- Home

- Products

- Needle & Gauge Valves

- Titanium Gr.5 Needle & Gauge Valves

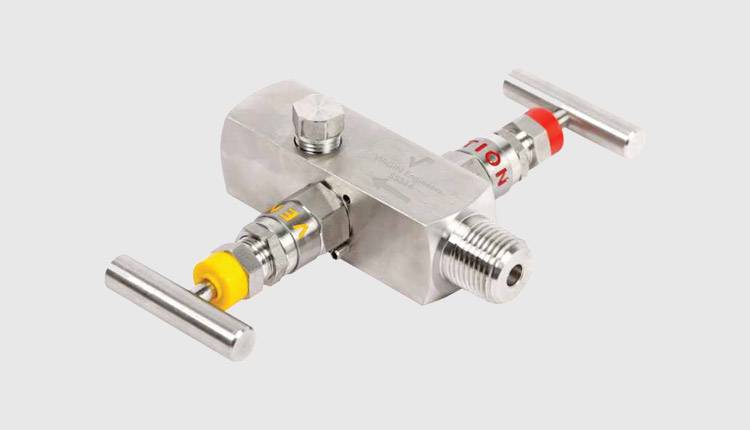

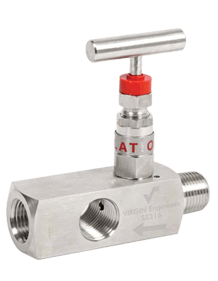

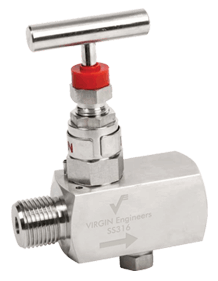

Titanium Gr 5 Needle & Gauge Valves

Titanium Gr 5 Gauge Bleed Needle Valves Suppliers, Titanium Gr 5 Industrial Needle & Gauge Valve, Ti Alloy R56400 Needle & Gauge Valve, DIN 3.7165 Needle & Gauge Valve, Grade 5 Titanium Gauge Valves, Titanium 6Al-4V Needle and Gauge Valves, Titanium Alloy Grade 5 Needle & Gauge Valves Manufacturers in Mumbai, India.

Virgin Engineers convey the finest range of Titanium Gr 5 Needle & Gauge Valves among domestic and international customers. We are providing these valves in various designations, standards, specifications, and shapes. We also stock them in different various treated surface and finishes. As the titanium grade is widely selected in engineering works, the demand for grade 5 is increased. We are manufacturing, distributing, exporting and trading these valves in bulk quantities. It is available in both magnetic and non-magnetic states. On the demand of customers, we offer these in tempered and quenched conditions.

Titanium Alloy Gr 5 Hydraulic Needle Valve, Ti Grade 5 Parker Needle Valve Exporters, Ti6Al4V Screwed End Needle Valve, Ti Alloy Gr. 5 Multiport Gauge Valves, Titanium Gr 5 Gauge Vent Valves Supplier in Mumbai, India.

Titanium Grade 5 Needle Valve, Titanium Gr.5 Gauge Valve, Gr 5 Titanium Alloy Forged Body Gauge Valve, Titanium Gr 5 Integral Bonnet Needle Valve, Titanium Grade 5 Autoclave Needle Valve and Gauge Valves.

Titanium Gr 5 Needle & Gauge Valves Valves is also called 6AI- 4V grade needle and gauge valves. These are the most commonly used valves used in the wide section of engineering and industrial applications. The titanium grade is heat treated to improve its strength. Grade 5 is light weight and has strong structures. This grade is highly formable and resistive to corrosion. It has excellent resistance to pitting and corrosion. It is weldable with all type of welding properties such as arc welding and resistance welding. This grade is manufactured and processed with all standard machines. Grade 5 has higher thermal stability and prevents deformation.

More about Titanium Gr 5 Needle & Gauge Valves:

Grade 5 is an alpha- beta alloy. It is a widely used high strength titanium grade. It has good mechanical property and low density. Grade 5 is treated in small segments. These can be exposed in temperatures up to 400 deg C. It has some amount of oxygen; this composition enhances its fracture toughness and ductility while retaining mechanical properties.

Grade 5 has high strength, low weight ratio, and outstanding resistance to corrosion. Titanium Gr 5 Needle & Gauge Valves have applied on a diversified range of successful applications that required high levels of consistent service. Many industrialists replace those costly and bulky valves with titanium grade valves. When designing valves many aspects are considered such as durability, reliability, and performance.

Grade 5 has many features such as machinability, formability, workability, fabricability and more. It gives an overall performance in a diverse range of low weight applications. Titanium grade can perform in different types of chemicals such as sulfides, nitric acids, phosphoric acids, sulfuric acids, and organic and inorganic compounds. This grade has the ability to form a protective layer on its surface protects from contamination. Grade 5 is a low interstitial titanium alloy. Advantageously, it offers service in the carbide precipitation range. It has immunity to oppose stress corrosion cracking.

Tests that demonstrate the quality of Titanium Gr 5 Needle & Gauge Valves:

Those are Valve seat leakage test, backseat test, closure test, shell leakage test, pneumatic test, hydrostatic test, Cryogenic testing, pitting corrosion test, and low temperature testing. Other tests are burst tests, fire safety tests, relief test, transfer valve test, drill stem test, traveling valve, test intergranular corrosion test, ultrasonic test, radiographic test, etc.

Titanium Gr 5 Needle & Gauge Valves, we deliver in prominent packing of wooden cases, cartons, pallets, and plywood boxes in order to prevent damages.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | UNS | WNR. |

| Titanium Gr 5 | R56400 | 3.7165 |

| Titanium | Ti | C | Fe | H | N | O | Al | V |

| Grade 5 | 90 min | - | 0.25 max | - | - | 0.2 max | 6 min | 4 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.5%Offset) | Elongation |

| 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Titanium Alloy R56400 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Titanium Alloy Gr 5 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

titanium Gr 5 forged body gauge valve types, CP Grade 5 titanium alloy autoclave needle valve manufacturer in mumbai, titanium alloy Gr.5 gauge & needle valve stockholder, titanium grade 5 high pressure gauge valve size, titanium Gr.5 gauge bleed needle valves, titanium alloy Gr 5 parker needle valve india, Gr 5 titanium alloy gauge vent valves, titanium alloy Gr 5 screwed end needle valve stockists, titanium alloy Gr 5 integral bonnet needle valve price, ti gr 5 condensate pots manufacturer supplier titanium alloy Gr 5 needle valve, titanium alloy Gr 5 needle & gauge valve standards, Gr 5 titanium alloy 3 way needle valve dealers, titanium alloy Gr 5 needle shutoff and regulating valves standards, titanium alloy Gr.5 gauge/needle valve traders, ti alloy Gr.5 block & bleed gauge valves, buy high quality commercially pure titanium alloy Gr 5 needle and gauge valve, titanium alloy Gr.5 needle valve distributors, titanium alloy Gr 5 bonnet needle valves size, Grade 5 titanium alloy gauge valve, titanium Gr 5 multiport gauge valves Gr.5, alloy Grade 5 titanium gauge valve.

© Copyright | Virgin Engineers 2021. All Right Reserved.