- Home

- Products

- Valves

- Manifold Valves

- Inconel 600 Manifold Valves

Inconel 600 Manifold Valves

Inconel 600 Valve Manifold, Inconel 600 3 Way Manifold Valves, UNS N06600 Manifold Valves, Inconel Alloy 600 5 Way Manifold Valves Suppliers, Alloy 600 2 Way Manifold Valve, DIN 2.4816 Manifold Valve, Inconel 600 Instrument Manifold Valves Manufacturers in Mumbai, India.

Virgin engineers due to good years of working experience in the same sector are offering the high quality of Inconel 600 manifold valves to the national and international buyers. We are worldwide dealing as a reputable manufacturer, supplier, stockiest and exporter of the manifold valves to the buyers so that all application desires are fulfilled and in all parts of the globe the product can be delivered. With the aim of satisfying the customers, our industry as a producer is making and offering the product in standard specifications that vary in sizes, connections, flow pattern, end connections, working pressure, temperature rating, etc.

Inconel 600 is chromium and nickel-based alloy with very good resistance to oxidation at high temperature and also at chloride containing atmospheres. The alloy is designed for the use from the cryogenic to the elevated temperature ranging 1093 Deg C. The high content of nickel enables it in retaining the resistance under the reducing conditions and thus making it corrosion resistant by several inorganic and organic compounds. The nickel content is providing very good resistant to chloride ion stress corrosion cracking and also it provides very good resistant at the alkaline solutions. The chromium content provides the alloy resistant to the sulfur compound and several oxidizing atmospheres. The chromium content of the alloy is making it greatly superior to the commercially pure nickel into an oxidizing situation. At the strong oxidizing solution like concentrated nitric acid, alloy 600 is having the very bad resistant. Moreover, this alloy is not attacked by the numbers of neutral as well as alkaline salt solutions and also can be used in the caustic atmosphere. This alloy is resisting steam and steam mixture, carbon dioxide, etc. Alloy 600 is actually a non-magnetic in nature. It is having very good mechanical properties and high tensile strength, good workability and is weldable readily. This alloy is also exhibiting cold forming features normally when associated with the chromium-nickel SS.

Inconel 600 R - Type Manifold Valve, Inconel 600 Instrumentation Manifold Valves, Inconel 600 Remote-Mount, Inconel 600 Three Way T- Type Manifold Valves, Inconel 600 H Series Manifold Valves, Alloy 600 Bellows Sealed Manifolds, Inconel 600 Block and Bleed Valves, Inconel 600 Hydraulic Manifold, Inconel 600 Double Block Bleed Valves.

Inconel Alloy 600 3 Valve Manifold, Inconel 600 2 Valve Manifold, Inconel 600 Direct-Mount Manifolds Exporters, Inconel 600 Remote-Mount Manifold Valve, Inconel 600 5 Valve Manifold, Inconel 600 Valves Manifolds Supplier in Mumbai, India.

Production process details-

There at the manufacturing unit, the manufacturing of Inconel 600 manifold valves are executed only by using the high quality of raw materials collected from reliable market vendors. The use of advanced technology and modern tools have helped the products to make 100% perfect quality of product assuring dimensional accuracy and smooth surface finishes. We design the product by keeping in mind product fabrication guidelines and national and international product quality standards.

Documentations of Inconel 600 manifold valves

When the ordered consignment is delivered to the buyers the documents are essentially provided to them. This is enough to clear the buyers about product reliability and quality. Documents including heat treatment chart, quality assurance plan, packaging list, raw material test report, material traceability report, guarantee letter, NABL approved lab test report, etc. Moreover, the TC including buyers report, third-party test report, radiography test report, the raw material certificate is provided to the buyers.

Packaging of Inconel 600 manifold valves

To assure safer delivering of the Inconel 600 manifold valves, its packaging is done into plywood/carton boxes and individually wrapped into environmental poly bags.

Specification

ASTM

ASTM A494 / ASME SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | NiCr15Fe | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | 655 MPa, 95000 psi | 310 MPa, 45000 psi | 45 % |

Products

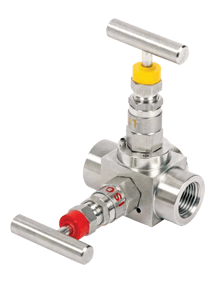

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

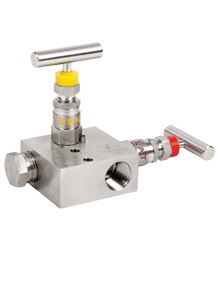

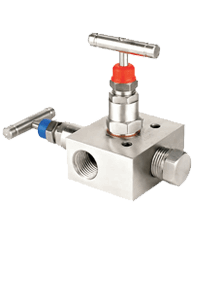

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

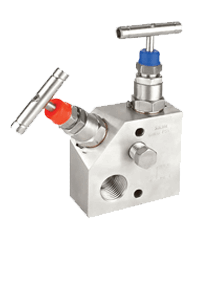

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Inconel N06600 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 600 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 600 2 way manifold valve for pressure gauge, inconel 600 types of manifold valves, inconel 600 manifold hydraulic valves, inconel 600 3 valve direct mounted, inconel 600 manifold valves traders, inconel 600 manifold valves manufacturers in india, inconel alloy 600 2 valve t type manifold valve, buy high quality inconel 600 manifold valves, inconel 600 manifold valve size, inconel 600 manifold valve application, inconel 600 5 valve remote mounted, inconel 600 3 way manifold price list, alloy 600 manifold valves stockists, inconel 600 manifold valves types, inconel 600 manifold valves manufacturer in mumbai, inconel 600 manifold valves stockholder, inconel 600 manifold valves distributors, inconel 600 manifold valve dealers, inconel 600 manifold valves price, inconel 600 manifold 3 valves 2 ways, inconel 600 manifold mounted ball valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.