- Home

- Products

- Instrumentation Tube Fittings

- SS 317/317L Instrumentation Tube Fittings

SS 317/317L Instrumentation Tube Fittings

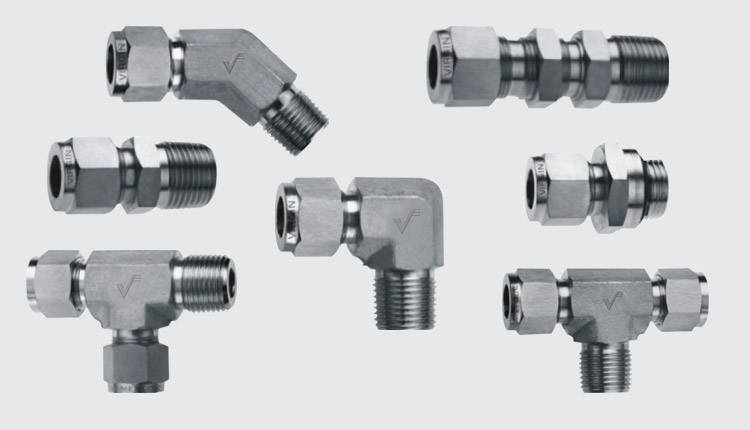

Stainless Steel 317/317L Instrumentation Fittings, SS 317L Double Ferrule Tube Fittings, SS 317 Tube Fittings, UNS S31700 / S31703 Instrumentation Tube Fittings, Stainless Steel 317L Ferrule Fittings, DIN 1.4449/1.4438 Instrumentation Tube Fittings, Grade 317/317L Stainless Steel Single Ferrule Fittings, SS 317 Compression Tube Fittings Manufacturers in Mumbai, India.

Virgin engineers are the leading manufacturer, exporter, and trader of the excellent quality of Stainless steel 317 / 317L instrumentation tube fittings. We have developed all ranges of product at the highly equipped inventory that is resulting in making those greatly reliable and durable as well. These tube fittings are further classified into different categories like austenitic, ferritic and martensitic types that are based upon the crystalline structure. These are delivered to the global industrialists and are used in many industrial applications. It is offered to the buyers at different standards, outer diameter, working pressure and end connections.

SS 317L Female Elbow, 317/317L Male Run Tee, SS 317 Male Elbow, Stainless Steel 317 Male Connector, Grade 317 SS Female Connector, SUS 317L Bulk Head Female Connector Exporters, 317 Male Branch Tee, SS 317L Bulk Head Male Connector Supplier in Mumbai, India.

SS 317L Union Cross, SS 317 Reducer Union, SS 317 Female Run Tee, AISI 317/317L NPT Male Adapters, Stainless Steel 317 Bulk Head Union, SS 317 BSPT Couplings, SS 317 Female Branch Tee, SS 317L Reducer Port Connector – RPC, SS 317L Front Ferrule, SS 317L BSPP Plugs.

Features-

The product is having some good features to offer due to which it has become highly popular among the numbers of industrialists. It has the ability to easily withstand high temperature, vibrations, and shocks. These fittings are having very good creep strength and are resistant to intergranular corrosion because of the addition of niobium alloying element. Also, it resists nitric and mildly acidic solutions.

Alloy information to know-

Alloy SS 317 is austenitic nickel and chromium SS that is having corrosion resistance ability. The high molybdenum content is improving the alloy excellent pitting resistance properties. It is the high corrosion resistant of series 300 and possesses the creep strength and high tensile strength properties at very high temperature.

Alloy SS 317L is low carbon austenitic nickel and chromium stainless steel that is used in the applications wherein annealing is not at all possible after welding and also corrosion resistant is required. The alloy is giving very good oxidation resistance at the intermittent service to 1600 Deg F and in continuous services to 1700 Deg F.

Manufacturing of the tube fittings-

There in the highly equipped industry, the production of Stainless steel 317 / 317L instrumentation tube fittings are done with full care. We have a clear aim of making the superior quality of the product using well tested high quality of the product. There at the time of production of tube fittings, the manufacturers are taking help of newest technology and machinery. This guarantees good dimensional accuracy and fine surface finishes. The designing of it is done by keeping in mind several raw material quality standards and manufacturing norms set up by the producers.

Testing of the tube fittings-

These tube fittings before shipping to the respective buyers are well tested for checking the quality. The testing conducted is like positive material identification test, hardness test, macro test, micro test, intergranular corrosion test, pitting resistance test, chemical test, mechanical test, flattening test, flaring test, etc.

The documents offered-

The documents offered to the buyers are including commercial invoice, packing list, heat treatment chart, quality assurance plan, NABL approved lab test report, etc.

Test certifications-

100% radiography test report, third-party inspection report, buyers report, mill test certifications as per EN 10204/3.1B, etc. are TC offered to the buyers.

Packaging-

To ship Stainless steel 317 / 317L instrumentation tube fittings without causing damage, the packaging is done in wooden cases/plywood boxes, etc.

Specification

Size Range

1/16” 1/2” & 1.5MM to 38.1MM

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - | - | - | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | - | - | - | X2CrNiMo18-15-4 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fi |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Male Connector NPT-M

Male Connector BSP-M

Bulk Head Male Connector BMC

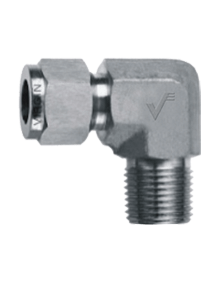

Male Elbow ME

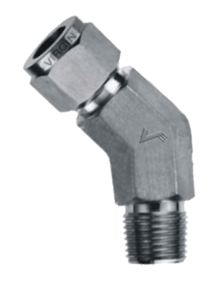

45° Male Elbow 45ME

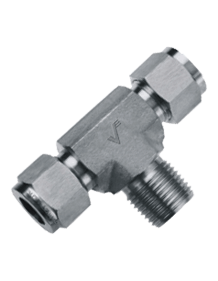

Male Branch Tee MBT

Male Run Tee MRT

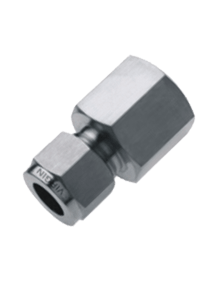

Female Connector FC

Bulk Head Female Connector BFC

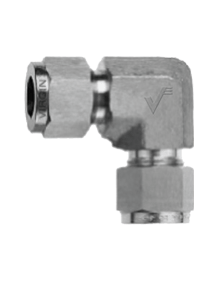

Female Elbow FE

Female Run Tee FRT

Female Branch Tee FBT

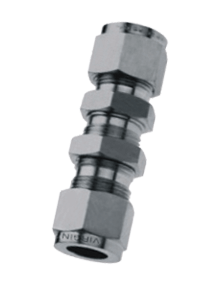

Union U

Reducer Union RU

Bulk Head Union BU

Union Elbow UE

Union Tee UT

Union Cross UC

Reducer R

Bulk Head Reducer BR

Port Connector PC

Male Adapter MA

Female Adapter FA

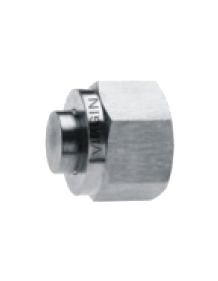

Cap TC

Plug (Port Ends) Tp

Tube Socket Weld Union TSWU

Male Pipe Weld Connector MPWC

Tube Socket Weld Elbow TSWE

Male Pipe Weld Elbow MPWE

Back Ferrule BF

Front Ferrule FF

Popular Searches

ss 317/317l instrumentation valves and fittings india, ss 317l instrumentation tube fittings price, stainless steel 317l ferrule fittings, ss 317l instrument fitting size, stainless steel 317 parker tubing, stainless steel 317 instrument fitting standards, ss 317 tube fittings stockists, stainless steel 317 compression fittings dealers, stainless steel 317l tylok instrumentation fittings, buy high quality stainless steel 317 instrument tube fittings, stainless steel 317l instrumentation tube fittings manufacturer in mumbai, ss 317l instrument tubing standards, ss 317l instrument tubing fittings traders, stainless steel 317l instrument fittings types, ss 317 instrument fittings swagelok, ss 317 instrument tube size, parker stainless steel tubing fittings grade 317, ss 317 swagelok fittings, ss 317l instrumentation fittings stockholder, ss 317 duolok tube fittings, stainless steel 317l twin ferrule fittings distributors.

© Copyright | Virgin Engineers 2021. All Right Reserved.