- Home

- Products

- Needle & Gauge Valves

- Monel Alloy 400 Needle & Gauge Valves

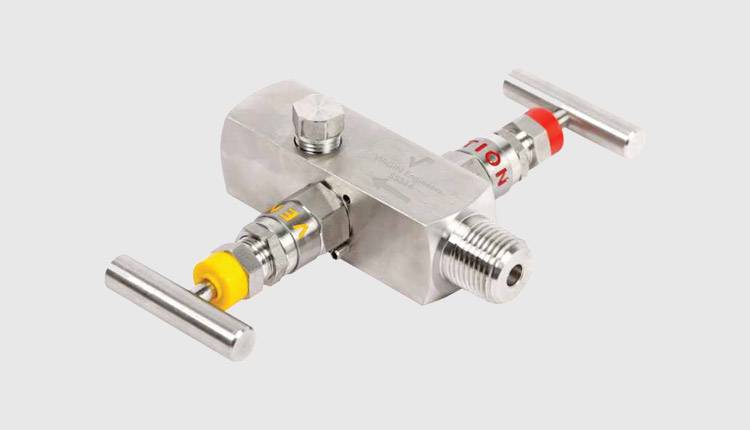

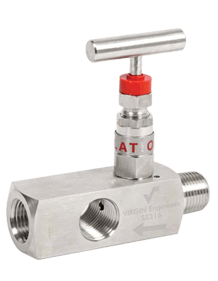

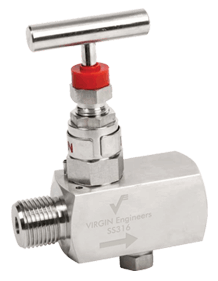

Monel 400 Needle & Gauge Valves

Monel 400 Gauge Bleed Needle Valves Suppliers, UNS N04400 Needle & Gauge Valve, DIN 2.4360 Needle & Gauge Valves, Alloy 400 Industrial Needle & Gauge Valve, Monel 400 Gauge Valves, Monel Alloy 400 Needle & Gauge Valve Manufacturers in Mumbai, India.

Virgin engineers are one of the reputed and ISO 9001:2008 certified manufacturing company that manufactures and supply high quality of Monel 400 Needle & Gauge Valves in India but export it worldwide. The valves are made of high-quality material or forging process and are made available to customers in different sizes, end connections, sealing styles and stem types as well as in angle and straight patterns. Being one of the esteemed manufacturing companies, we are fully capable of providing our patron’s needle and gauge valves for all types of high to medium to low pressure as well as temperature applications.

The needle and Gauge valves manufactured by our qualified professionals are made using bar material and have good working pressure that is equivalent to the straight seamless pipes. We make use of bar stock for making these valves. The raw material that we use is fully traceable and tested. We manufacture these valves using quality tested raw material such as Monel. All these materials ensure that the manufactured valves have high strength, resistance against pressure and temperature and are highly durable.

Moreover, to ensure the quality needle valve, we test conduct different tests at 6000 PSI. We manufacture and export these valves in a huge variety of materials and Monel is one of the popular materials used for manufacturing. These valves are used for various process systems, research applications, and analytical instrumentations.

Monel 400 Screwed End Needle Valve, Monel 400 Hydraulic Needle Valve, 400 Monel Parker Needle Valve, Monel 400 Gauge Vent Valves Exporters, Monel Alloy 400 Multiport Gauge Valves Supplier in Mumbai, India.

Monel 400 Gauge Valve, Monel Alloy 400 Needle Valve, Monel 400 Needle / Gauge Valves, Monel 400 Forged Body Gauge Valve, Monel Alloy 400 Integral Bonnet Needle Valve, Monel 400 Autoclave Needle Valve Needle and Gauge Valves.

Other details about Monel 400 Needle & Gauge Valves

These valves are available to customers in different shapes, sizes, and forms as per the requirement and demand. These valves are made in such a way that it can easily bear temperature of up to 232 deg C that is 450 deg F. however, talking about Monel 400; it is a copper and nickel-based alloy that is highly resistant to steam and seawater at high temperature and caustic solutions. The alloy is basically a solid solution that can be easily hardened through the cold working process.

On the other hand, the nickel alloy demonstrates different features like good weldability, good corrosion resistance, and high strength. It even has good physical properties, is high strength, hardness and high temperature resistant.

Testing and packaging

Well, talking about the testing and packaging process, these two processes considered the most important as they help us know whether the manufactured product is of good quality or not. Therefore, to check Monel 400 Needle & Gauge Valves performance there are several tests done like hardness test, flattening test, intergranular corrosion test, positive material identification test, pitting resistance test and more.

All the tests are done to ensure compliance with the customer’s requirement and international standards. In addition to this, strict supervision is given at the time of testing so that no damaged product is delivered to the customers. At last, these Monel 400 Needle & Gauge Valves are packed in PTFE and Grafoil packaging material and delivered to customers with raw material test certificate, manufacturer test certificate in accordance to EN 10204/3.1 and third-party inspection report.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Monel N04400 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Monel 400 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

monel 400 gauge valve, alloy 400 forged body gauge valve types, monel alloy multiport gauge valves grade 400, monel 400 3 way needle valve dealers, monel 400 needle valve distributors, monel 400 alloy high pressure gauge valve size, buy high quality monel 400 needle and gauge valve, monel 400 alloy gauge valve, monel 400 gauge vent valves, monel 400 gauge & needle valve stockholder, monel 400 parker needle valve india, monel 400 screwed end needle valve stockists, monel 400 block & bleed gauge valves, monel® 400 bonnet needle valves size, monel 400 needle & gauge valve standards, monel® alloy 400 gauge bleed needle valves, monel 400 needle shutoff and regulating valves standards, monel alloy 400 autoclave needle valve manufacturer in mumbai, monel alloy 400 integral bonnet needle valve price, monel alloy 400 gauge/needle valve traders. monel 400 condensate pots manufacturer supplier hydraulic needle valve.

© Copyright | Virgin Engineers 2025. All Right Reserved.