- Home

- Products

- Valves

- Manifold Valves

- Incoloy 825 Manifold Valves

Incoloy 825 Manifold Valves

Incoloy 825 3 Way Manifold Valves, Incoloy 825 Instrument Manifold Valves, DIN 2.4858 Manifold Valve, Incoloy Alloy 825 5-Way Manifold Valves Suppliers, UNS N08825 Manifold Valves, Incoloy 825 Valve Manifold, Alloy 825 Two Way Manifold Valve Manufacturers in Mumbai, India.

Virgin engineers are a value based company committed to doing the right things at the right time. We are engaged in the field of manifold valves since its introduction in the market. Our mission is to cater to each and every requirement of Incoloy 825 Manifold Valves that are extensively demanded in the global markets. These are prominent for heavy engineering applications because of its properties. Our values orientation plays out in everything from supplying chain management to engineering sales, service, manufacturing, and fulfillment.

Incoloy 825 Manifold Valves are nickel, iron and chromium alloy with some amount of titanium, copper, and molybdenum. The chemical composition of the alloy is designed to offer great resistance to corrosive environments. This grade is similar to standard grade offer resistance to aqueous corrosion. This offers outstanding service in reducing and oxidizing environments, local attacks of pitting and crevice corrosion, stress corrosion cracking and more. This grade is resistive to different types of chemical compounds such as phosphoric acids and sulfuric acids.

Incoloy grad has excellent mechanical properties from higher to moderate temperatures. It can be exposed to temperatures above 1000 deg F that leads to change in the microstructure of alloy; also it may lead to a change in ductility and impact strength. It is not used where higher temperature creep and rupture properties are a concern. These are readily strengthened by cold working operations.

Incoloy 825 Hydraulic Manifold, Incoloy 825 Remote-Mount, Incoloy 825 Three Way T- Type Manifold Valves, Incoloy 825 Double Block Bleed Valves, Incoloy 825 Instrumentation Manifold Valves, Incoloy 825 H Series Manifold Valves, Alloy 825 Bellows Sealed Manifolds, Incoloy 825 R - Type Manifold Valve.

Incoloy 825 Valves Manifolds, Incoloy 825 Direct-Mount Manifolds Exporters, Incoloy 825 Remote-Mount Manifold Valve, Incoloy 825 Block and Bleed Valves, Incoloy 825 2 Valve Manifold, Incoloy Alloy 825 3 Valve Manifold, Incoloy 825 Five Valve Manifold Supplier in Mumbai, India.

Our manifolds:-

Incoloy manifold valves are designed for static pressure, differential pressure applications and liquid levels. It is offered in standard or compact inline body design, direct mounting, for use in the instrument, module system, and remote mount. It is used in compact assembly design that results in decreased weight and size. Incoloy manifold valves have fewer leak points. These are easy to install and maintain.

Material qualification of Incoloy 825 Manifold Valves:-

From starting the production at the last stage, our technically skilled employees keep a constant eye on operations. We execute quality assurance plans to maintain the highest level of superiority. Quality control measures are guided by professionals under international norms. The primary tests performed by us are intergranular corrosion test, backseat test, closure test, valve seat leakage test, radiographic test, cryogenic testing, and temperature test. other tests are shell leakage test, pneumatic test, hydrostatic test, burst tests, fire safe tests, functional tests, drill stem test, traveling valve test, ultrasonic test, pitting corrosion test, etc.

Test certificates and reports:-

The certificates provided to customers are attested certificate by third parties, stamping details, fumigation certificates, heat treatment charts, QAP, specification guide, and packaging details. Other reports are national board approval lab (NBAL) test report, raw material test report, mill test report, Commercial invoice, MTC report, etc.

Packaging norms:-

We provide different packaging options to the customers such as plywood crates, cases, cartons, pallets, and boxes. Individual packing is covered with a thin film of plastic that offers protection from oxidation while exporting. Moreover, we provide customized packing options to the customer as per their requirements.

Incoloy 825 Manifold Valves are available in altered dimensions; customers will get only from us.

Specification

ASTM

ASTM A494 / ASME SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| incoloy 825 | N08825 | 2.4858 | NFE30C20DUM | NiCr21Mo | NCF 825 | NA 16 | ЭП703 | XH38BT |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Ai | Ti |

| Incoloy 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000, MPa – 550 | Psi – 32,000, MPa – 220 | 30 % |

Products

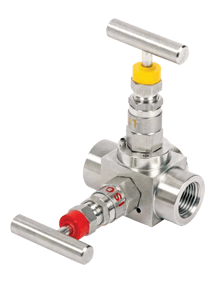

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

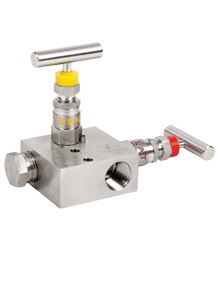

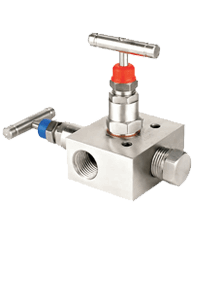

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

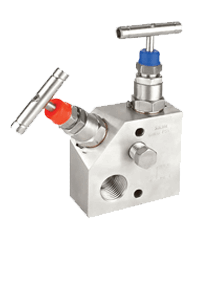

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Incoloy N08825 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Incoloy 825 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

incoloy 825 manifold valves manufacturer in mumbai, incoloy 825 manifold valves manufacturers in india, incoloy 825 manifold hydraulic valves, incoloy 825 manifold valves stockholder, alloy 825 manifold valves stockists, incoloy 825 manifold valves types, incoloy 825 manifold 3 valves 2 ways, incoloy 825 types of manifold valves, incoloy 825 2 way manifold valve for pressure gauge, buy high quality incoloy 825 manifold valves, incoloy 825 valve remote mounted, incoloy 825 manifold 2 valve t type manifold valve, incoloy 825 manifold valve size, incoloy 825 manifold valves distributors, incoloy 825 3 valve direct mounted, incoloy 825 manifold mounted ball valves, incoloy alloy 825 3 way manifold price list, incoloy 825 manifold valve dealers, incoloy 825 manifold valve application, incoloy 825 manifold valves price, incoloy 825 manifold valves traders.

© Copyright | Virgin Engineers 2025. All Right Reserved.