- Home

- Products

- Instrument Air Header

- SS 316 Instrument Air Header

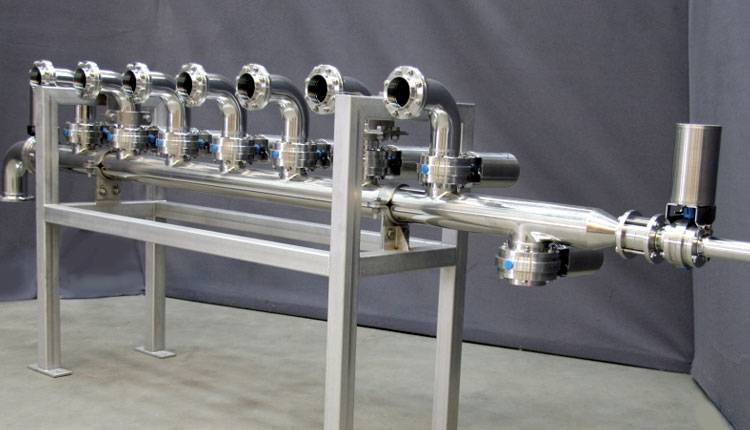

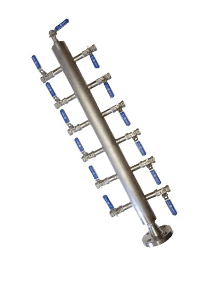

Stainless Steel 316 Instrument Air Header

DIN 1.4401 / 1.4436 Instrument Air Header, 316 Stainless Steel Instrument Air Header, UNS S31600 Instrument Air Header Suppliers, SS Gr.316 Industrial Instrument Air Header, Grade 316 Stainless Steel Instrument Air Header Manufacturers in Mumbai, India.

Air headers act as supplying multiple that offer the users numerous connection alternatives for the isolation manifolds. Basically, these are designed to allocate air from the compressor to the actuators on pneumatic components such as pressure controllers, valve positioners and steam flow meters. For replacing the numerous unit valves assemblies or for operating from one source this air header is the most efficient working device. In other words, these are the substitute for manifolds outlet valves. Moreover, this header provides screw-able inlet link and has a variety of end connection. Based on the end users requirements these air headers are available in a wide configuration, to choose the best range of air header then one must get the Stainless Steel 316 Instrument Air Headers.

Description of grade

Stainless Steel 316 Instrument Air Headers are the components which are often recognized from its standard name UNS S31600 that is the standard molybdenum-bearing grade. It includes a higher amount of molybdenum and nickel content that demonstrate superior corrosion resistant properties in comparison to other grades. The air headers offer superior resistance to crevice and pitting corrosion in chloride atmospheres. However, these also provide excellent tensile, stress rupture and creep strength at elevated temperatures. These alloy of air headers functions well in marine environments where it offers good atmospheric corrosion.

The air headers offer good oxidation resistance in intermittent services up to 870 degrees C while in regular service up to 925 degree C. Moreover these air headers demonstrate superior formability and weldability that is achieved from the conventional fabrication procedure. These are frequently utilized in heavy gauge welded parts. The solution treatment of this air header is done at 1010-1120 degree C and is quickly cool, therefore these are not hardened through thermal treatment.

SS 316 Instrument Air Header Exporters, 316 Stainless Steel Air Headers, SUS 316 RSI Air Headers, Stainless Steel 316 Ped-Lock Air Headers, Grade 316 SS KE Grey Air Header Supplier in Mumbai, India.

316 Stainless Steel SMIPL Air Header, 316 Stainless Steel HYPER VALVES 2" Air Header, SS 316 KE Grey Stainless Steel Air Header, SS 316 INX Polished Air Header, Austenitic Stainless Steel 316 NE Air Headers, AISI 316 Pneumatic Air Headers, SS 316 United Air Header.

Company description

Being one of the leading and veteran ventures we Virgin Engineers are catering to facilitate a standard Stainless Steel 316 Instrument Air Headers all over the globe. As a manufacturer, exporter, and supplier we produce the product by acquiring the best quality of raw material purchased from the valid supplier of the market. Furthermore, we hire the most recent technological tools and equipment to fetch out dimensional accuracy and standard finish in the product.

On the other hand, we are employed with highly qualified professionals and dedicated working force that helps to meet the organization objective. Thus we assure to fulfill each and every desires and requirement of our patrons. We cater our product in a comprehensive range, shapes, length, thickness, and dimensions.

Testing description

To deliver an error and defect free product to the customers we carefully check and examine the entire product range under the control of quality checkers. These testing are like hardness test, pitting resistance test, mechanical analysis, flaring test, macro/micro test, flattening test, chemical analysis, and tensile strength test. Other more tests are an ultrasonic test, radiography test, PMI test, and IGC test.

Packing of product

To avoid the problem of rust and damage throughout transportation the products are properly packed in wooden cases, wooden cartons, and wooden pallets and in boxes.

Specification

Types and Materials

Instrument Air Header, SS 316

Port Size

1/4″ / 1/2″ NB SCH 40 / 80 Nipple Toe. Fitted on outlet ports 1/4″ / 1/2″

Working Pressure :

6000 psi [413 bar]

Size:

Inlet ½ "x Outlet½", Inlet ¾" x Outlet3/4"

Drain Plug

1/2″ SCH 40 / 80 Nipple TOE Fitted with SS Ball Valve & Drain

Outlet ports :

6way / 8way / 12 way / 16way (Staggering or straight, Single sided or Double sided)

Inlet :

DIN & ANSI 1/2″ / 1″ NB Flanged / Threaded Connections.

Main Pipe :

1″, 1-1/2″, 2″ NB SCH 40 / 80.

End Connections :

NPT, BSPT, SW

Temperature rating

PTFE 450 °[232 °c ]/Grafoil-700° F[371° C]

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 11.00 - 14.00 | 67.845 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Ped-Lock Air Headers

KE Grey Air Header

RSI Air Headers

INX Polished Air Header

HYPER VALVES 2 Air Header

SMIPL Air Header

Pneumatic Air Headers

Air Distribution Header

Quality Assurance

Stainless Steel S31600 Instrument Air Header are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 316 Instrument Air Header are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 316 Instrument Air Header mechanical priperties, ss 316 Instrument Air Header traders, stainless steel 316 pneumatic air headers dealers, stainless steel 316 smipl air header, steel 316 Instrument Air Header specification, buy high quality austenitic stainless steel 316 Instrument Air Header, stainless steel 316 ped-lock air headers, ss 316 ke grey stainless steel air header stockists, ss 316 Instrument Air Header stockholder, stainless steel air headers grade 316, stainless steel 316 hyper valves 2" air header types, stainless steel 316 Instrument Air Header distributors, ss 316 Instrument Air Header chemical composition, 316 ss Instrument Air Header, ss 316 ke grey air header, ss 316 ne air headers price, ss 316 Instrument Air Header size, 316 ss inx polished air header size, ss 316 air distribution header india, ss 316 united air header, stainless steel 316 rsi air headers, stainless steel 316 Instrument Air Header standards, 316 ss Instrument Air Header size, stainless steel 316 valtech air headers manufacturer in mumbai.

© Copyright | Virgin Engineers 2025. All Right Reserved.