- Home

- Products

- Valves

- Manifold Valves

- Inconel 625 Manifold Valves

Inconel 625 Manifold Valves

Inconel 625 3 Way Manifold Valves, Inconel Alloy 625 5 Way Manifold Valves Suppliers, Inconel 625 Instrument Manifold Valves, UNS N06625 Manifold Valves, DIN 2.4856 Manifold Valve, Inconel 625 Valve Manifold, Alloy 625 2 Way Manifold Valve Manufacturers in Mumbai, India.

Virgin engineers are one of the manufacturer and supplier of Inconel 625 Manifold Valves and other non-ferrous grade products. To attain leadership in position in the through performance excellence by providing cost effective valves options to the customers. In order to supply high quality manifold valve products, we are providing ancillary services and solutions to worldwide clients while using innovative tech which is eco-friendly that motivate our employees to focus on continuous improvement and achieve highest business standards. We stock these manifold valves are manufactured in the standard designations, standards, custom dimensions and non-standard dimensions demanded by the customers.

It is a nickel, niobium and molybdenum content offering excellent resistance to many corrosive media. In the soft annealed condition in temperature between 950 deg C to 1050 deg C, it is used for the wet corrosion applications even in the high pressure zones. For the higher temperature application above 600 deg C the solution annealed version is preferred. The strength of Inconel 625 Manifold Valves can be enhanced by heat treatment.

Inconel 625 Hydraulic Manifold, Inconel 625 Remote-Mount, Inconel 625 Three Way T- Type Manifold Valves, Inconel 625 Instrumentation Manifold Valves, Inconel 625 H Series Manifold Valves, Inconel Alloy 625 Block and Bleed Valves, Alloy 625 Bellows Sealed Manifolds, Inconel 625 R - Type Manifold Valve.

Inconel 625 5 Valve Manifold, Inconel 625 Valves Manifolds, Inconel 625 Double Block Bleed Valves, Inconel 625 Two Valve Manifold, Inconel Alloy 625 3 Valve Manifold, Inconel 625 Direct-Mount Manifolds Exporters, Inconel 625 Remote-Mount Manifold Valve Supplier in Mumbai, India.

Resistibility of Inconel 625 grade:-

It has optimum corrosion resistance can only be obtained when the material has the correct materials conditions and having a clean structure. Under the same conditions in the soft annealed conditions has excellent corrosion resistance to a variety of corrosive media. It has excellent resistance to crevice and pitting corrosion in the concentrated chlorides media. Inconel 625 is virtually immune to chloride induced stress corrosion cracking. It has resistance to corrosion attack by several chemicals such as nitric acid, phosphoric acid, sulfuric acids, and hydrochloric acid. Even it can expose in the higher levels of concentrated alkalis and organic acids under both oxidizing and reducing conditions.

It possesses the same resistance ability after weld heat treatments.

Quality standards customers have to know:

Our objective is to complete customer satisfaction. We provide our clients with products that meet all requirements demanded by them. We create quality objectives at each level to ensure those customer requirements are addressed or not. We are fully committed to the continuous growth of production method as a strategic approach to achieve the highest quality objectives. Our quality norms are reviewed and communicated to all employees on a regular basis.

Here our employees are stick and contribute to the efficiency of the quality system in every aspect of our business. We are committed to provide our clients with uncompromising quality and service. This is possible through a team approach where all the employees of the company objectives and work within their own discipline to make the production better.

To verify the supply made products are made exactly as per the client's specification we do different types of tests. Those are valve seat leakage test, mechanical test, backseat test, closure test, compression test, shell leakage test, hydrostatic test, cryogenic testing, burst tests, fire safe tests, and relief test. Other tests are transferred valve test, drill stem test, (TV) test, intergranular corrosion test, ultrasonic test, radiographic test, pneumatic test, pitting corrosion test, and more.

Specification

ASTM

ASTM A494 / ASME SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | NiCr22Mo9Nb | NCF 625 | NA 21 | ХН75МБТЮ | - |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 1.00 max | 5.0 max | 58.0 min | 20.0 - 23.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000, MPa – 930 | Psi – 75,000, MPa – 517 | 42.5 % |

Products

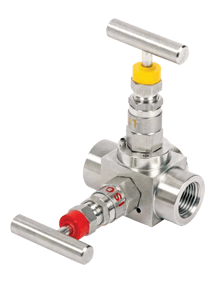

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

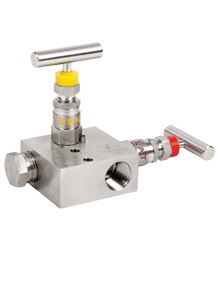

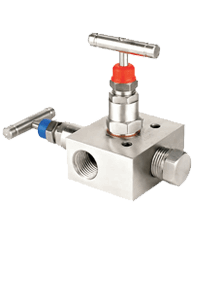

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

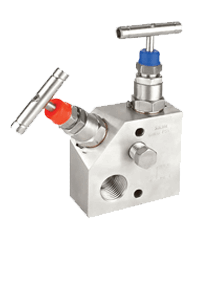

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Inconel N06625 Manifold Valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 625 Manifold Valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 625 types of manifold valves, inconel 625 manifold hydraulic valves, inconel 625 manifold valves price, inconel 625 manifold 3 valves 2 ways, inconel 625 manifold mounted ball valves, inconel 625 manifold valves traders, inconel 625 2 way manifold valve for pressure gauge, inconel 625 manifold valves manufacturers in india, inconel 625 manifold 2 valve t type manifold valve, inconel 625 valve remote mounted, inconel 625 manifold valve size, alloy 625 manifold valves stockists, inconel 625 manifold valve dealers, inconel 625 manifold valve application, inconel 625 manifold valves manufacturer in mumbai, inconel 625 manifold valves types, inconel 625 3 way manifold price list, inconel 625 3 valve direct mounted, buy high quality inconel 625 manifold valves, inconel 625 manifold valves stockholder, inconel 625 manifold valves distributors.

© Copyright | Virgin Engineers 2021. All Right Reserved.