- Home

- Products

- Valves

- Manifold Valves

- Inconel 601 Manifold Valves

Inconel 601 Manifold Valves

Inconel 601 3 Way Manifold Valves, Inconel 601 Valve Manifold, Inconel 601 Instrument Manifold Valves, UNS N06601 Manifold Valves, Alloy 601 2 Way Manifold Valve, Inconel Alloy 601 5 Way Manifold Valves Suppliers, DIN 2.4851 Manifold Valve Manufacturers in Mumbai, India.

Virgin engineers Inconel 601 manifold valves come with the awesome features to offers like high-grade quality and superiority in its performances. The offered ranges of valves are blended with silent attributes like long-lastingness, low maintenance, and superior quality. We easily customize these grade manifold valves in different wall thickness and sizes based upon the requirements of the clientele. We are the leading manufacturer, supplier, stockiest and exporter that is offering the product in standard specifications that very in standards, end connection, size, pressure rating, and types, etc.

We are professional dealer of the valves can easily provide the product of high quality at reasonable rates. We bring comprehensive ranges of valves that are used in many industrial applications. We also continue to provide the robust quality of valves along with the premium quality of services to the buyers all across the globe. There are many good reasons why one can deal with this industry is like available inventory, customized manufacturing, quality product, competitive price, on-time delivery, and rapid factory.

Inconel 601 Block and Bleed Valves, Inconel 601 H Series Manifold Valves, Inconel 601 Three Way T- Type Manifold Valves, Inconel 601 Hydraulic Manifold, Inconel 601 Instrumentation Manifold Valves, Inconel Alloy 601 Bellows Sealed Manifolds, Inconel 601 R - Type Manifold Valve, Inconel 601 Remote-Mount, Inconel 601 Double Block Bleed Valves.

Inconel 601 5 Valve Manifold, Inconel Alloy 601 3 Valve Manifold, Inconel 601 Direct-Mount Manifolds Exporters, Inconel 601 Valves Manifolds, Inconel 601 Remote-Mount Manifold Valve, Inconel 601 2 Valve Manifold Supplier in Mumbai, India.

Our industry is having highly skilled and trained personnel with which the production of the Inconel 601 Manifold valves is guaranteed to be highly effective. The professional team is hired that at all the stages of production is guiding the workers in developing the high quality of valves so that it can be used at high-temperature surrounding. We are making effective use of available latest technology as well as modern tools that help the dealer to offer the valves that are assuring smooth edges and accuracy in dimensions. Furthermore, the product is developed by keeping in mind several product quality standards and according to the set manufacturing techniques.

Inconel 601 alloy is the chromium and nickel-based alloy that is used for the applications that need heat and corrosion resistance. This nickel alloy has today stood out very well in the market because of its resistance to high-temperature oxidations, remaining oxidation resistant through 2200 Deg F. This alloy develops very tight adherent oxide scale that resists spalling and retains ductility even after getting exposed to long service life. The alloy also possesses very good aqueous corrosion resistance, readily formed/welded/machined and has high mechanical strength. This makes it be used at many industrial applications all across the globe. It works against grain boundary precipitation.

The testing of the manufactured ranges of Inconel 601 manifold valves is done at the manufacturing unit with the clear aim of checking the quality of the product. Tests like PMI test, hardness test, pitting resistance test, chemical analysis, mechanical test, etc are conducted. Thus no defected or ineffective quality of valves is provided to the buyers.

There are many documents that are provided by us when the ordered consignment is delivered to the respective buyers. Fumigation certificate, heat treatment chart, quality assurance plan, packaging list, guarantee letter, raw material test report, material traceability report, NABL approved lab test report, MTC as per EN 10204/3.1B, radiography test report, etc is offered to the buyers.

Specification

ASTM

ASTM A494 / ASME SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | NiCr23Fe | NCF 601 | NA 49 | XH60BT | - |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.00 max | 0.50 max | 0.015 max | 1.00 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000, MPa – 550 | Psi – 30,000, MPa – 205 | 30 % |

Products

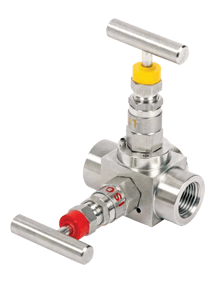

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

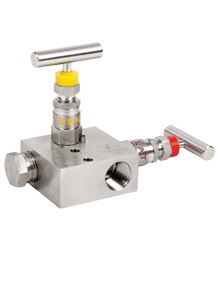

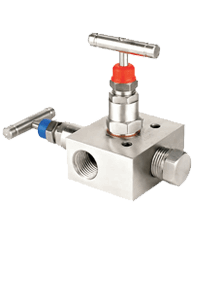

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

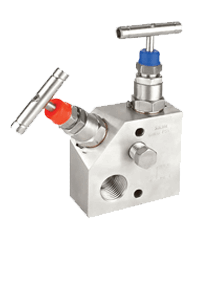

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Inconel N06601 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 601 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 601 2 way manifold valve for pressure gauge, inconel 601 5 valve remote mounted, inconel 601 manifold valve application, inconel 601 types of manifold valves, inconel 601 manifold valves traders, inconel 601 manifold valves stockholder, inconel 601 manifold hydraulic valves, inconel 601 manifold mounted ball valves, inconel 601 3 valve direct mounted, inconel 601 manifold 3 valves 2 ways, alloy 601 manifold valves stockists, inconel 601 manifold valve dealers, inconel 601 manifold valves price, buy high quality inconel 601 manifold valves, inconel 601 manifold valves distributors, inconel 601 manifold valve size, inconel 601 manifold valves manufacturer in mumbai, inconel 601 manifold 2 valve t type manifold valve, inconel 601 3 way manifold price list, inconel 601 manifold valves manufacturers in india, inconel 601 manifold valves types.

© Copyright | Virgin Engineers 2021. All Right Reserved.