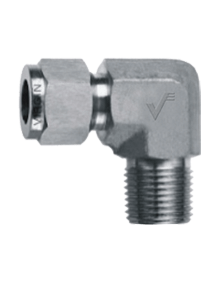

Male Elbow ME

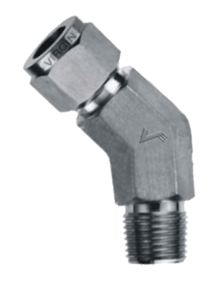

45° Male Elbow 45ME

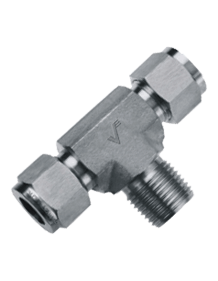

Male Branch Tee MBT

Male Run Tee MRT

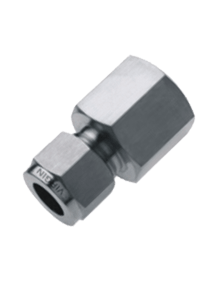

Female Connector FC

Bulk Head Female Connector BFC

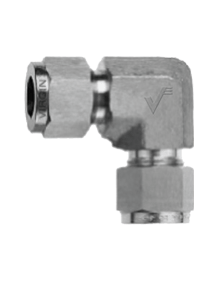

Female Elbow FE

Female Run Tee FRT

Female Branch Tee FBT

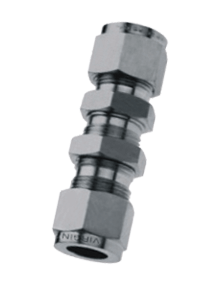

Union U

Reducer Union RU

Bulk Head Union BU

Union Elbow UE

Union Tee UT

Union Cross UC

Reducer R

Bulk Head Reducer BR

Port Connector PC

Male Adapter MA

Female Adapter FA

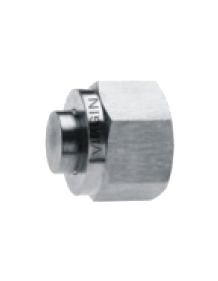

Cap TC

Plug (Port Ends) Tp

Tube Socket Weld Union TSWU

Male Pipe Weld Connector MPWC

Tube Socket Weld Elbow TSWE

Male Pipe Weld Elbow MPWE

Back Ferrule BF

Front Ferrule FF

Popular Searches

parker stainless steel tubing fittings grade 304l, ss 304l instrument tubing standards, ss 304l instrumentation tube fittings price, stainless steel 304l tylok instrumentation fittings, ss 304l instrument fitting size, ss 304l instrumentation valves and fittings india, stainless steel 304l ferrule fittings, ss 304l instrument fittings swagelok, ss 304l duolok tube fittings, ss 304l instrument tubing fittings traders, stainless steel 304l instrument fittings types, stainless steel 304l parker tubing, ss 304l swagelok fittings, ss 304l instrument tube size, stainless steel 304l twin ferrule fittings distributors, stainless steel 304l instrument fitting standards, ss 304l tube fittings stockists, stainless steel 304l instrumentation tube fittings manufacturer in mumbai, buy high quality stainless steel 304l instrument tube fittings, ss 304l instrumentation fittings stockholder, stainless steel 304l compression fittings dealers.

© Copyright | Virgin Engineers 2021. All Right Reserved.